Novel outer wall joint straightness ensuring device and use method thereof

A new type of exterior wall technology, which is applied to the joints of formwork/formwork/work frame, formwork/formwork/work frame, and on-site preparation of building components. Problems such as mold expansion and strength cannot be guaranteed, so as to achieve the effect of saving materials, ensuring construction speed, and smooth and straight joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

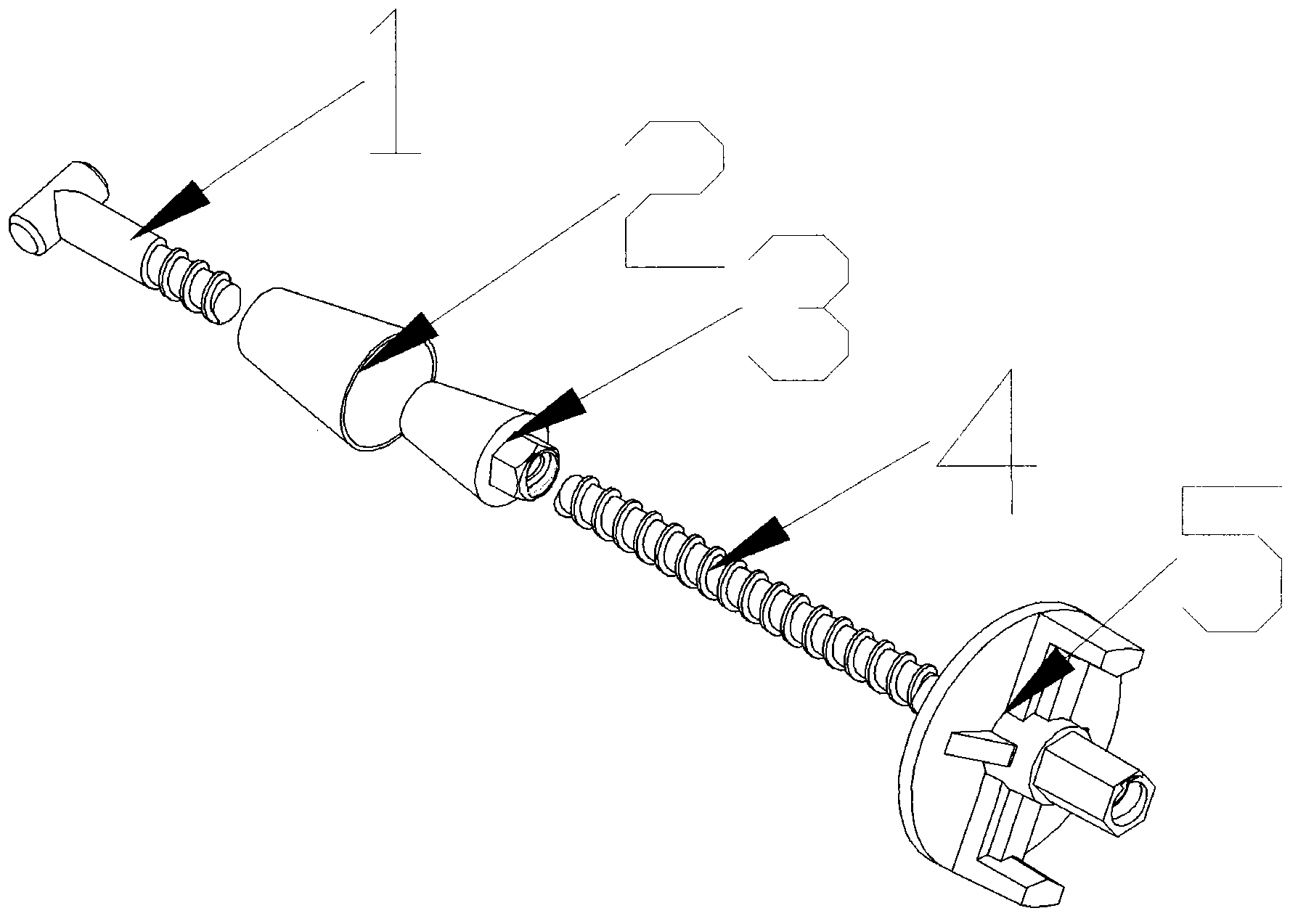

[0012] figure 1 Among them, a new type of device for ensuring the straightness of the outer wall joints is composed of a positioning screw 1, a plastic sleeve (2), a positioning cone 3, an opposite pull screw 4 and a mountain nut 5, wherein the positioning cone 3 connects the positioning screw 1 and the opposite The pulling screw rod 4 is connected, the plastic sleeve 2 is tightly sleeved on the outside of the vertebral body 3, the mountain nut 5 is connected with the pulling screw rod 4, and is connected into a straight line.

