Stacking mechanism

A technology of cushioning parts and media, which is applied in stacking receiving devices, thin material handling, transportation and packaging, etc. It can solve the problems of flipping sheet media, limited elasticity of cushioning parts, and limited impact absorption capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The stacking mechanism of the present invention will be further described in detail below with reference to the drawings and embodiments.

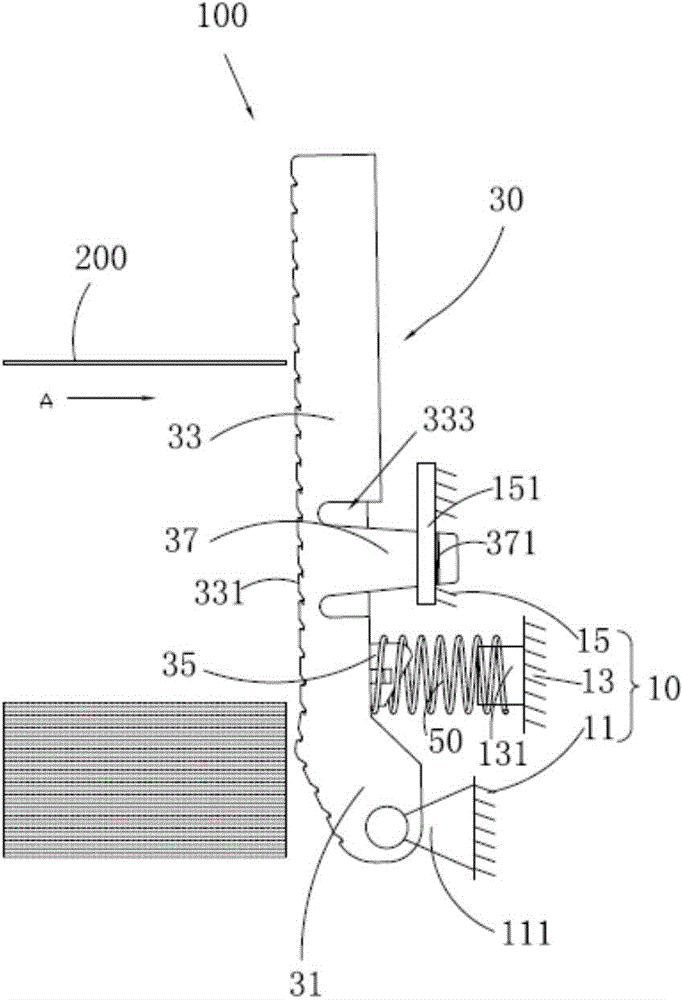

[0016] see figure 1 , the stacking mechanism 100 of the present invention is used to stack sheet media 200 , which includes a support 10 , a buffer member 30 rotatably disposed on the support 10 , and an elastic member 50 disposed between the support 10 and the buffer 30 . When the sheet medium 200 hits the buffer member 30 , the buffer member 30 can push the elastic member 50 and rotate relative to the bracket 10 to buffer the sheet medium 200 . When the sheet medium 200 is at rest, it descends to the sheet medium 200 that has fallen before under the action of its own gravity, so as to realize the stacking of the sheet medium 200 . In this embodiment, the sheet medium 200 is paper money.

[0017] The bracket 10 includes a first fulcrum 11 , a second fulcrum 13 , and a third fulcrum 15 arranged at intervals in sequence. The secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com