stress release roller

A stress release and roller technology, applied in the laying of tracks, roads, tracks, etc., can solve the problems of low service life, large friction coefficient of equipment, and tipping, etc., to enhance the lateral stress divergence ability, ensure free expansion and contraction, and prevent lateral slanted effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention, but the present invention is not limited thereby.

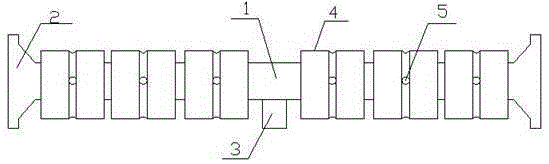

[0026] A stress relief roller, the total length of the roller is 210mm, including a roller shaft 1, the two ends of the roller shaft 1 are provided with limit plates 2, the middle part of the roller shaft 1 is provided with a support column 3, the lowest of the support column 3 end and the lowest end of the limit plate 2 are arranged on the same level, and the rollers 1 at both ends of the support column 3 are respectively provided with bearings 4, the inner diameter of the bearing 4 is 21mm, and the outer diameter of the bearing 4 is 28mm. 4 is 6, and there are 3 on both sides of the support column 3, the length of the roller 1 is greater than the total width of the bearing 4, the diameter of the roller 1 is 20mm, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com