Method and device for automatically controlling heating circuits and washing machine

A technology of automatic control device and heating circuit, applied in circuit devices, emergency protection circuit devices, emergency protection devices with automatic disconnection, etc. , The effect of eliminating safety hazards and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

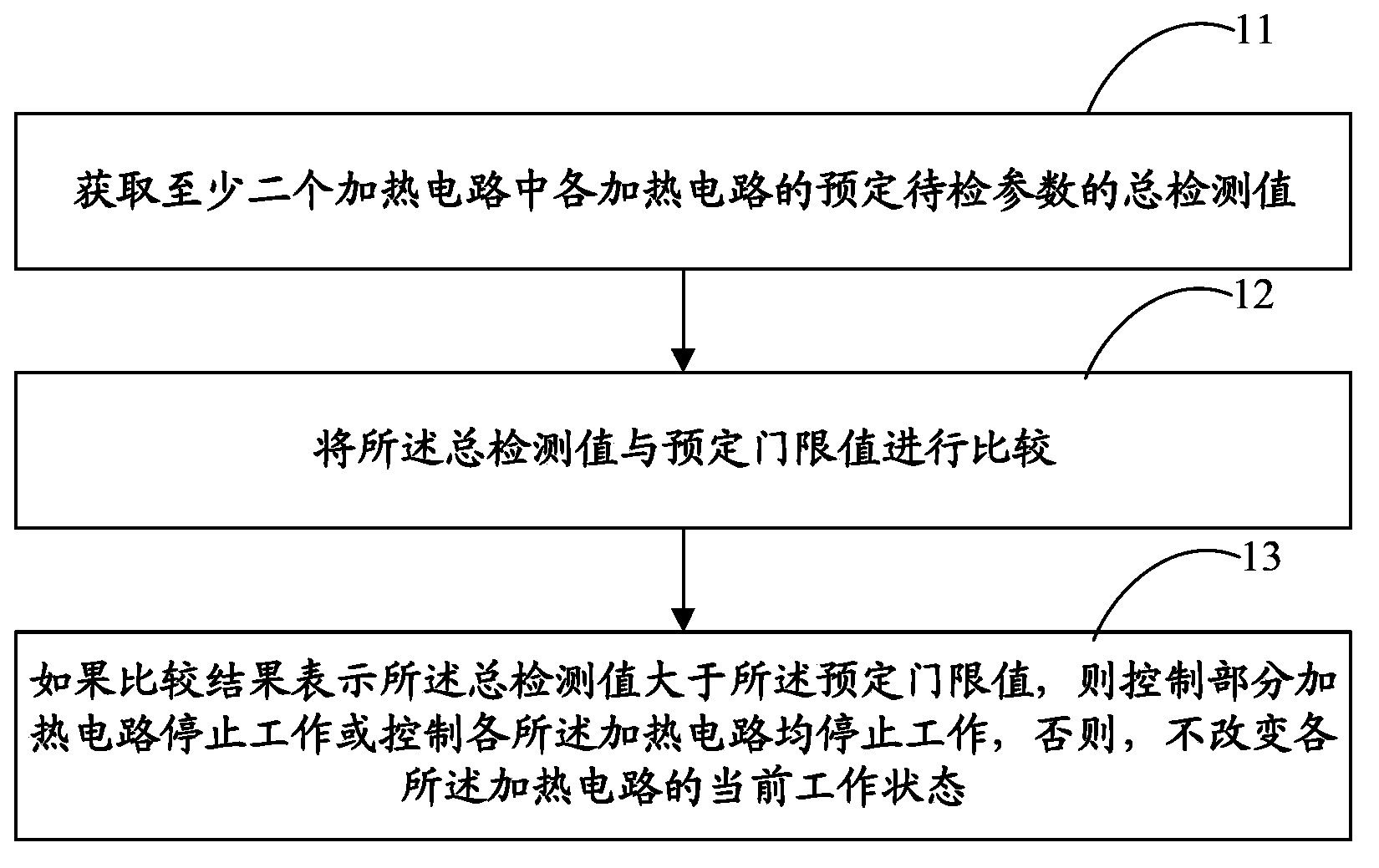

[0021] figure 1 It is a flow chart of the heating circuit automatic control method provided by Embodiment 1 of the present invention. Such as figure 1 As shown, the heating circuit automatic control method provided in this embodiment includes:

[0022] Step 11: Obtain the total detection value of the predetermined parameters to be detected in each heating circuit in at least two heating circuits.

