An optimized β-mannanase gene man and its expression vector in Pichia pastoris

A mannanase and gene technology, applied in the field of genetic engineering, can solve problems such as reducing feed utilization and affecting the contact between nutrients and digestive juices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] Example 1 β-mannanase gene optimization and expression vector construction

[0079] 1) β-mannanase gene optimization and synthesis

[0080] The original β-mannanase gene VMAN was derived from a strain of Aspergillus niger that was screened and isolated from the natural soil near the konjac root. Its nucleotide sequence is shown in SEQ ID NO.1, and the encoded amino acid sequence is shown in SEQ ID NO.2. VMAN was codon-optimized (without changing the encoded amino acid sequence) and its stability was improved and then cloned into the pUC57 plasmid to obtain the optimized β-mannanase recombinant plasmid pUC57-MAN, whose nucleotide sequence is SEQ ID NO. 3.

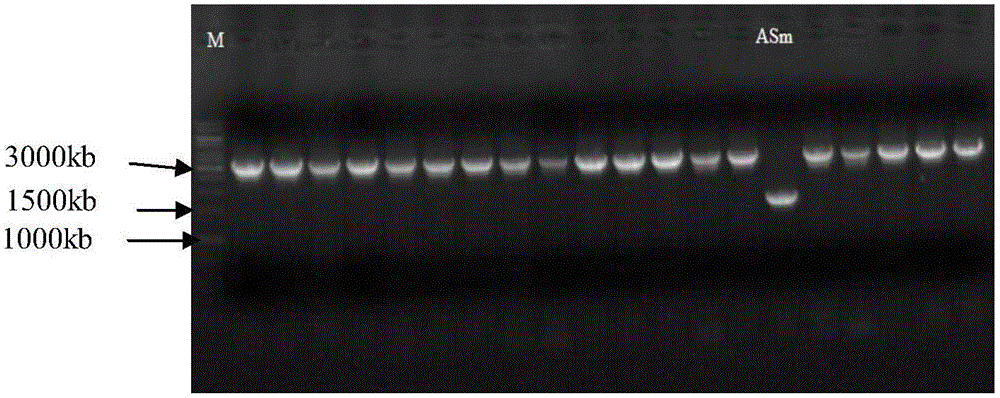

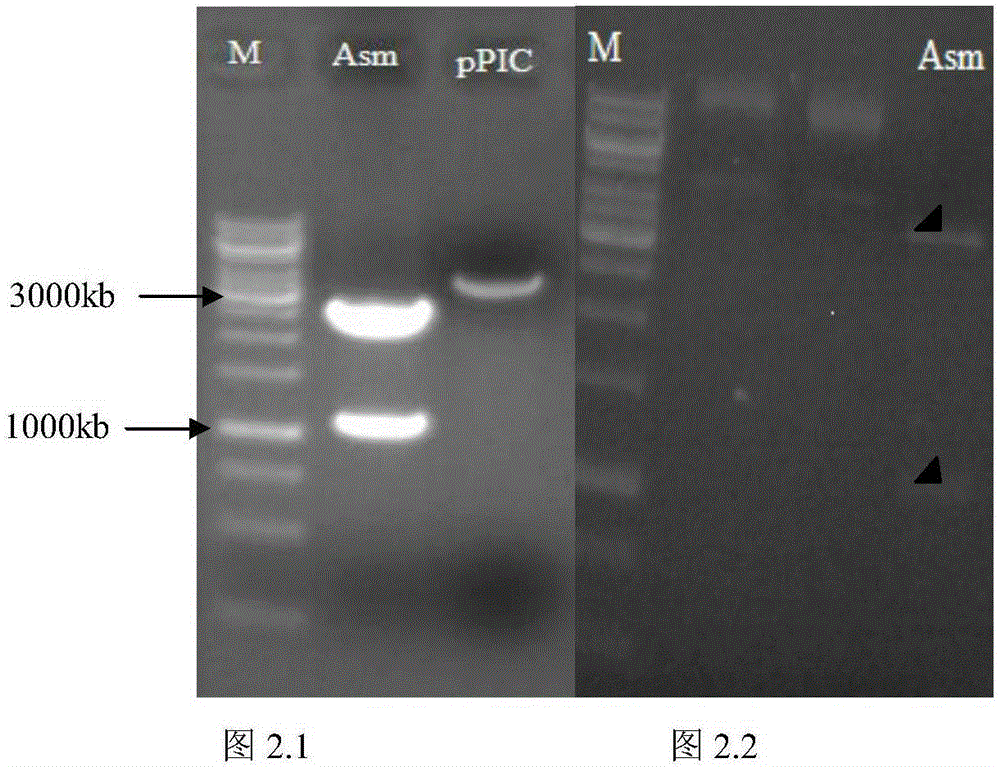

[0081] 2) Digestion and ligation

[0082] Use EcoRI and NotI to digest the pUC57-MAN recombinant plasmid and Pichia pastoris expression vector pPICZαA, use NEB’s T4 ligase to connect the two to construct pPICZαA-MAN, and transform the ligated product into E. Culture and screen positive clones. Plasmids of positiv...

Embodiment 2

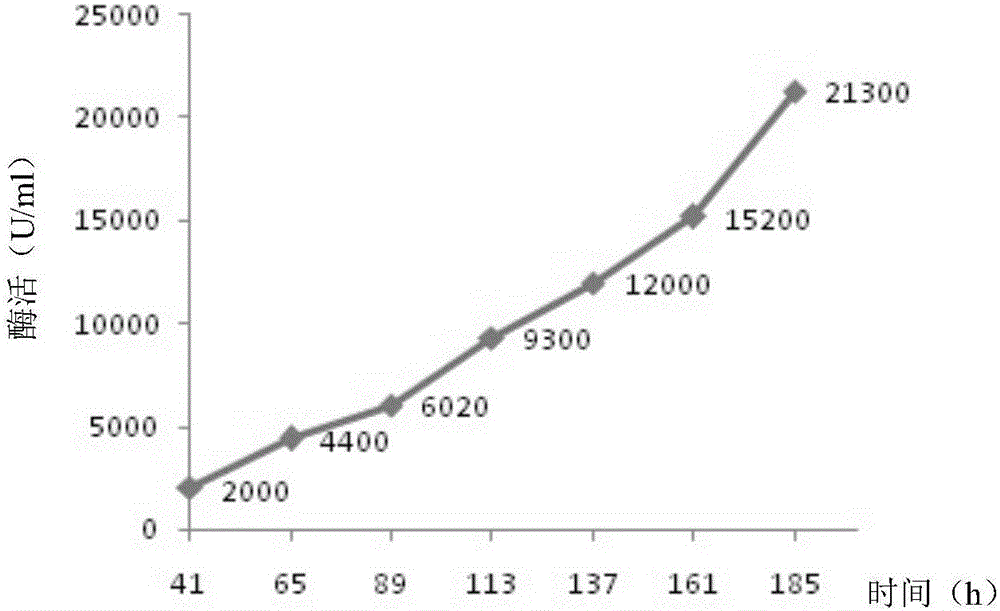

[0083]High-efficiency expression of the optimized β-mannanase recombinant strain of embodiment 2

