Design method for increasing progressive collapse resistance of RC frame structure

A design method and frame structure technology, applied in the direction of building structure, construction, etc., can solve the problem of not being able to directly reflect the consequences of progressive collapse of the structure and the ability to resist progressive collapse, and not being able to comprehensively and effectively improve the ability of the overall structural system to resist progressive collapse. Taking into account the interaction of the overall structural system and other issues, the effect of improving the structure's anti-collapse requirements is achieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

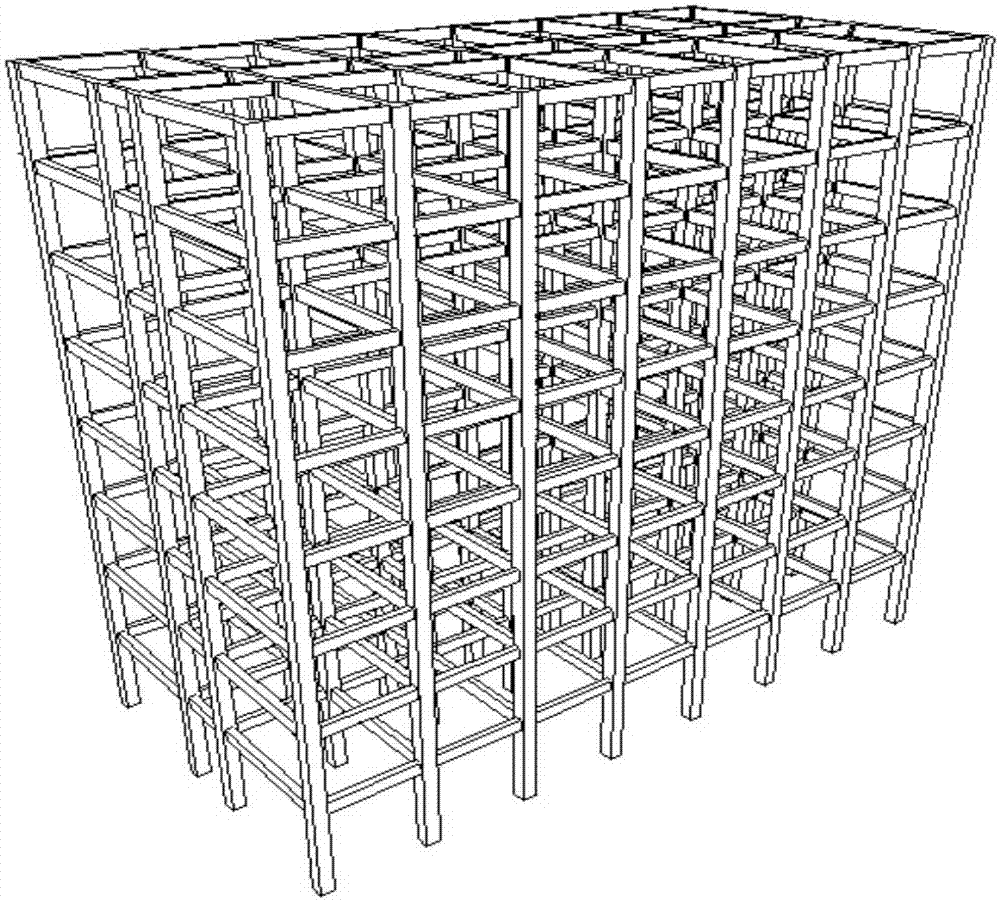

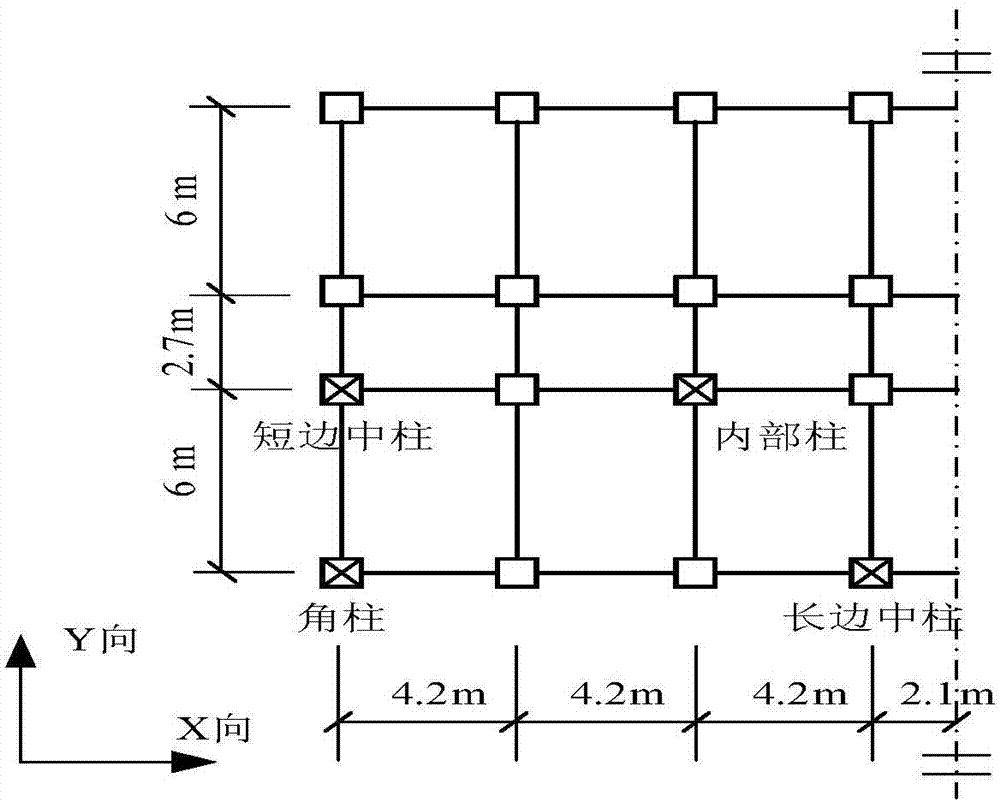

