Water-in-oil drilling fluid and preparation method thereof

A technology of water-in-oil drilling fluid and base oil, which is applied in chemical instruments and methods, drilling compositions, inorganic pigment treatment, etc., can solve the problems of poor stability of water-in-oil drilling fluid, etc., and achieve good system stability. , good dispersing performance, remarkable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Synthesis of Amyl (R=5) Phenol Polyoxyethylene Ether (n=2) Sodium Carboxylate Betaine Modified Organic Soil

[0043] (1) Disperse 50 g of commercially available sodium bentonite into 600 g of water, and after high-speed stirring, remove impurities by suspension method to form a stable suspension system a;

[0044] (2) Mix 25g of amyl (R=5) phenol polyoxyethylene ether (n=2) sodium carboxylate betaine (40% by mass fraction) with 150g of water to form a homogeneous system b;

[0045] (3) Add b dropwise to a under high-speed stirring, and react at 30°C for 20 hours under normal pressure;

[0046] (4) Wash the product obtained in step (3) 5 times, then dry the product at 80°C, and pulverize it to obtain particles with a particle size below 78 μm, that is, amyl (R=5) phenol polyoxyethylene ether ( n=2) Sodium carboxylate betaine modified organic soil.

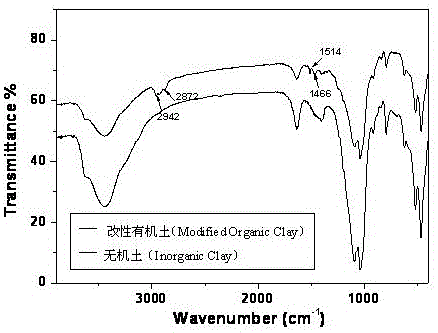

[0047] figure 1 Amyl (R=5) phenol polyoxyethylene ether (n=2) sodium carboxylate betaine modified organic soil and comme...

Embodiment 2

[0051] Steps (1) to (4) are the same as [Example 1], except that amyl (R=5) phenol polyoxyethylene ether (n=2) hydroxysulfonate sodium betaine is used to replace amyl (R=5) phenol Polyoxyethylene ether (n=2) sodium betaine carboxylate was used as modifier of organic soil.

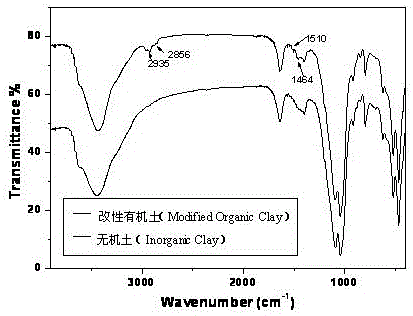

[0052] figure 2 Amyl (R=5) phenol polyoxyethylene ether (n=2) hydroxysulfonate sodium betaine modified organic soil and commercially available sodium bentonite infrared absorption spectra, it can be seen that amyl (R=5) phenol The infrared absorption spectrum of organic soil modified by polyoxyethylene ether (n=2) sodium hydroxysulfonate betaine at 2935cm -1 and 2856cm -1 Presents an obvious C-H stretching vibration peak at 1464cm -1 The bending vibration peak of C-H appears at 1510cm -1 The stretching vibration peak of the benzene ring appears. It can be seen that the difference between the organic modified soil and the original soil in the infrared absorption spectrum is mainly due to the change of ...

Embodiment 3

[0055] Synthesis of Nonyl (R=9) Phenol Polyoxyethylene Ether (n=7) Sodium Carboxylate Betaine Modified Organic Soil

[0056] (1) Disperse 45g of commercially available sodium bentonite into 600g of water, and after high-speed stirring, remove impurities by suspension method to form a stable suspension system a;

[0057] (2) Mix 9 g of nonyl (R=9) phenol polyoxyethylene ether (n=7) sodium betaine carboxylate (50% by mass fraction) with 100 g of water to form a homogeneous system b;

[0058] (3) Add b dropwise to a under high-speed stirring, and react at 80°C for 4 hours under normal pressure;

[0059] (4) Wash the product obtained in step (3) for 3 times, then dry the product at 120°C, and pulverize it to obtain particles with a particle size below 78 μm, that is, nonyl (R=9) phenol polyoxyethylene ether (n =7) Sodium carboxylate type betaine modified organic soil.

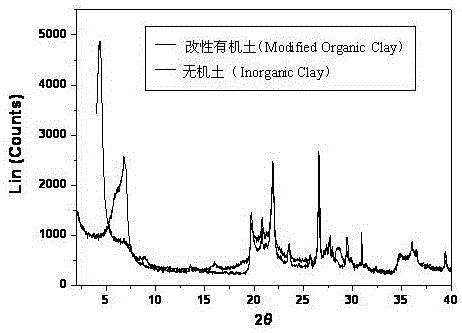

[0060] image 3 It is the XRD spectrum of nonyl (R=9) phenol polyoxyethylene ether (n=7) sodium betaine carbo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| filtration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com