An automatic gas pressurization device

A technology of gas pressurization and equipment, applied in the direction of electric fluid pressure control, etc., can solve the problems of not being able to use multiple pressures for filling, low safety factor, waste of energy, etc., to achieve easy observation and operation, safe and reliable quality , to ensure the effect of supercharging speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

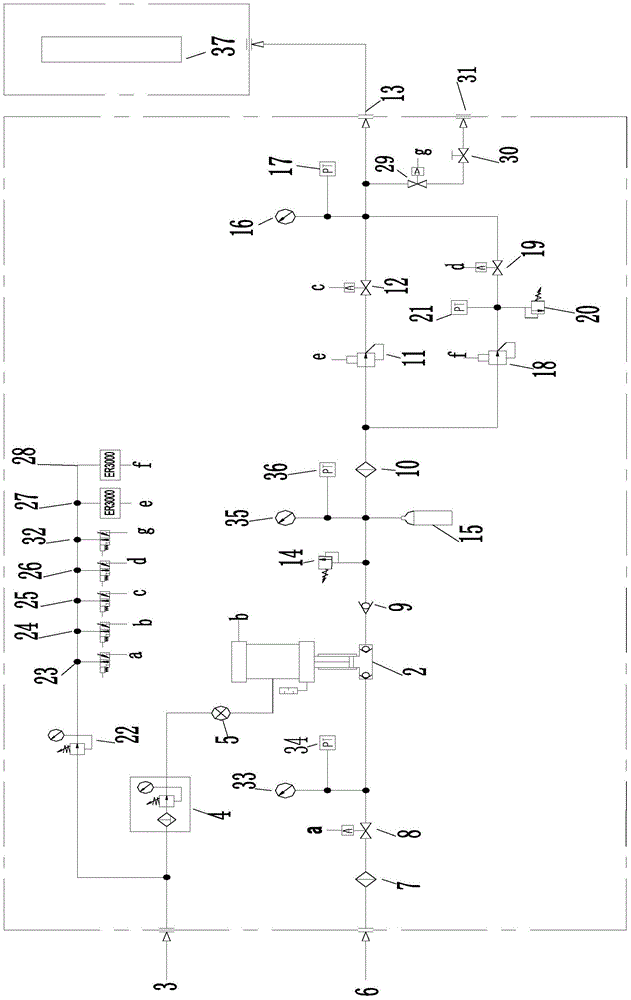

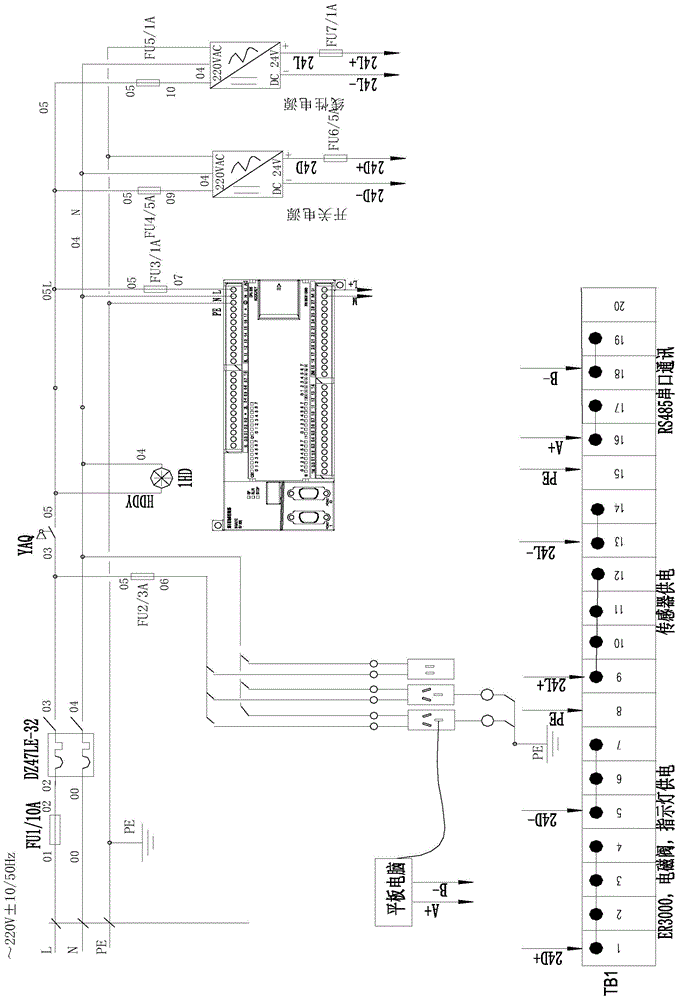

[0025] Such as Figure 1-5 As shown, an automatic gas pressurization device described in the embodiment of the present invention includes a cabinet 1, and the cabinet 1 is provided with a control unit, a pipeline unit and a power supply, and the power supply device in the control unit and the pipeline unit All are connected to the power supply, the control unit includes a host computer and a PLC controller, and the host computer is connected to the PLC controller through a communication cable; the pipeline unit includes a driving gas input pipeline, a gas input pipeline , a gas-driven booster pump 2 and a high-pressure gas output pipeline; the driving gas input pipeline is sequentially connected in series with a driving gas input source 3, a filter pressure reducing valve 4, and a speed regulating valve 5, and the output end of the speed regulating valve 5 It is connected with the driving gas input interface of the gas-driven booster pump 2; the gas input pipeline is sequentia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com