Torque converter

A technology for torque converters and gearboxes, which is applied in the direction of fluid transmission devices, belts/chains/gears, mechanical equipment, etc., to achieve the effects of increasing the flow channel area, smooth flow, and increasing capacity coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

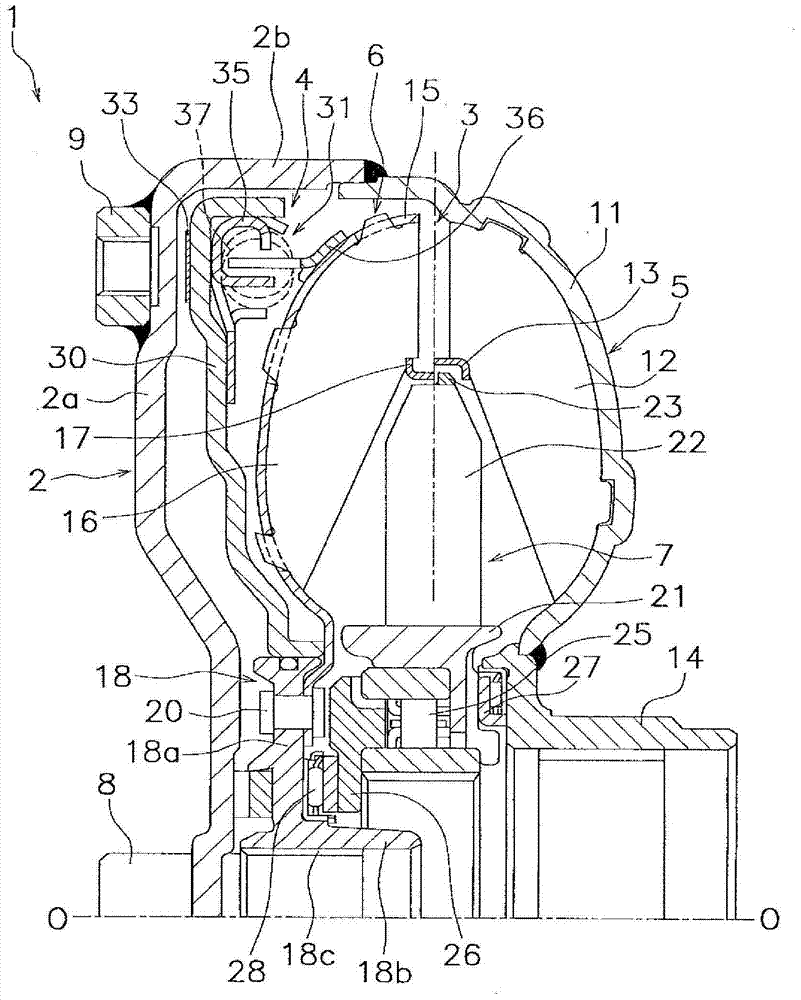

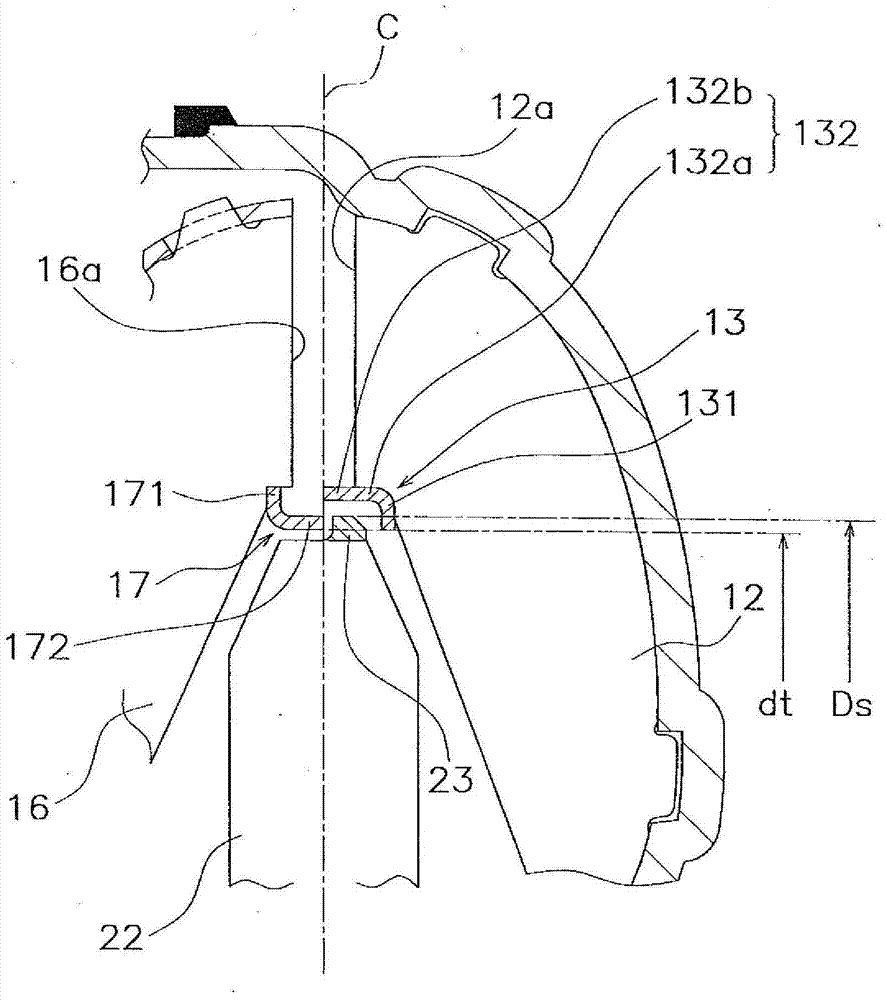

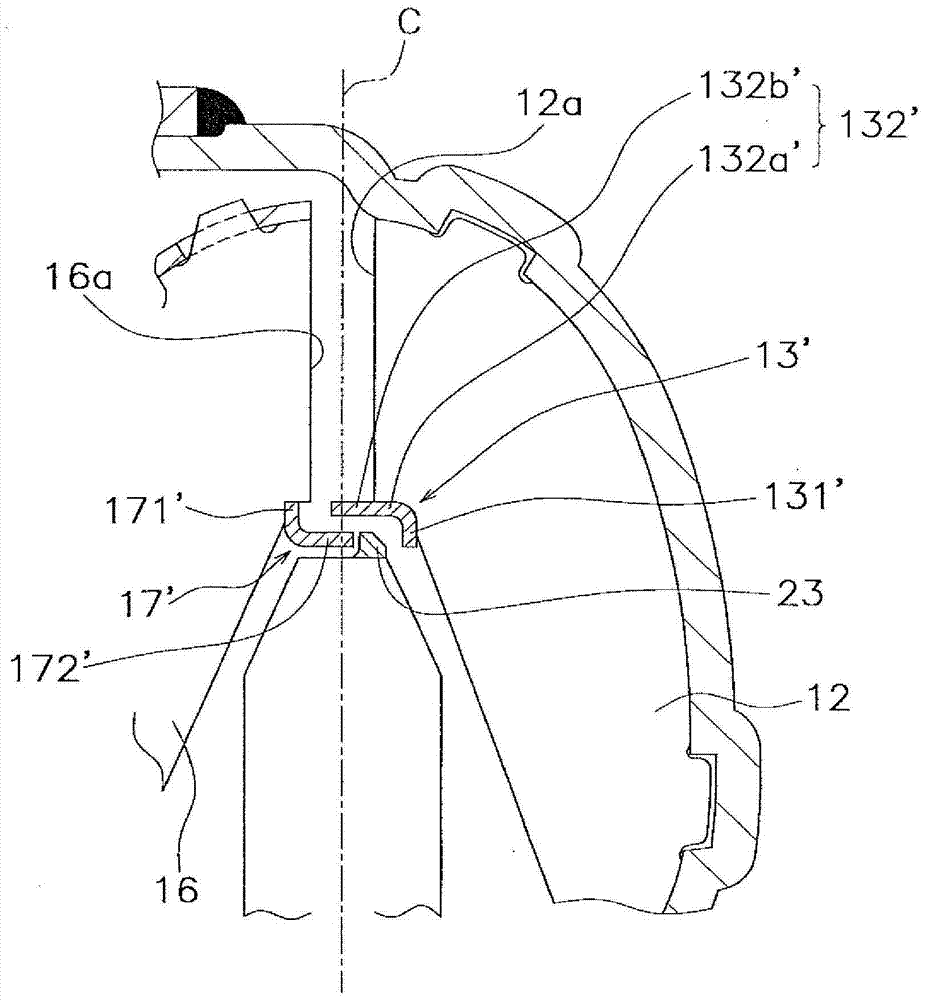

[0025] [Basic structure of torque converter]

[0026] figure 1 The illustrated torque converter 1 is a device for transmitting power from a crankshaft (not shown) of an engine to an input shaft (not shown) of a transmission. figure 1 The left side is equipped with an engine not shown in the figure, figure 1 The right side is equipped with a gearbox not shown in the figure. figure 1 The O-O line shown is the axis of rotation of the torque converter 1 .

[0027] Such as figure 1 As shown, the torque converter 1 is composed of a front cover 2 , a torque converter main body 3 and a locking device 4 . The torque converter body 3 has an impeller 5 , a turbine 6 , and a stator 7 .

[0028] The front cover 2 has a disc portion 2a and an outer peripheral cylindrical portion 2b. A center hub 8 extending toward the engine side is fixed to the inner peripheral portion of the disc portion 2a. Also, on the engine side of the outer peripheral portion of the circular plate 2a, a plural...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com