Manual gearshift mechanism and gear recognition device

A technology of shifting mechanism and identification device, applied in transmission control, mechanical equipment, components with teeth, etc., can solve the problems of high engine speed and affect the service life of the engine, and achieve the effect of prolonging the service life and reducing fuel consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

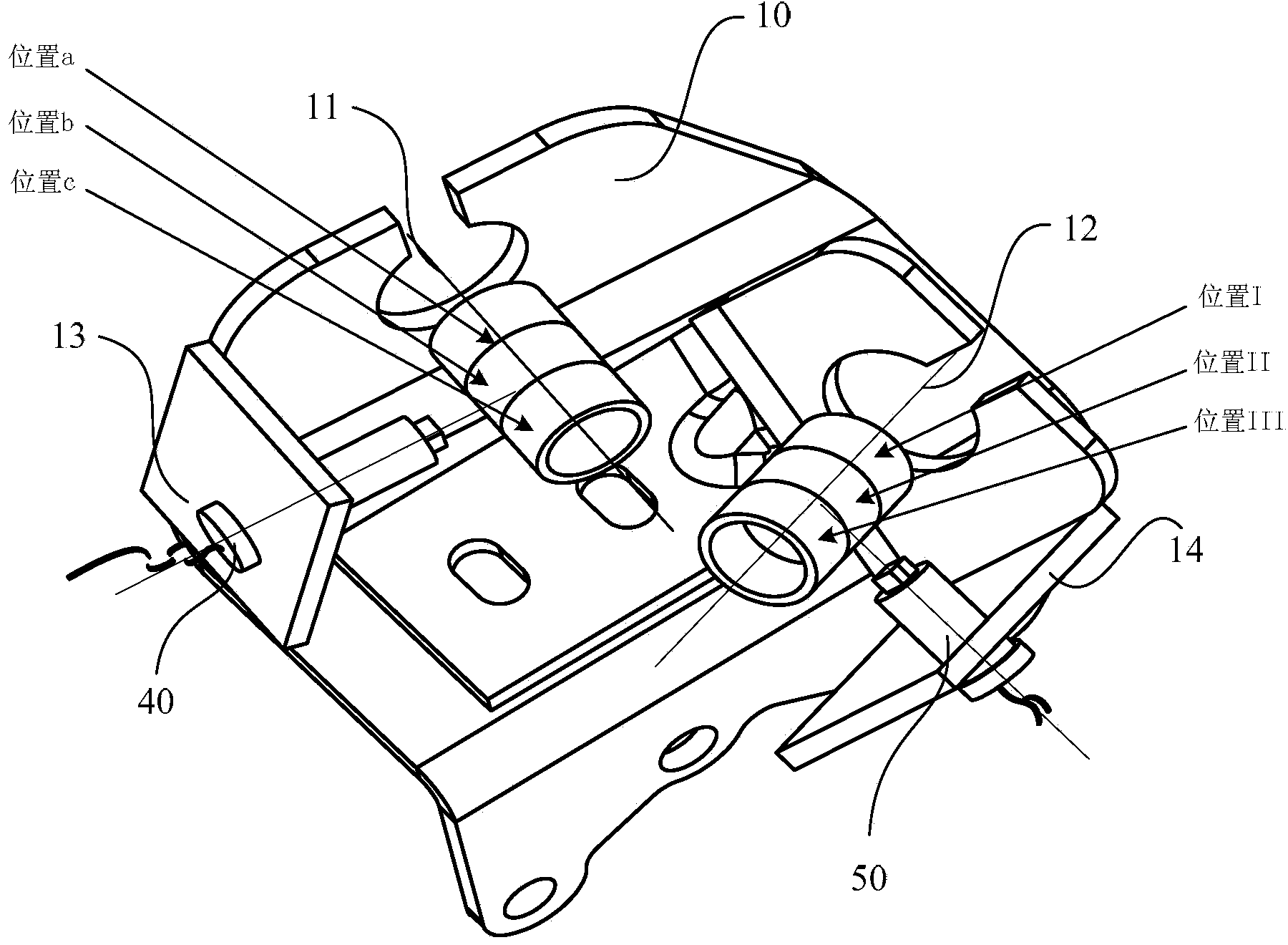

[0031] In order to further illustrate the gear recognition device and the manual gear shift mechanism provided by the embodiments of the present invention, a detailed description will be given below in conjunction with the accompanying drawings.

