A model test device for underground engineering excavation with expansion and contraction function

A model test device and underground engineering technology, applied in teaching models, educational tools, instruments, etc., can solve the problems of soil collapse around excavated tunnels, complex underground engineering structures, constraints, etc., to achieve easy popularization and application, and good accuracy , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

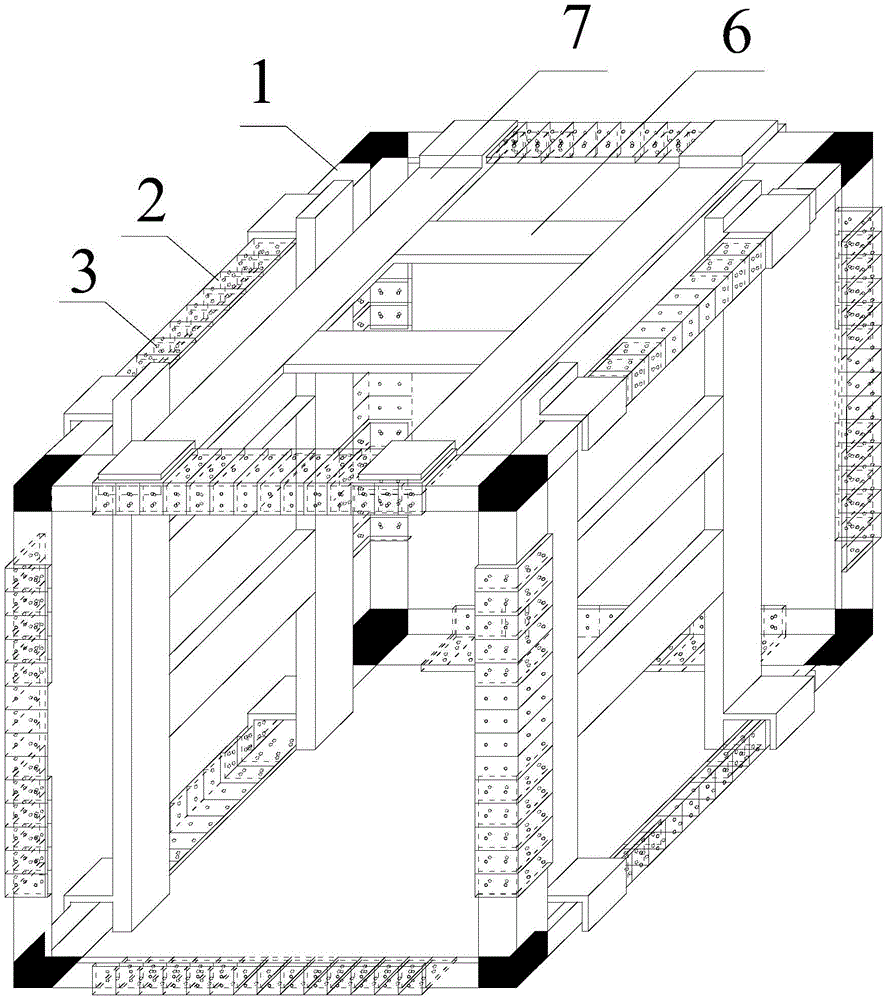

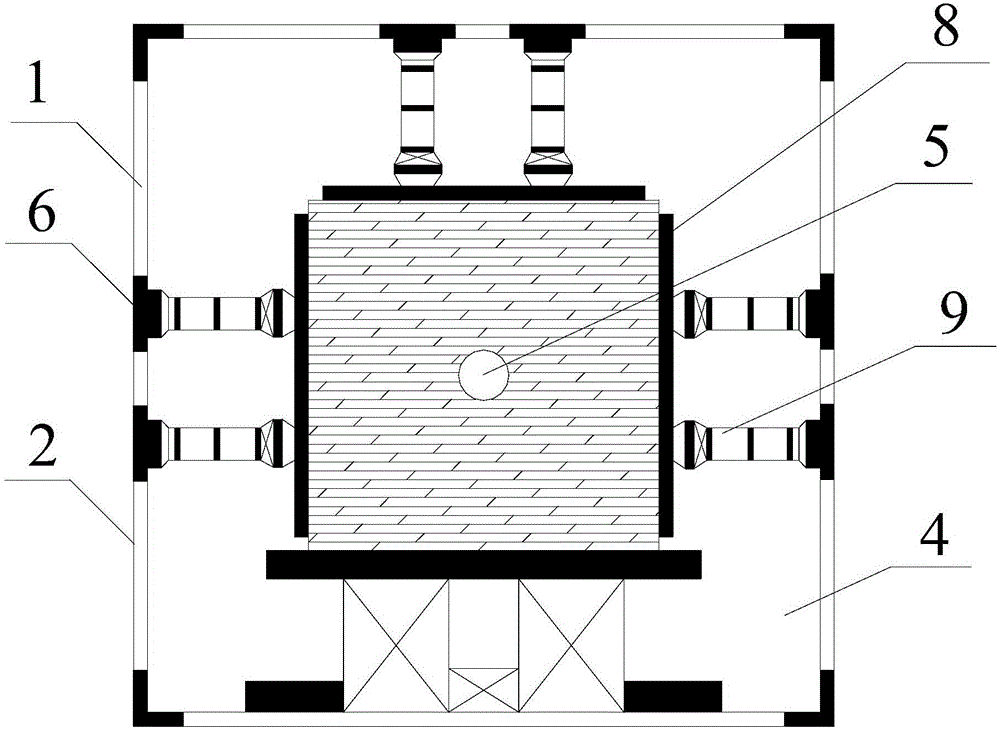

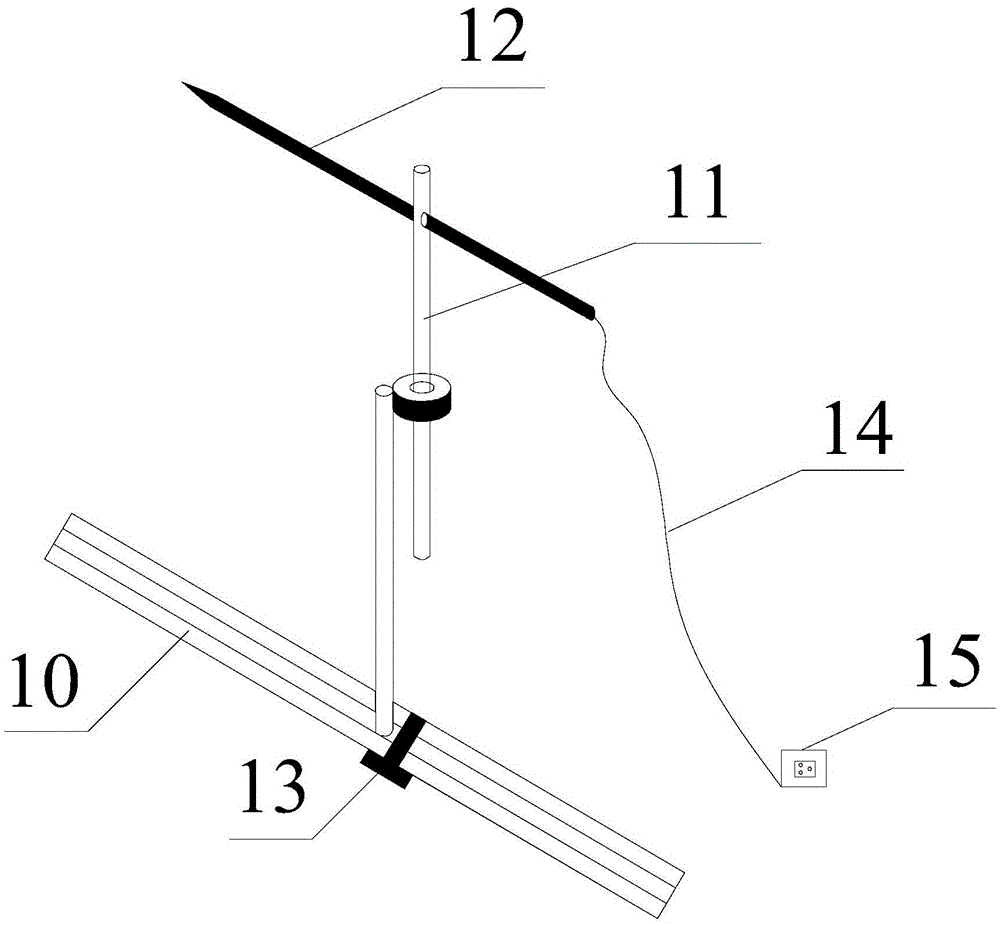

[0022] An underground engineering excavation model test device with expansion and contraction function, comprising a model test sample, a tunnel structure model 5, a loading device and an excavation device, the test device also includes a loading steel frame, and the loading steel frame is made of high-strength Angle steel 1, high-strength connecting plate 2, high-strength bolt 3, and plexiglass plate 4 are assembled. Due to the connection of each node of the steel frame and the expansion and contraction function of the high-strength angle steel 1, the model test sample is placed inside the loaded steel frame; the tunnel structure model 5 is located in the middle of the model test sample; The force beam 6, the steel plate 7, the force component steel plate 8 and the hydraulic jack 9 are composed, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com