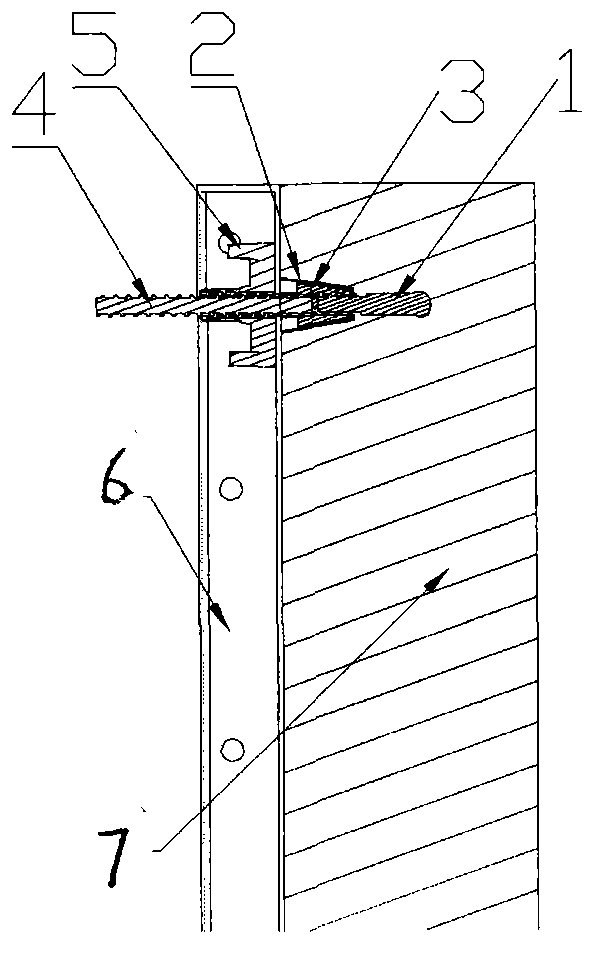

[0013] figure 2 Among them, before pouring the concrete, the positioning screw 1, the plastic sleeve 2, and the positioning cone 3 are fixed on the formwork by the pull screw 4 and the mountain nut 5. Among the figures, 6 is the exterior wall formwork, and 7 is uncast concrete.

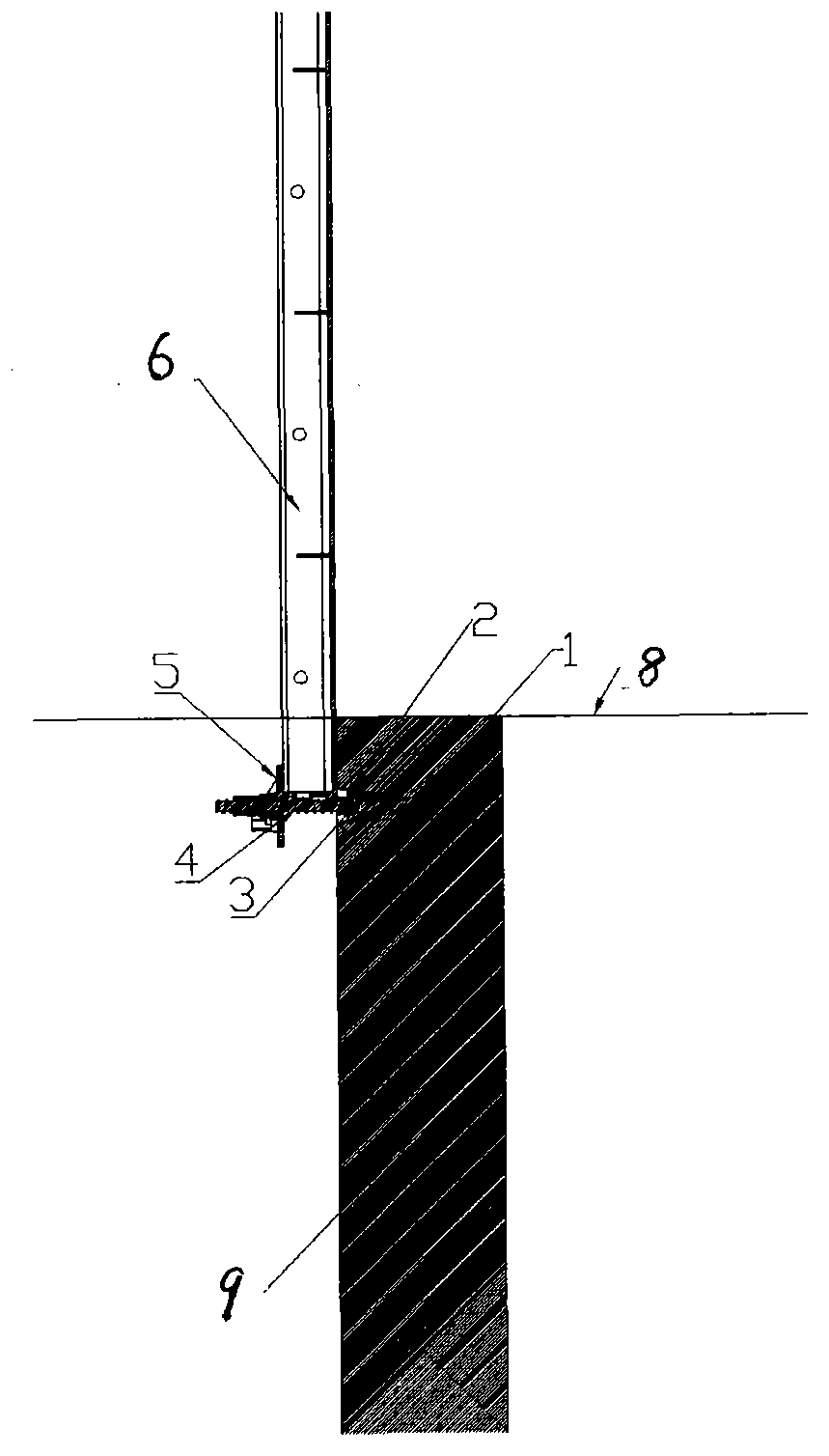

[0014] image 3 When entering the construction of the upper floor, the exterior wall formwork can be directly placed on the tension screw rods 4 at a certain distance, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com