High pressure and low pressure bypass system

A technology of bypass system and high-pressure bypass, which is applied to steam engine devices, machines/engines, mechanical equipment, etc., and can solve problems such as increased cost, short service life, and uncompact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

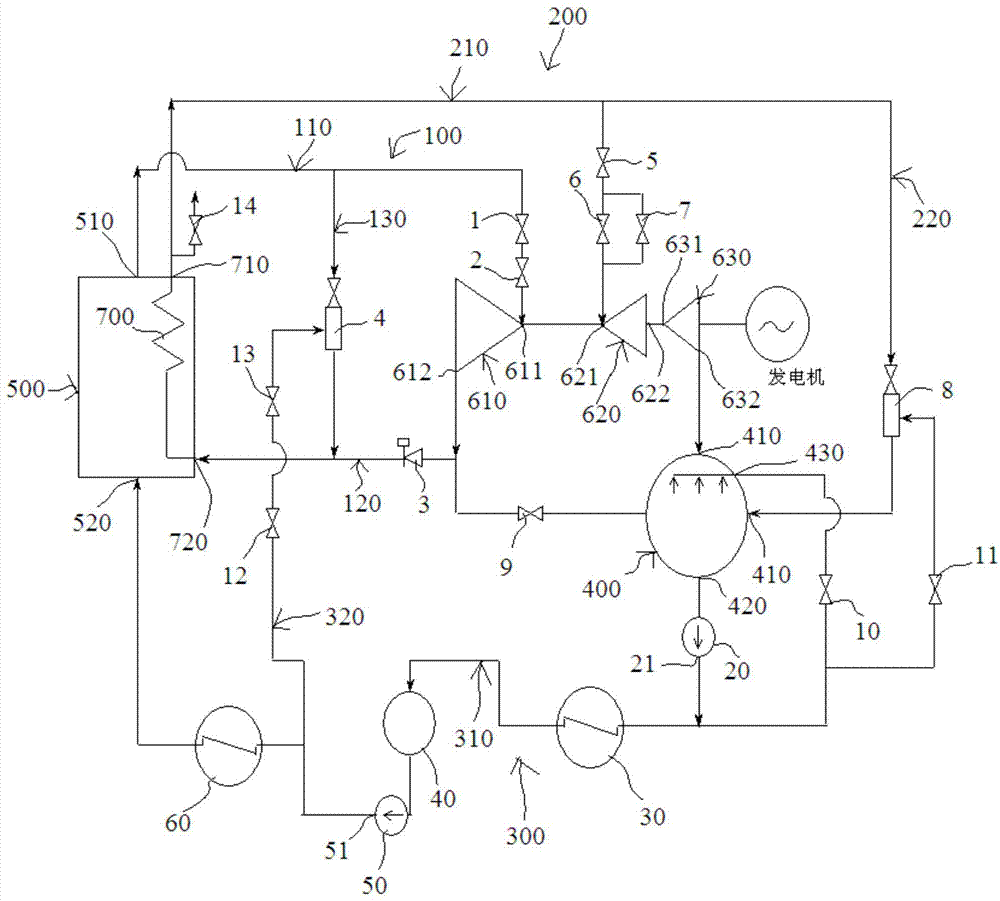

[0025] see figure 1 The high and low pressure bypass system shown includes a high pressure bypass system 100 , a low pressure bypass system 200 , a circulation pipeline 300 and a condenser 400 . The high-pressure bypass system 100 includes a superheating pipeline 110, a reheating pipeline 120, and a high-pressure bypass pipeline 130. The two ends of the superheating pipeline 110 are respectively connected to the steam output end 510 of the boiler 500 and the steam inlet end 611 of the high-pressure cylinder 610. A high-pressure main steam valve 1 and a high-pressure regulating valve 2 are sequentially arranged on the superheating pipeline 110 along the steam advancing direction. The two ends of the heat recovery pipeline 120 are respectively co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com