Ultrahigh-pressure air compressor

An air compressor, ultra-high pressure technology, applied in the direction of mechanical equipment, machines/engines, liquid variable capacity machinery, etc., can solve the problems of bulkiness and low efficiency, and achieve the solution of residual air volume, small single-stage compression ratio, fluctuations small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments according to the present invention will be described in detail below with reference to the accompanying drawings.

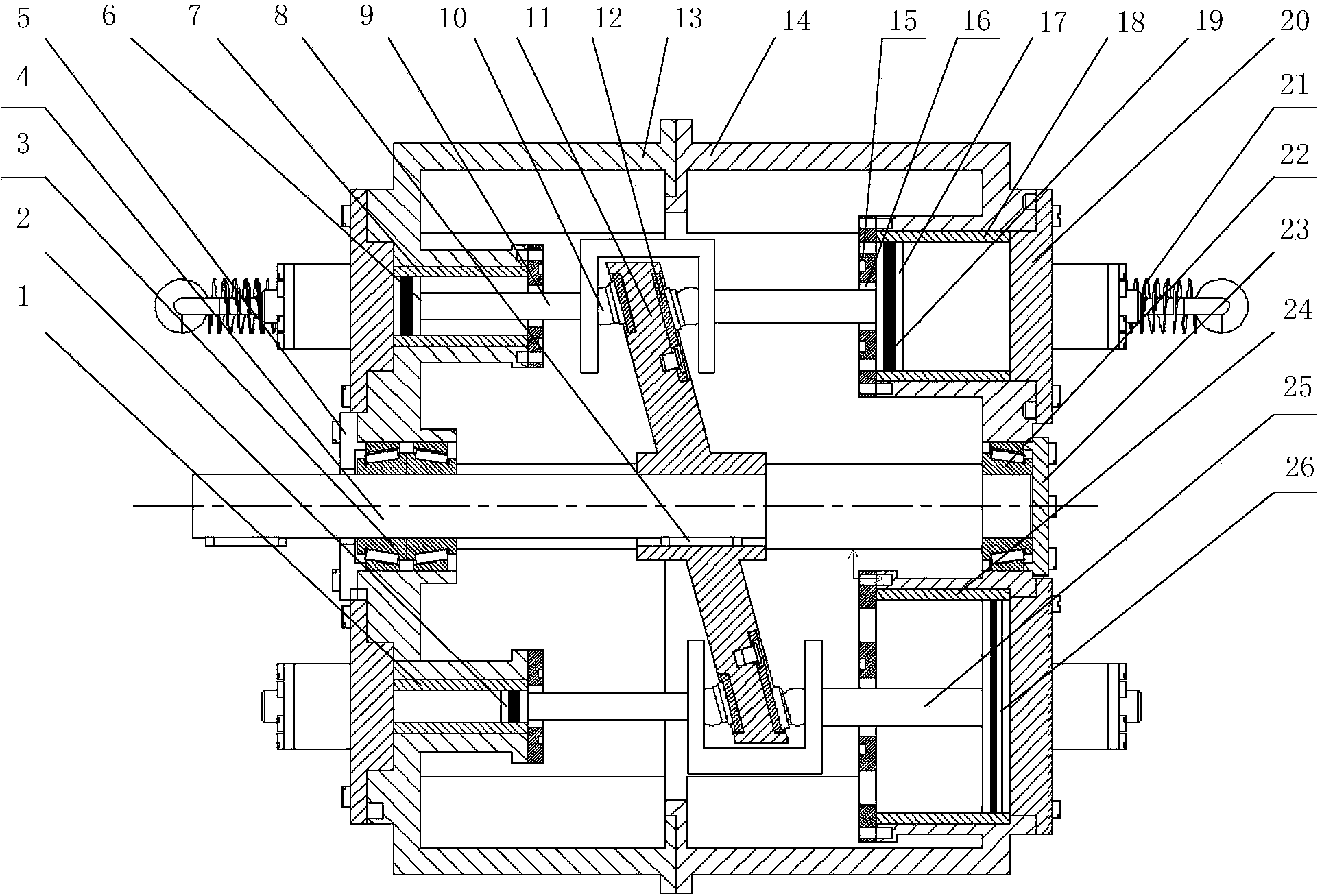

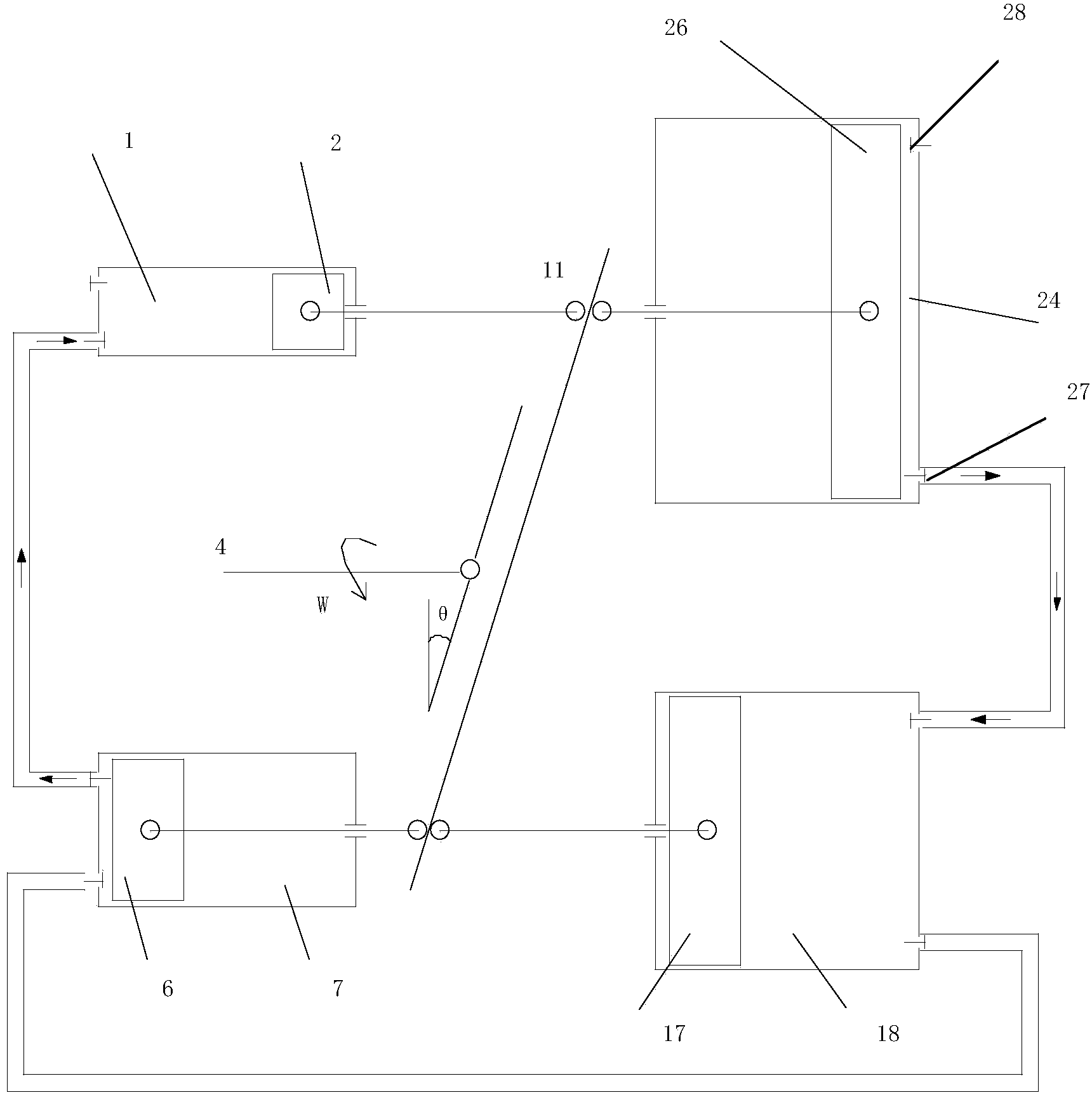

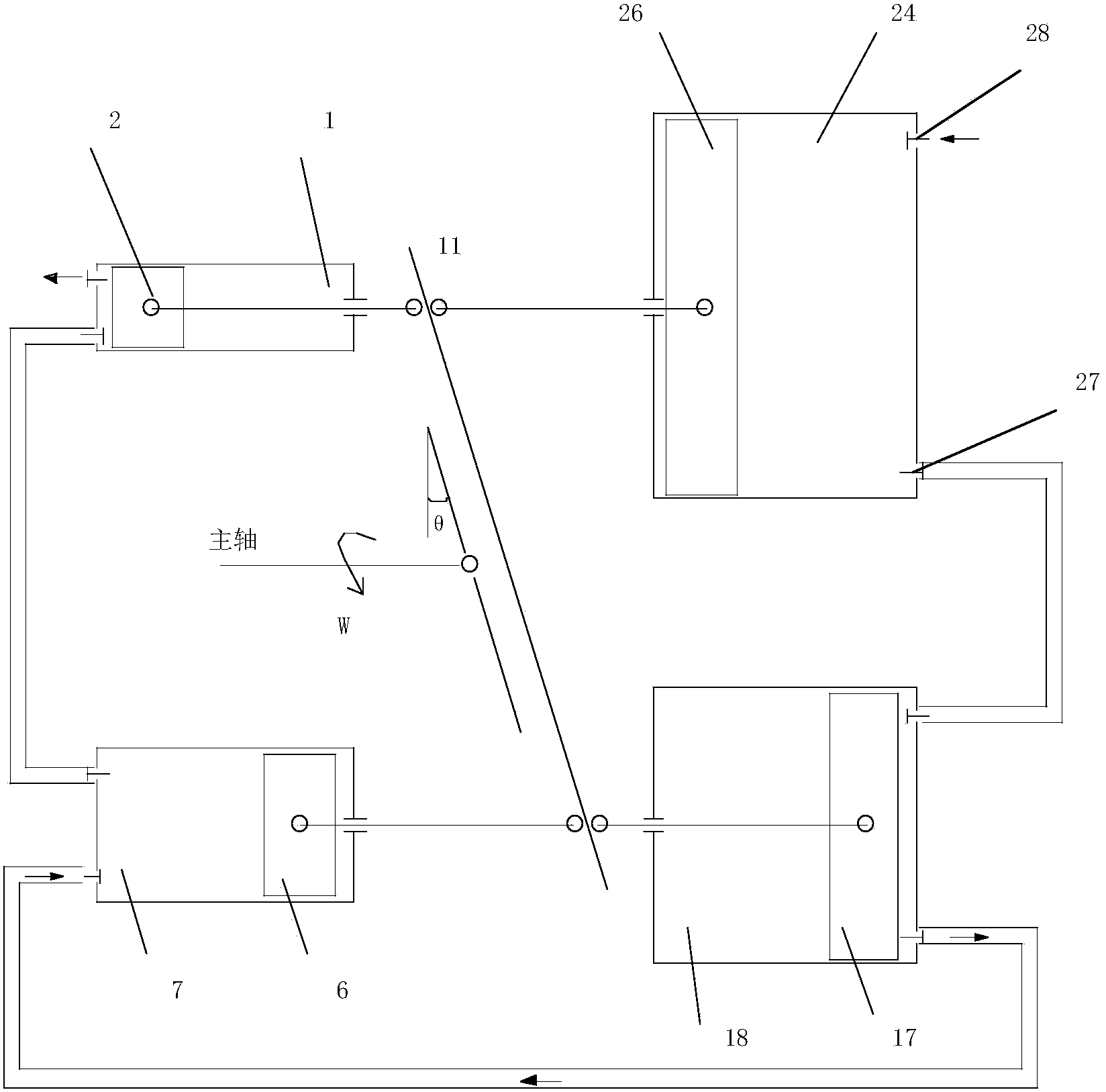

[0019] The ultra-high pressure air compressor according to the present invention includes: a plurality of cylinders and correspondingly a plurality of pistons for compressing the gas in the cylinders; a plurality of double-acting connecting rods arranged along the working direction of the cylinders, and one end is provided with the The other end of the piston is connected to the swash plate which plays a driving role, and the swash plate is used to drive the double-acting connecting rod to move along the working direction; wherein, the number of the swash plate is single, and the swash plate is in a shape relative to the working direction Arranged obliquely at an acute or obtuse angle, the multiple double-acting connecting rods and the multiple cylinders are respectively arranged in parallel on both sides of the swash plate in a symmetrical mann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com