[0023] Two or more heating circuits can be arranged in the same device, for example, two heating circuits can be arranged in a washing machine: a washing machine water heating circuit and a washing machine air-drying heating circuit. A certain predetermined parameter to be tested of each heating circuit can be detected separately to obtain the total detection value. The parameter to be detected can be determined according to actual needs. For example, the parameter to be detected can be current, and the current of each heating circuit of the device can be detected separately to o...

Embodiment 2

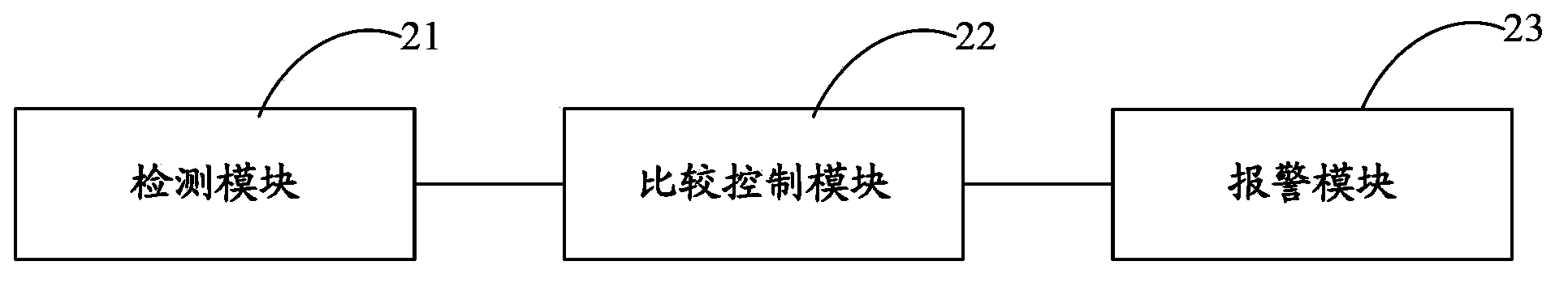

[0031] figure 2 It is a schematic diagram of an optional structure of the heating circuit automatic control device provided in Embodiment 2 of the present invention. Such as figure 2 As shown, the heating circuit automatic control device provided in this embodiment includes: a detection module 21 and a comparison control module 22 .

[0032] The detection module 21 is used to obtain the total detection value of the predetermined parameters to be detected in each heating circuit in at least two heating circuits. Optionally, two or more heating circuits can be set in the same device, for example, two heating circuits can be set in the washing machine: a washing machine water heating circuit and a washing machine air drying heating circuit. A certain predetermined parameter to be tested of each heating circuit can be detected separately to obtain the total detection value. The parameter to be detected can be determined according to actual needs. For example, the parameter to...

Embodiment 3

[0038] The present invention also provides a washing machine. The washing machine includes at least two heating circuits, and also includes any one of the above-mentioned automatic control devices for the heating circuits. The automatic control device for the heating circuits automatically controls each heating circuit, thus avoiding the The complete machine of the washing machine is damaged due to excessive load, which eliminates potential safety hazards.

