Method and device for producing green purified rice and device

A rice and green technology, which is applied in the direction of gas-containing food ingredients and food ingredients as antimicrobial preservation, food preservation, etc., can solve the problems of environmental pollution, high pressure, and high cost of purifying rice, so as to reduce costs and improve the quality assurance period and taste effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described in further detail now in conjunction with accompanying drawing. The accompanying drawings are simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so that they only show the components relevant to the present invention.

[0020] Specific implementation one: please refer to figure 1 , a kind of production method of green purified rice, described method is the method for supercritical fluid extraction of carbon dioxide, comprises:

[0021] (1), the rice to be purified is put into the extraction kettle 4, and the pure water as the entrainer is added in the entrainer storage tank 3 simultaneously, and the weight ratio of the pure water and rice is 1: 100;

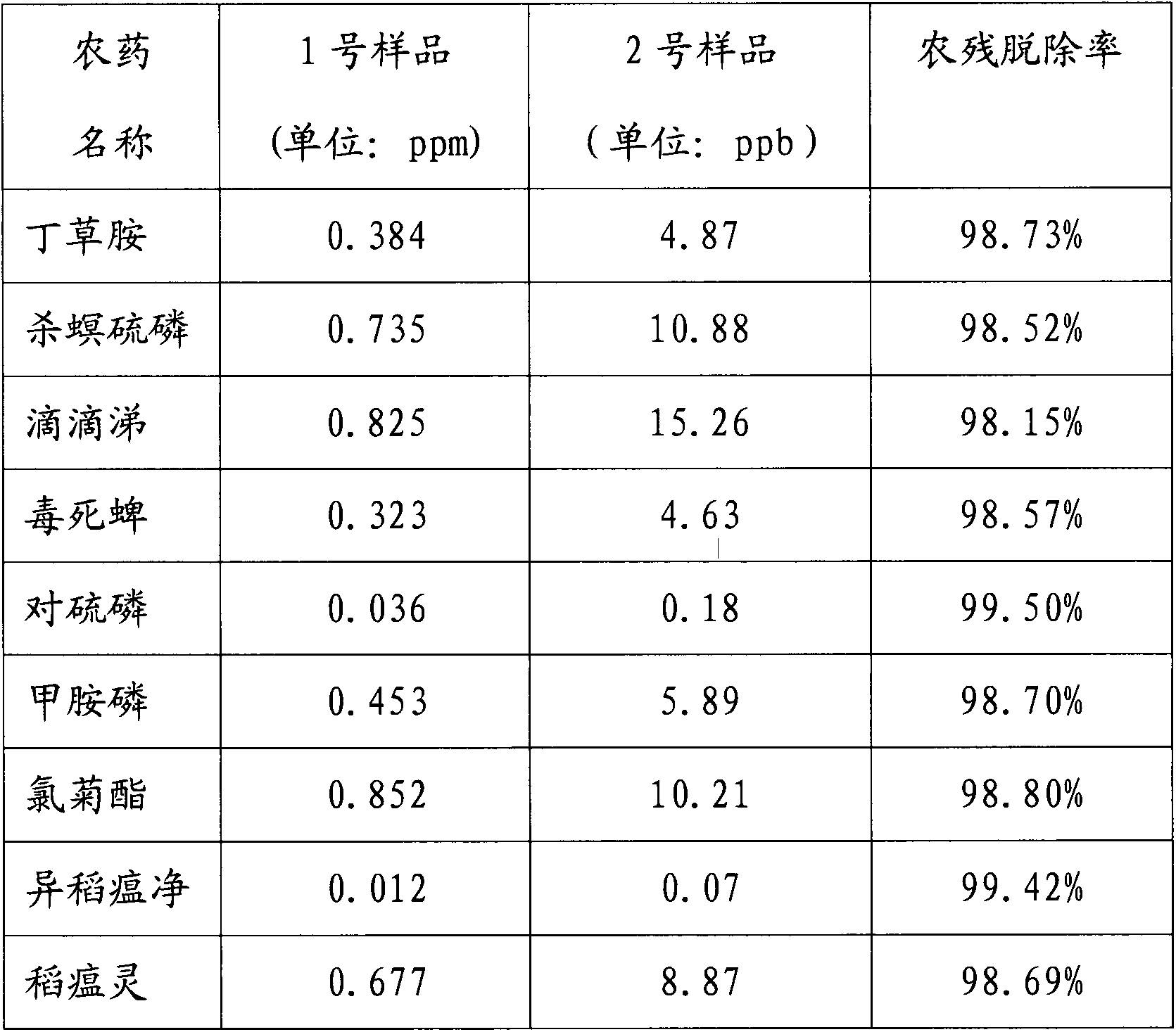

[0022] (2), the extraction conditions used are: use supercritical carbon dioxide as the extraction solvent, the extraction pressure is 7.2MPa, the extraction temperature is 25°C, the flow rate of the extraction solvent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com