[0084] The above-mentioned recombinant expression vector pPICzαA-MAN was linearized with SacI, and the linearized recombinant vector was electroporated to transform Pichia competent cells X33 to obtain Pichia recombinant strain X33 / MAN.

[0085] A single colony of the above-mentioned recombinant bacteria X33 / MAN was subjected to high-density fermentation culture. Configure 20L of basic salt medium, sterilize it in a 50L automatic control fermenter, and cool it to room temperature for later use. Adjust the pH value of the fermentation broth to 5.0 with ammonia water and phosphoric acid, control the dissolved oxygen to be greater than 30% by adjusting the rotation speed and air flow rate, and the fermentation temperature is 30°C. The entire fermentation process is divided into three stages: the first stage is the cell culture stage, inoculate the recombinant bacteria X33 / MAN-pPIC ...

Embodiment 3

[0086] Example 3 Activity analysis of the recombinant optimized β-mannanase

[0087] The reducing sugar produced by hydrolysis was determined by DNS method. The definition of each enzyme activity unit (U): Under the conditions of 55°C and pH 5.0, the amount of enzyme required to decompose β-mannan in locust bean gum per minute to produce a reducing ability equivalent to 1 μmol mannose. The experiment was repeated three times, and each sample was measured in three parallel experiments, and the relative error was controlled within 8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com