A rotary led spotlight and its assembly method

A LED spotlight, rotating technology, applied in lighting devices, fixed lighting devices, lighting auxiliary devices, etc., can solve the problems of LED spotlights such as poor heat dissipation performance, complicated assembly process, and limited use occasions, and achieve safe and reliable connection strength , good heat dissipation performance, and the effect of reducing the cost of the whole lamp

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

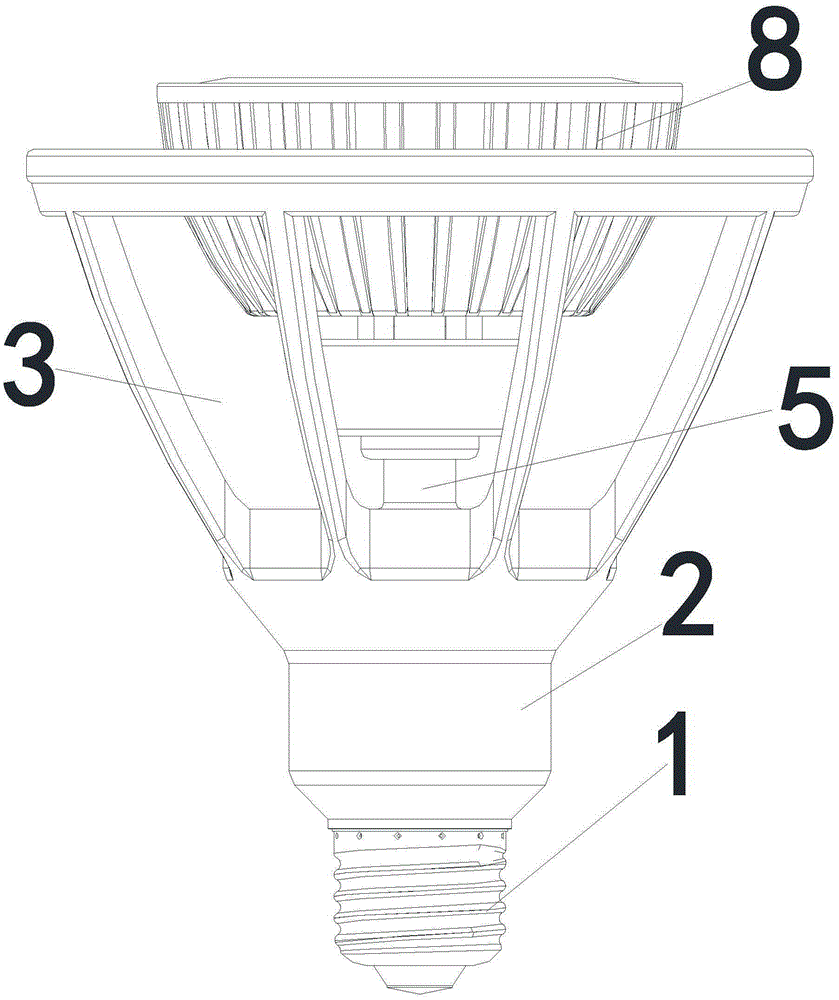

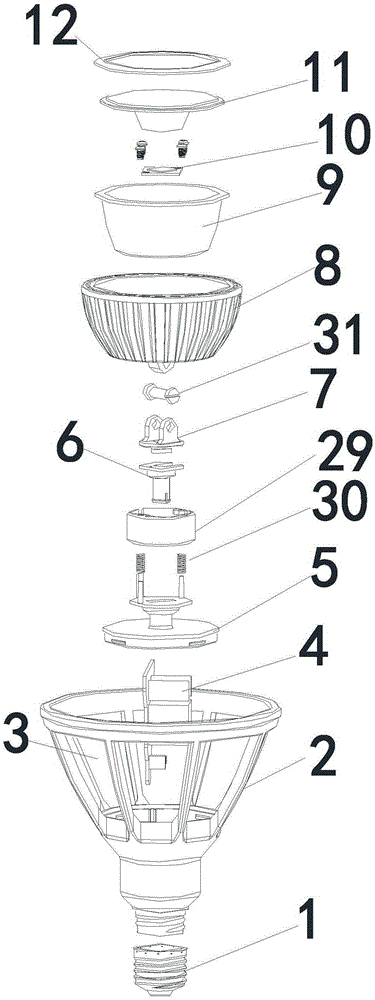

[0048] Such as Figure 1~4 As shown in 7-8, a rotary LED spotlight includes a lamp base 1, the upper end of the lamp base 1 is connected to an insulating shell 2, and a plurality of ventilation slots 3 are arranged on the insulating shell 2, and the ventilation slots 3 are arranged in a large area, and the ventilation slots 3 are convectively arranged. , the drive circuit board 4 is arranged in the insulating shell 2, the inner side of the insulating shell 2 is connected with the connecting column 5, the top of the connecting column 5 is connected with the fixed disk 6, the fixed disk 6 is connected with the rotating disk 7 whose axial rotation angle is 360°, and the rotating disk 7. The top and the heat dissipation shell 8 are movable