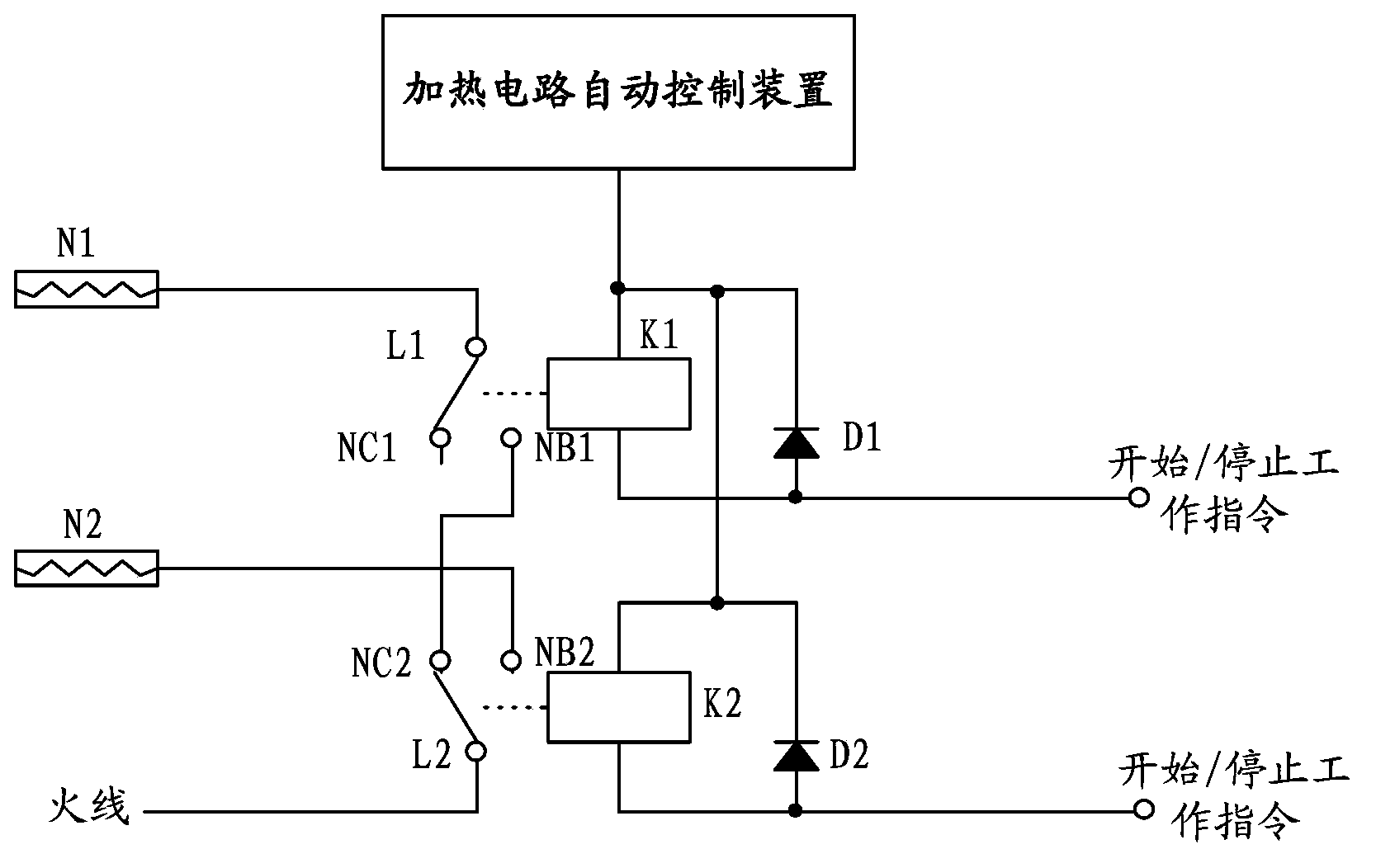

[0039] Optionally, the washing machine includes two heating circuits: a first heating circuit and a second heating circuit. Such as image 3 As shown, the first heating circuit includes: a first relay and a first heater N1, the first relay includes a first relay body (including a first relay power coil K1 and a first diode D1), the The first relay main body K1 is provided with a first incoming terminal L1, a first normally closed terminal NC1 and a first normally open terminal NB1. The second heating circuit includes: a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com