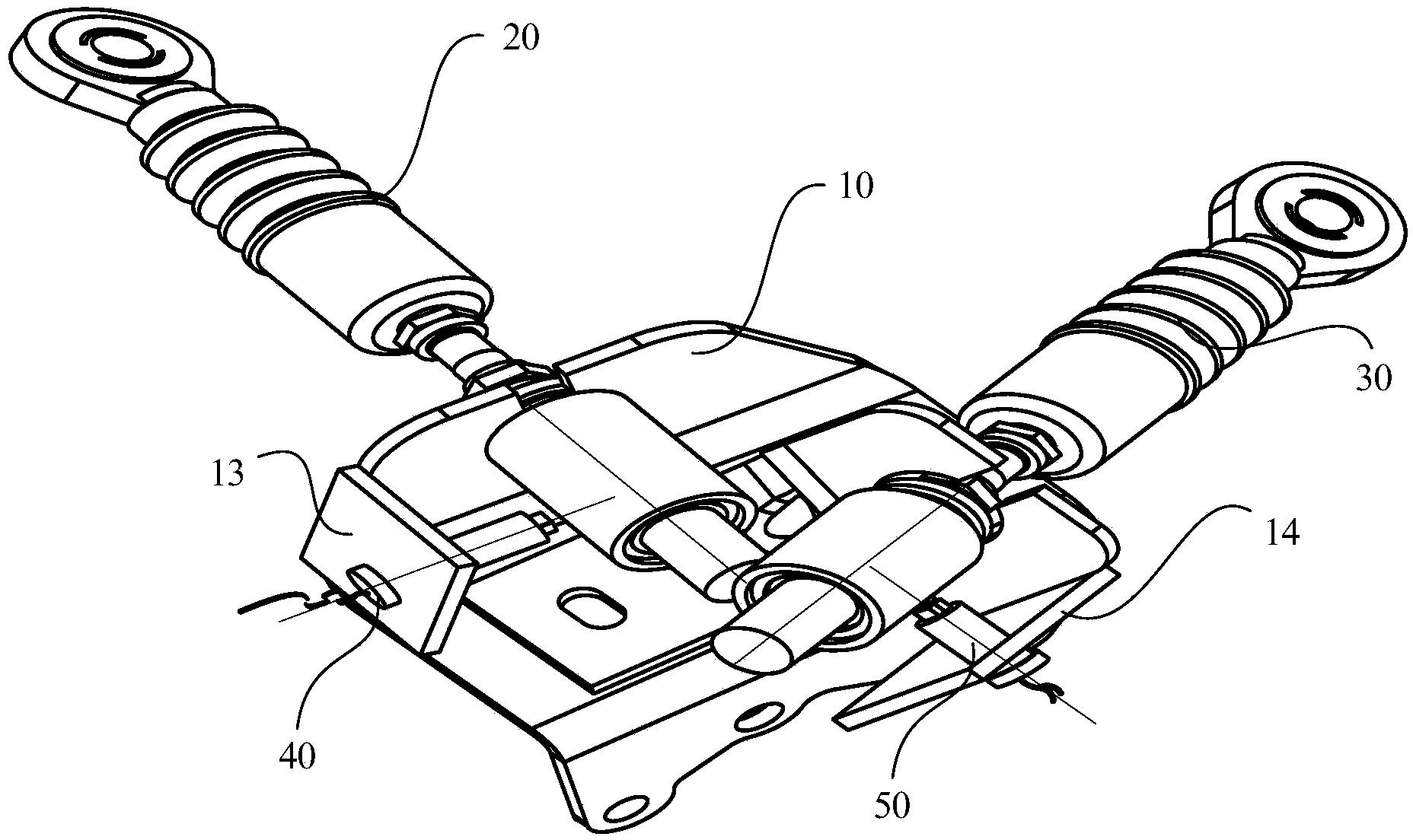

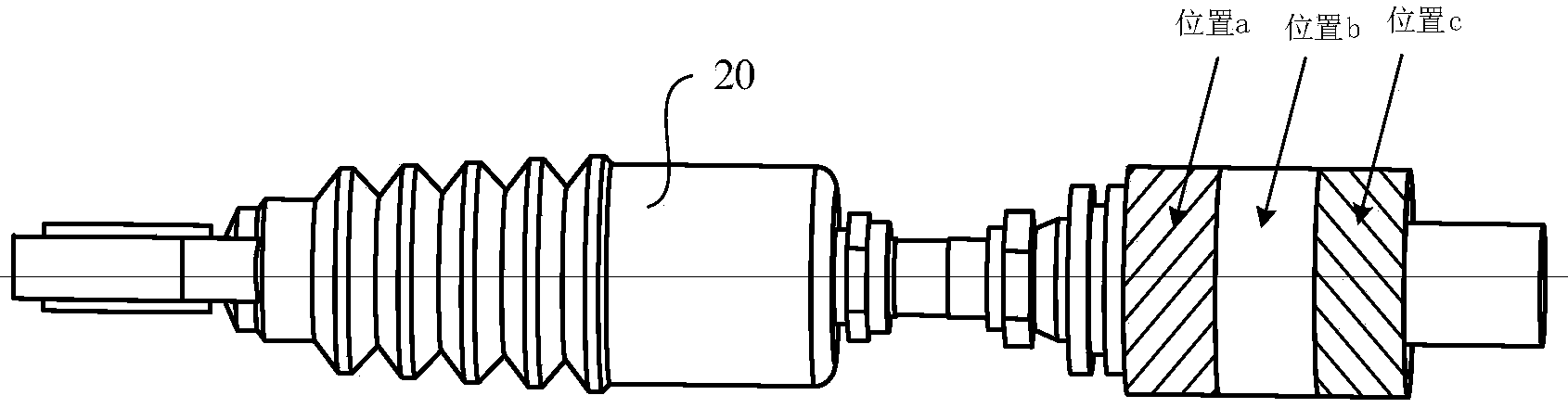

[0032] see figure 1 , figure 2 with image 3 , the manual shift mechanism provided by the embodiment of the present invention includes: a shift handle, a shift flexible shaft 20 connected to the shift handle at one end and connected to the shift rocker arm at the other end, connected to the shift handle at one end, and connected to the selector at the other end. The gear selection flexible shaft 30 connected to the gear rocker arm, and the gear recognition device located outside the transmission housing, wherein the gear recognition device includes:

[0033] A zipper bracket 10 fixedly installed on the transmission housing, the zipper bracket 10 has a shift flexible shaft hole 11 for the shift flexible shaft 20 to pass through and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com