connections with the central axis rotating at a certain angle. The heat dissipation shell 8 is provided with a reflector 9 and an LED light source 10. The LED light source 10 in this embodiment is mounted on an aluminum substrate.

[0049] This ...

Embodiment 2

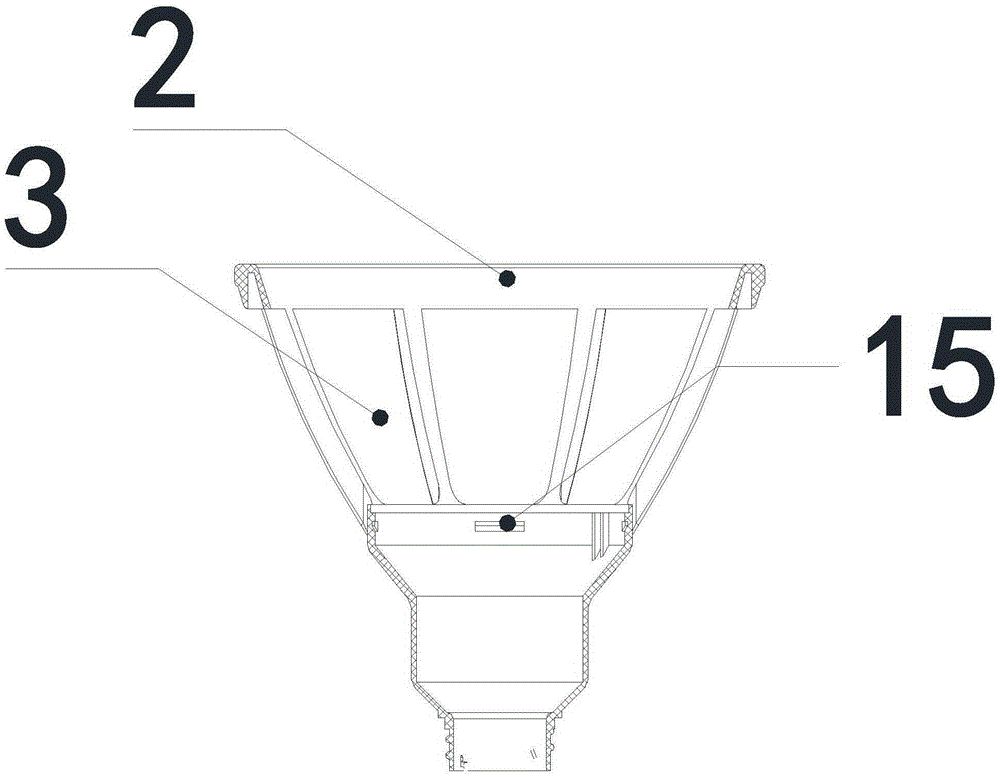

[0064] Such as Figure 5-6 As shown, the difference between this embodiment and Embodiment 1 is that: the inner surface of the second connecting column body 16 in this embodiment is provided with a connecting column clamping groove 23, and the fixed plate 6 includes a cylindrical first body 17 of the fixed plate. The lower end of the fixed disk first body 17 is provided with a fixed disk buckle 24, and the fixed disk buckle 24 is snapped into the connecting post slot 23, and the upper end of the cylindrical fixed disk first body 17 is provided with a cylindrical fixed disk second body. A notch 18 is provided on the second body of the cylindrical fixed disk, and a positioning bump 25 is arranged on the second body of the cylindrical fixed disk.

[0065] The rotating disc 7 in this embodiment includes a boss 19, a rotating disc plate 20 and a fixed bracket 21; wherein, the lower surface of the rotating disc plate 20 is provided with a boss 19, and the upper surface of the rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com