Shield electric pump for conveying media easy to solidify and crystallize

A technology for shielding electric pumps and media. It is used in pumps for special fluids, components of pumping devices for elastic fluids, pumps, etc., and can solve problems such as low freezing point, blockage, and easy solidification or crystallization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below according to the drawings and embodiments.

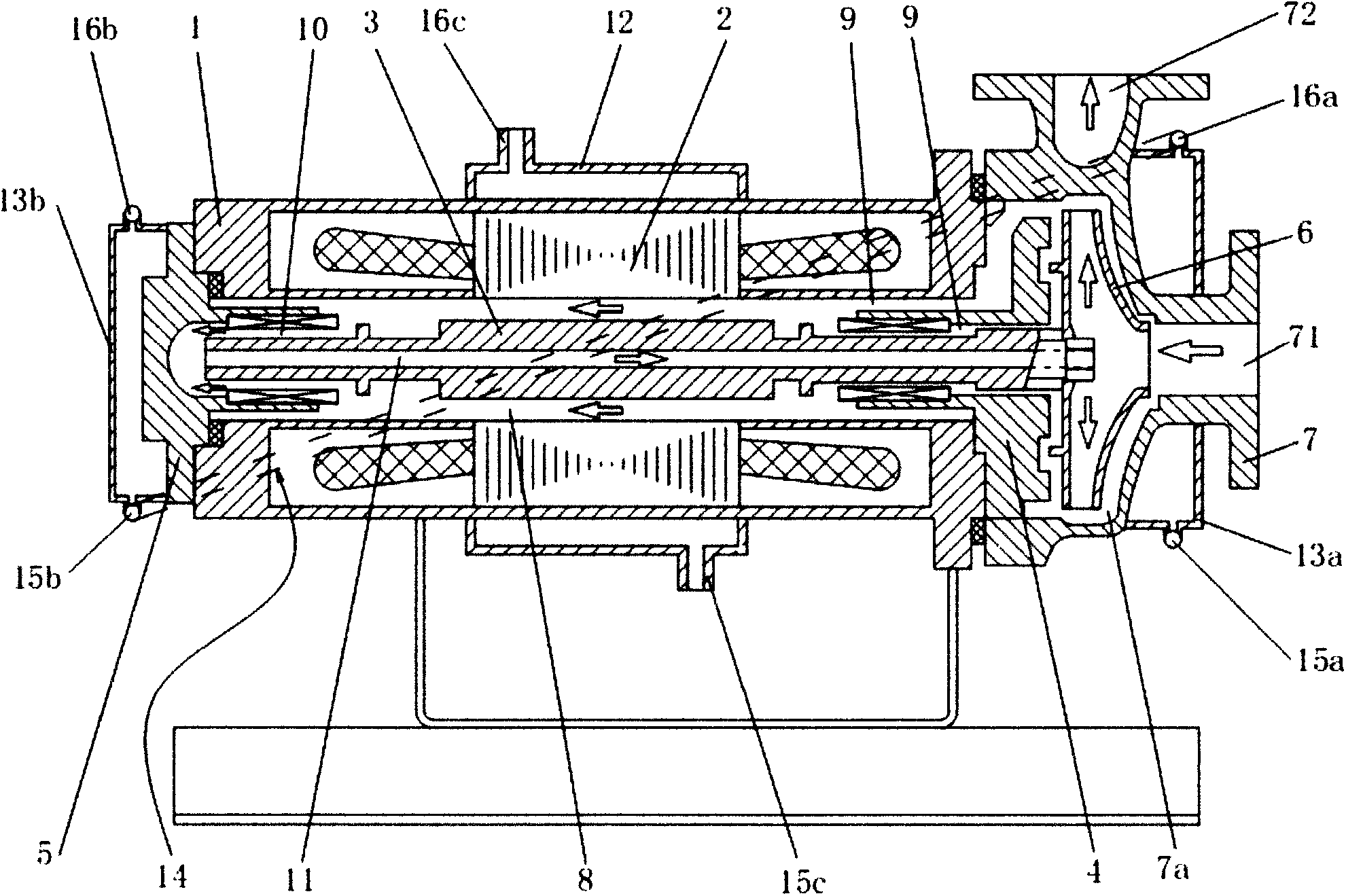

[0015] Such as figure 1 As shown, the shielded electric pump for transporting easily solidified and crystalline media according to the embodiment of the present invention includes a casing 1, a stator 2 and a rotor 3, and the rotor 3 passes through the front bearing housing 4 and the rear bearing arranged at both ends of the casing 1. The seat 5 is installed, the stator 2 is coaxially sleeved in the casing 1, the rotor 3 protrudes out of the front bearing seat 4 and is fixedly connected with the impeller 6, and the impeller 6 is covered with a pump body 7 sealed and fixed with the casing 1. The side end of the pump body 7 is provided with a feed port 71 communicated with the pump chamber 7a, the upper end of the pump body 7 is provided with a discharge port 72 communicated with the pump chamber 7a, an air gap channel 8 is provided between the stator 2 and the rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com