Secondary sealing pipe joint and its ferrule

A secondary sealing and pipe joint technology, which is applied in the direction of sealing surface connection, pipe/pipe joint/pipe fitting, passing components, etc., can solve the problems of poor sealing reliability, achieve good sealing reliability and reduce the possibility of air leakage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

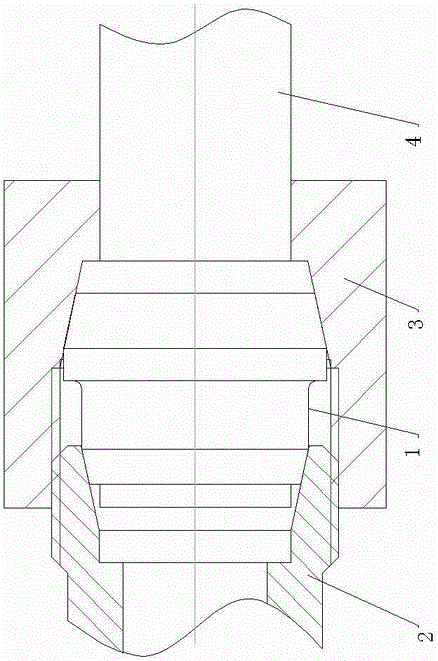

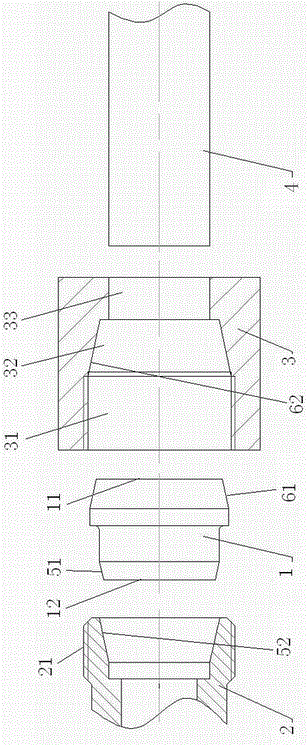

[0016] Embodiment 1 of the secondary sealing pipe joint of the present invention, such as Figure 1-4 Shown: The secondary sealing pipe joint includes ferrule 1, joint body 2 and connecting nut 3.

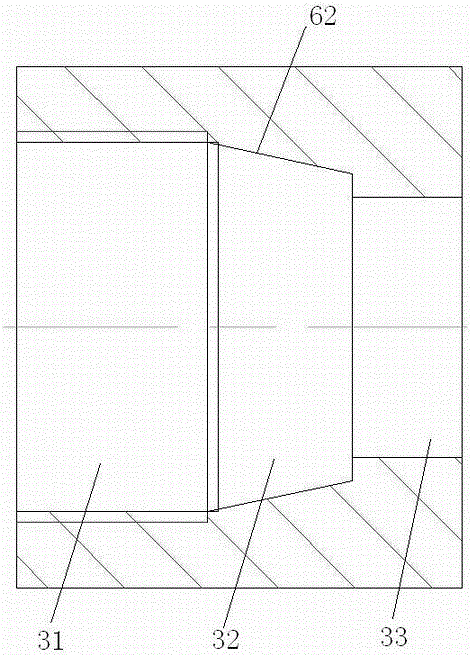

[0017] One end of the ferrule 1 is the inlet end 11 for the insertion of the pipeline 4, and the other end is the joint end 12 connected with the joint body 2. The outer circumference of the joint end 12 of the ferrule 1 is provided with a first sealing surface 51, and the joint body 2 is provided with a first sealing surface 52 that is sealingly matched with the first sealing surface 51, and the outer circumference of the inlet end 11 of the ferrule 1 is provided with a second sealing surface 61, and the connecting nut 3 is provided with a second sealing surface 61. 61 is a second sealing mating surface 62 for sealing engagement.

[0018] In this embodiment, both the first sealing surface 51 and the second sealing surface 61 are tapered surfaces. In other embodiments, the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com