[0019] like figure 1 , figure 2 As shown, the structural mechanical response of the frame (a total of 6) after the failure of four typical partial columns on each floor was analyzed using the nonlinear dynamic demolition analysis method and the nonlinear static pushdown method, and the collapse results were obtained respectively. The results (whether progressive collapse occurs) and the anti-collapse bearing capacity curves are then analyzed based on the proposed collapse scale factor and bearing capacity safety factor, the specific implementation steps are as follows:

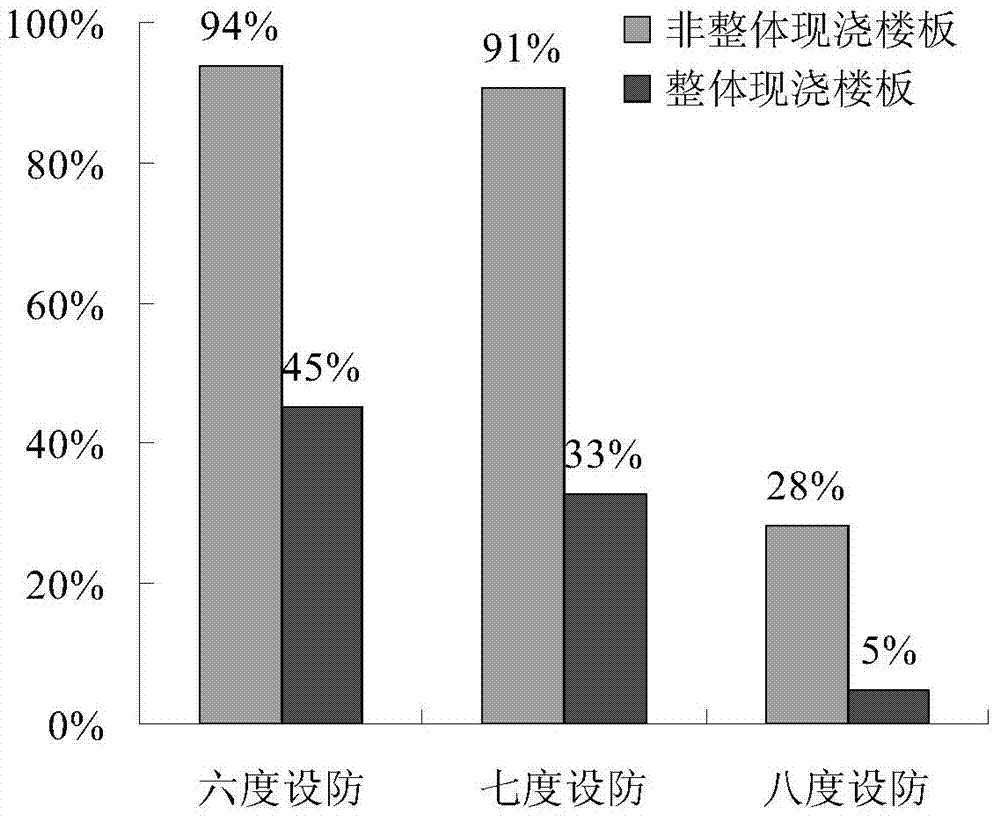

[0020] 1. Using the formula for calculating the collapse proportional coefficient without considering the initial failure probability of the component (P c =n c / n) Analyzing the results of the frame under the nonlinear dynamic demolition analysis method, the collapse ratio coefficients of non-integral cast-in-place floor frames and integral cast-in-place floor frames under three different seismic fortifica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com