Disc-shaped rotary-plate permanent magnetic coupler

A permanent magnetic coupler and turntable technology, applied in the direction of electrical components, electromechanical devices, electromechanical transmission devices, etc., can solve the problems of waste of electric energy, lack of vibration isolation and energy saving, and achieve increased coupling area, simple installation and debugging, and avoid shaft The effect of thrust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

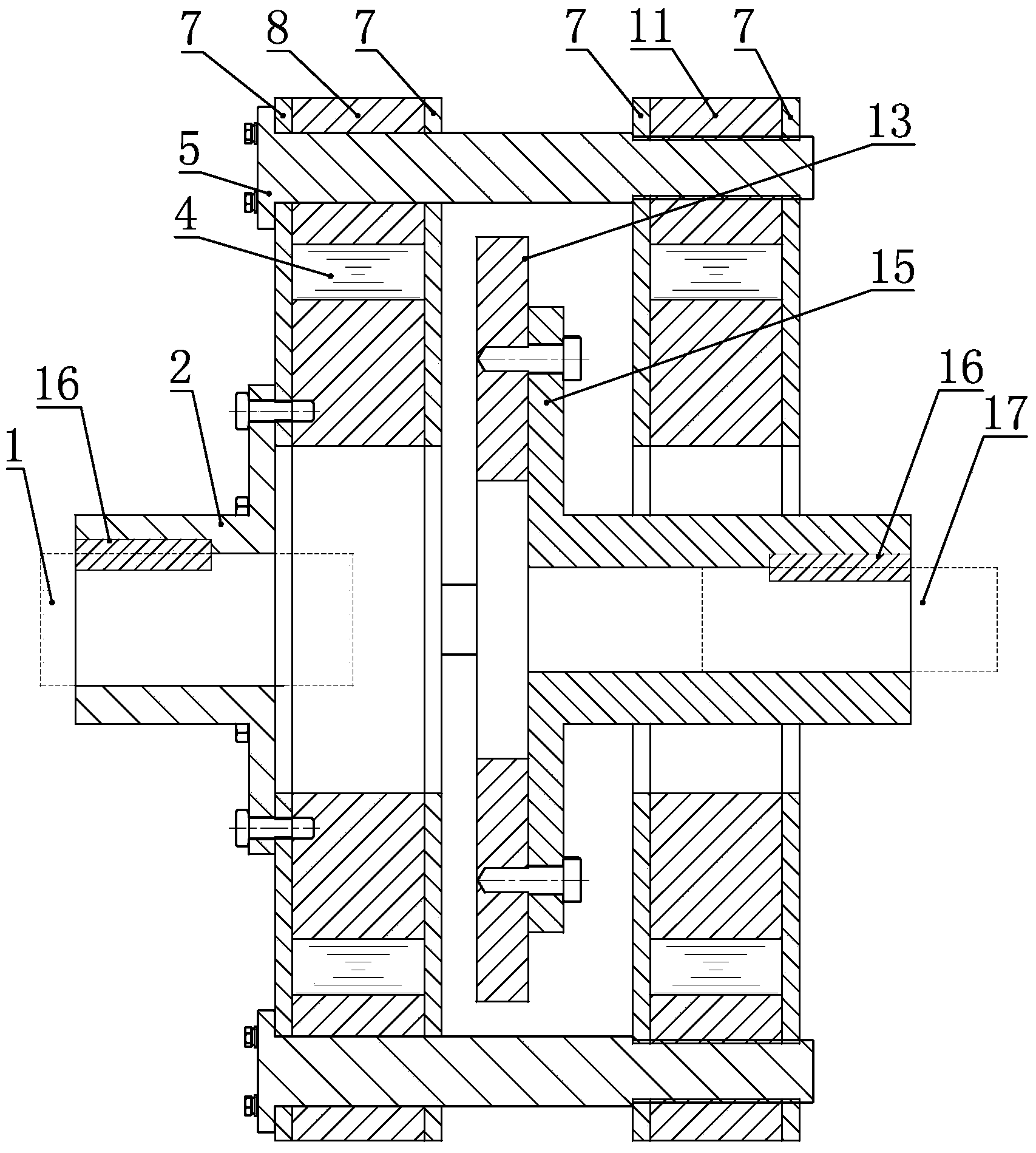

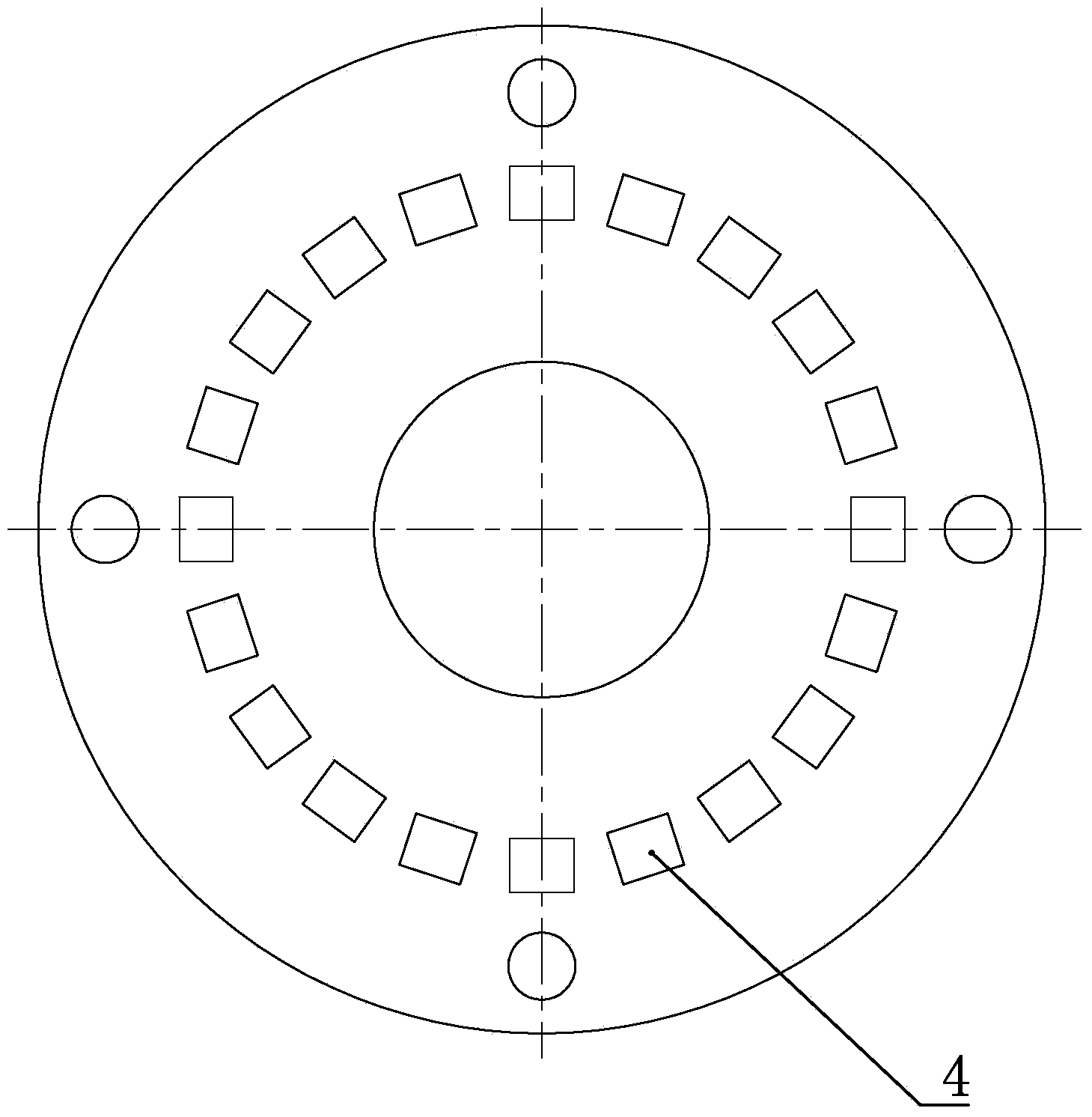

[0021] Such as figure 1 As shown, the disk-shaped turntable permanent magnetic coupler of the present invention includes a coaxial first shaft 1 and a second shaft 17, and the first shaft 1 is provided with a hub I2 and two parallel disk-type permanent magnet turntables I8 and The permanent magnet turntable II11 and the permanent magnet turntable I8 are installed on the first shaft 1 through the hub I2, and the disc-type permanent magnet turntable I8 and the permanent magnet turntable II11 are connected by a connecting rod 5, and the permanent magnet turntable I8 and the permanent magnet turntable II11 are equipped with a One or more turns of permanent magnets 4, the magnetic poles of adjacent permanent magnets 4 are installed with different poles or the same poles, and the two-layer turntables are installed opposite to each other according to the magnetic poles of the permanent magnets 4, and the magnetic pole directions are distributed along the axial direction of the permane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com