A control method for realizing energy saving of vibrating monitoring equipment

A control method and technology for monitoring equipment, applied in electrical program control, program control in sequence/logic controllers, etc., can solve problems such as energy waste, vibration monitoring equipment without energy-saving measures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

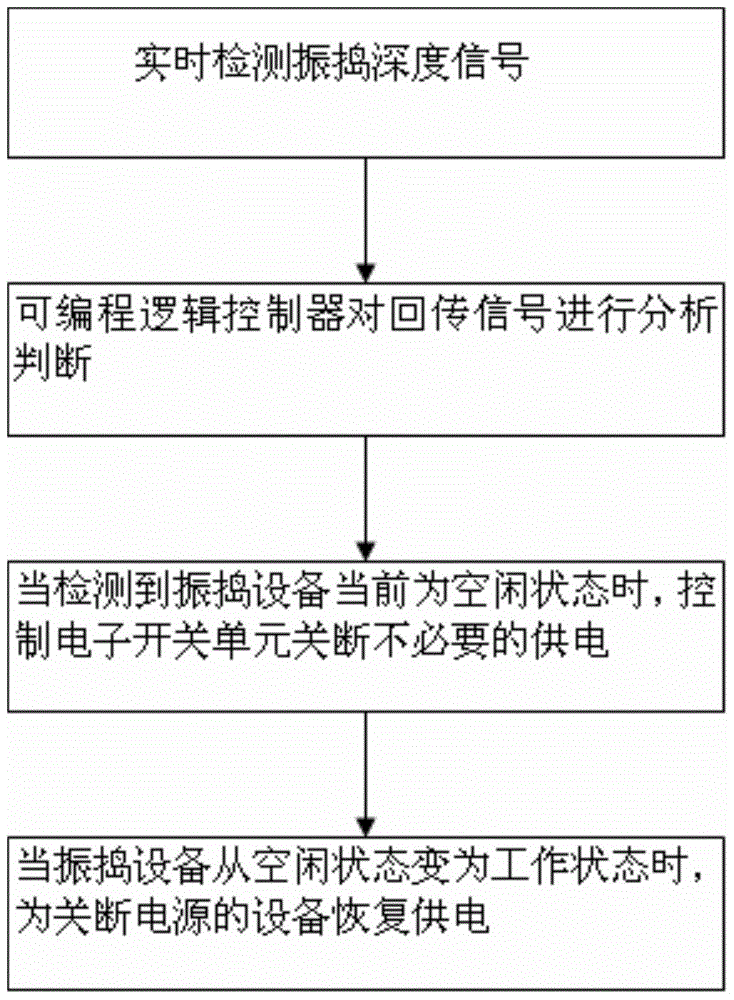

[0019] The invention aims at proposing a control method for realizing energy saving of vibrating monitoring equipment, so as to solve the problem that the traditional technology has no effective energy-saving measures for vibrating monitoring equipment, resulting in energy waste. In the present invention, the current state of the vibrating equipment (whether the vibrating equipment is in use) is automatically obtained through the ultrasonic sensor on the vibrating equipment, and the power channel of the idle equipment is automatically cut off to save energy; and the vibrating equipment can be automatically obtained to resume use Premonition signal (detection of the vibrator ultrasonic sensor), so as to automatically restore the equipment that has been cut off from the power supply and restore it to working condition.

[0020] Below in conjunction with accompanying drawing and embodiment the scheme of the present invention will be further described:

[0021] like figure 1 As s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com