A glass fiber fiberizing machine

A glass fiber and fiberizing machine technology, which is applied in the field of glass fiber fiberizing machine and glass fiber production device, can solve the problems of unstable fiber quality, unstable transmission, large vibration, etc., to ensure stability and reliability. , to ensure stability and consistency, and to improve the effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

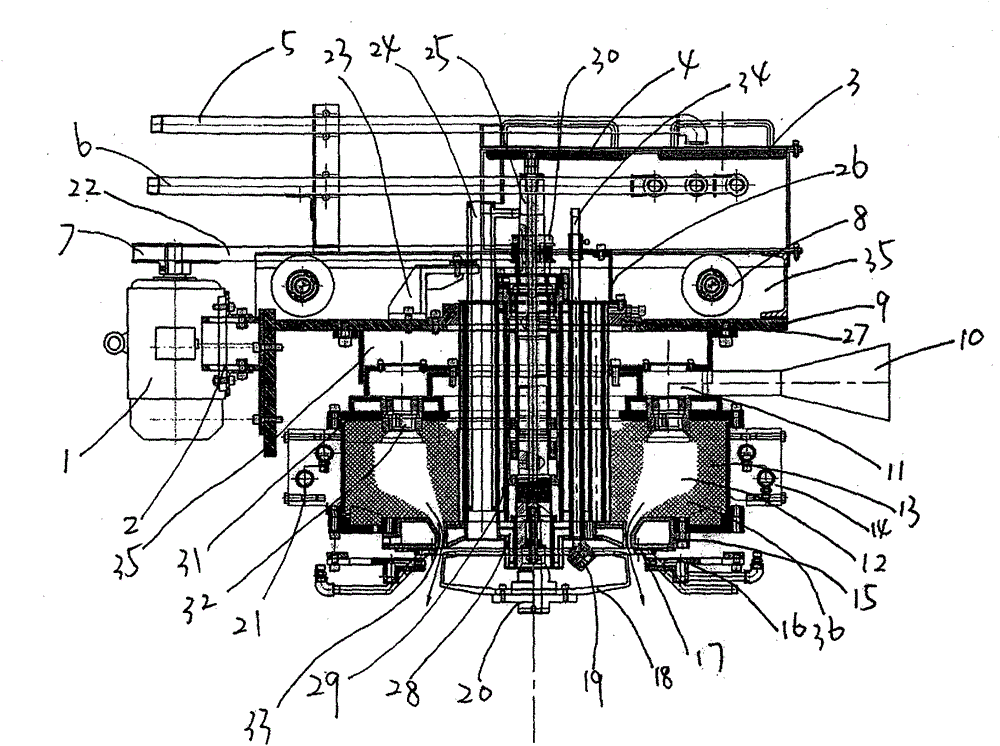

[0012] A glass fiber fibrillating machine, comprising a frame 35, a transmission device, a centrifugal device, a main combustion device and an internal combustion device, the transmission device includes a motor 1 fixed on the motor adjustment frame 2, a motor 1 fixed on the output shaft of the motor 1 Drive pulley 7 and the driven pulley 30 and drive belt 22 that are fixed on the main shaft 25, drive pulley 7 link to each other with the wheel 8 that is fixed on the frame 35, centrifugal device includes main shaft 25, the centrifuge that is fixed on main shaft 25 one ends 18. Supply liquid to the centrifuge 18 and feed the feed pipe 24 of the liquid glass raw material. The feed pipe 24 fixed on the feed pipe fixing frame 23 is connected with the frame 35 and the bottom plate 9. The main combustion device includes a gas supply channel 10, Top plate 31, be arranged on the top plate 31 and several combustion nozzles 32 that are evenly distributed along the circumferential directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com