Cable rope maintaining robot

A technology of robots and cables, applied in the field of robots to achieve the effect of advanced technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

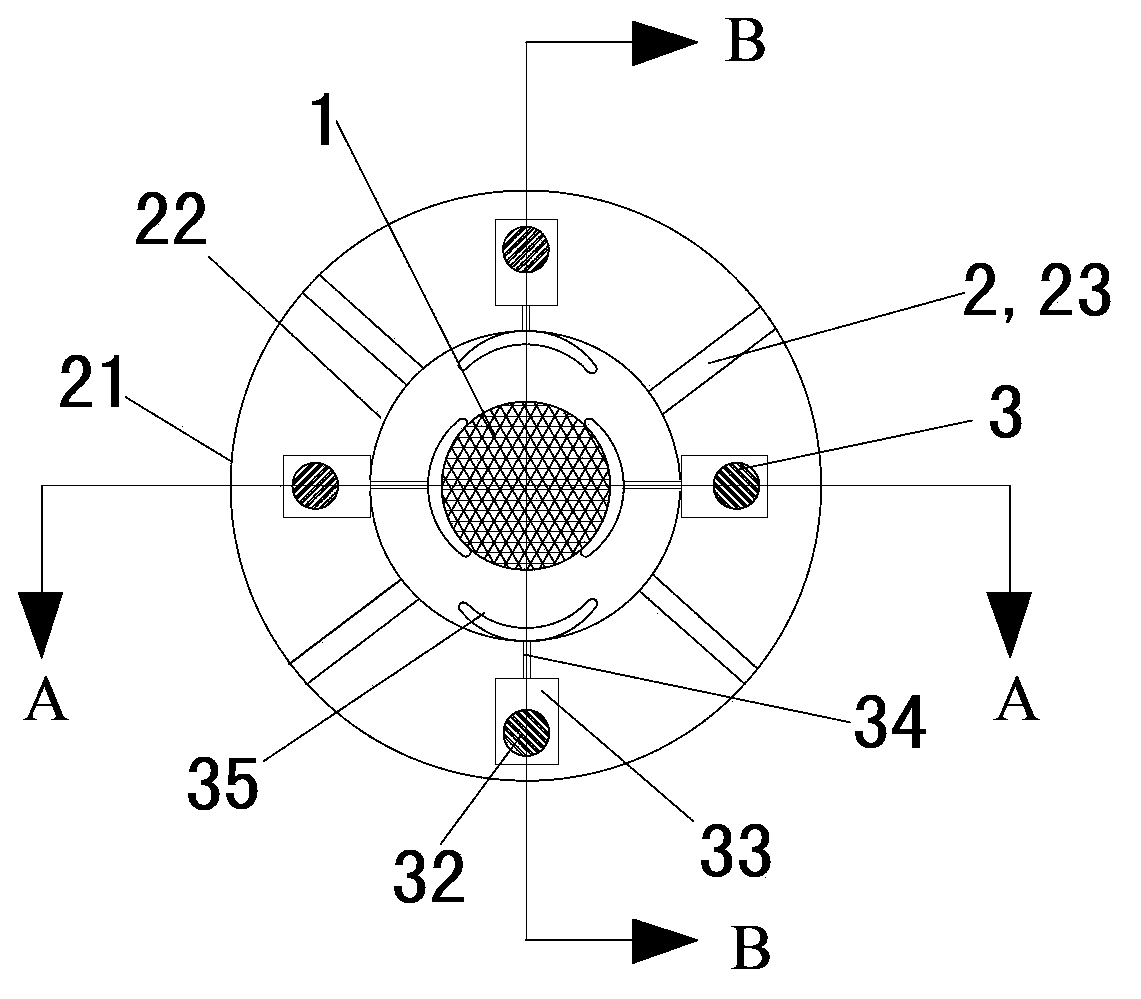

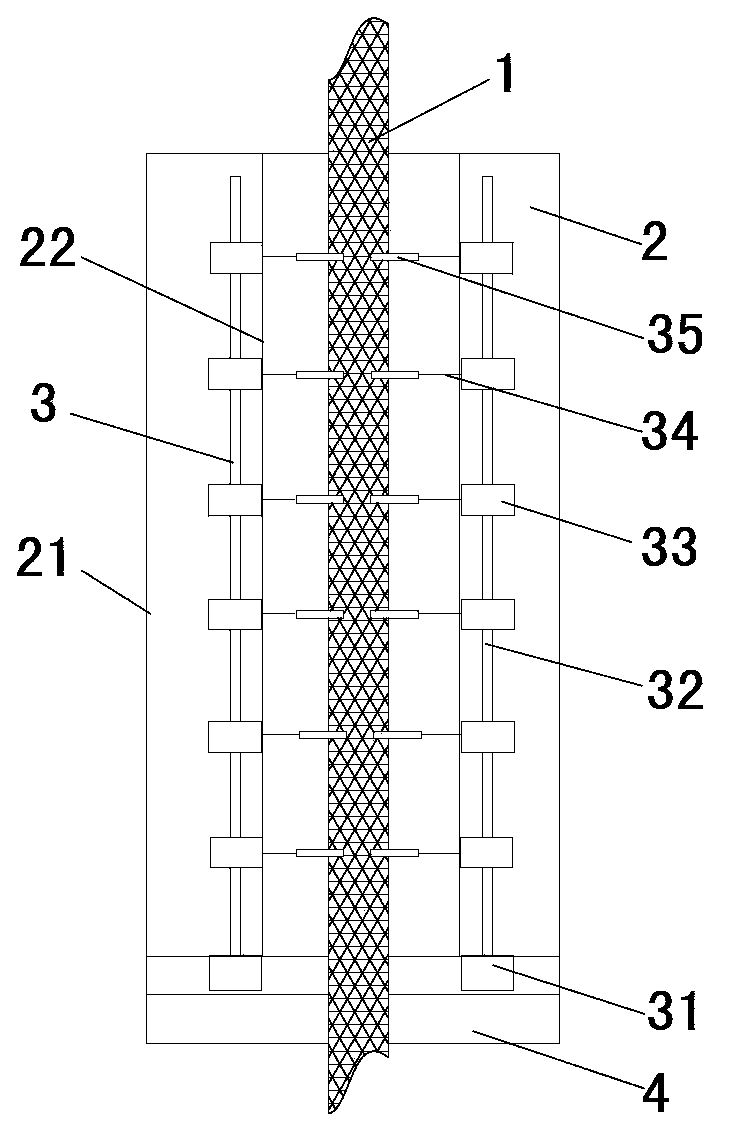

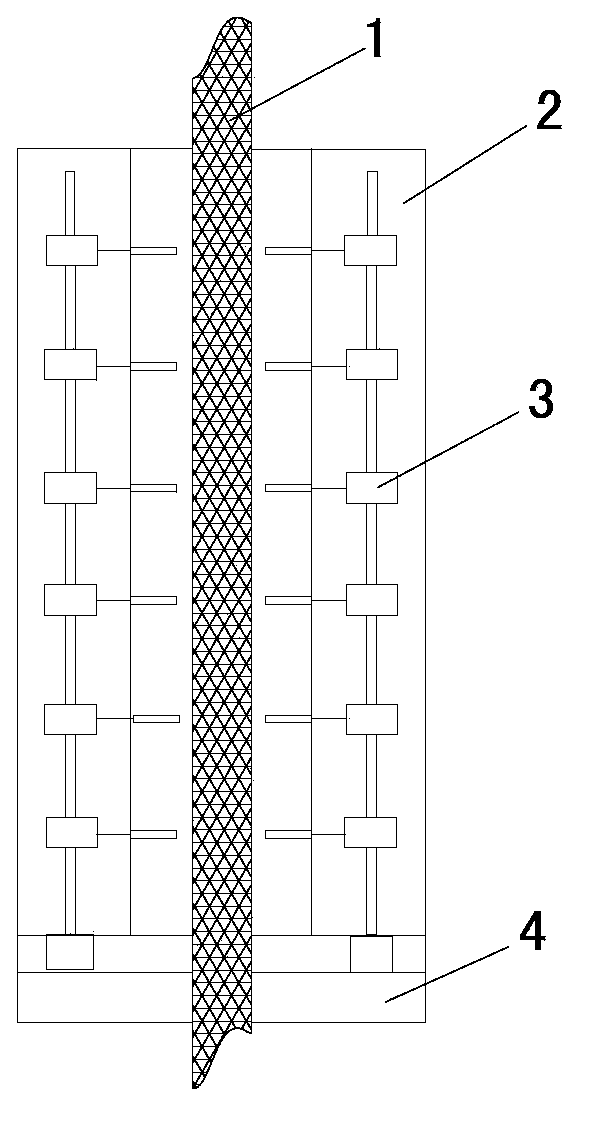

[0014] see figure 1 , figure 2 , image 3 , Figure 4 , the cable maintenance robot of the present invention is suspended on the cable 1, and includes a robot skeleton 2, four sets of climbing mechanisms 3 and a climbing control mechanism 4, the robot skeleton 2 is movably sleeved on the cable 1, four sets of climbing mechanisms 3 and a climbing control mechanism 4 They are respectively arranged in the robot skeleton 2; among them, four groups of climbing mechanisms 3 are symmetrically distributed in pairs around the cables and can alternately clamp the cables in pairs, and the climbing control mechanism 4 controls the four groups of climbing mechanisms to alternately climb along the cables in pairs, thereby Drive the entire cable maintenance robot to move along the cable.

[0015] The above-mentioned robot skeleton 2 includes an outer layer made of a cylindrical shell 21 and an inner layer made of four arc-shaped plates 22. The four arc-shaped plates 22 are evenly spaced ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com