Material picking mechanism of injection molding product feeder

A technology of reclaiming mechanism and injection molding products, applied in the field of reclaiming mechanism of injection molding product feeder, can solve the problems of large device structure, inability to install, complicated gripper unit device, etc. The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with drawings and embodiments.

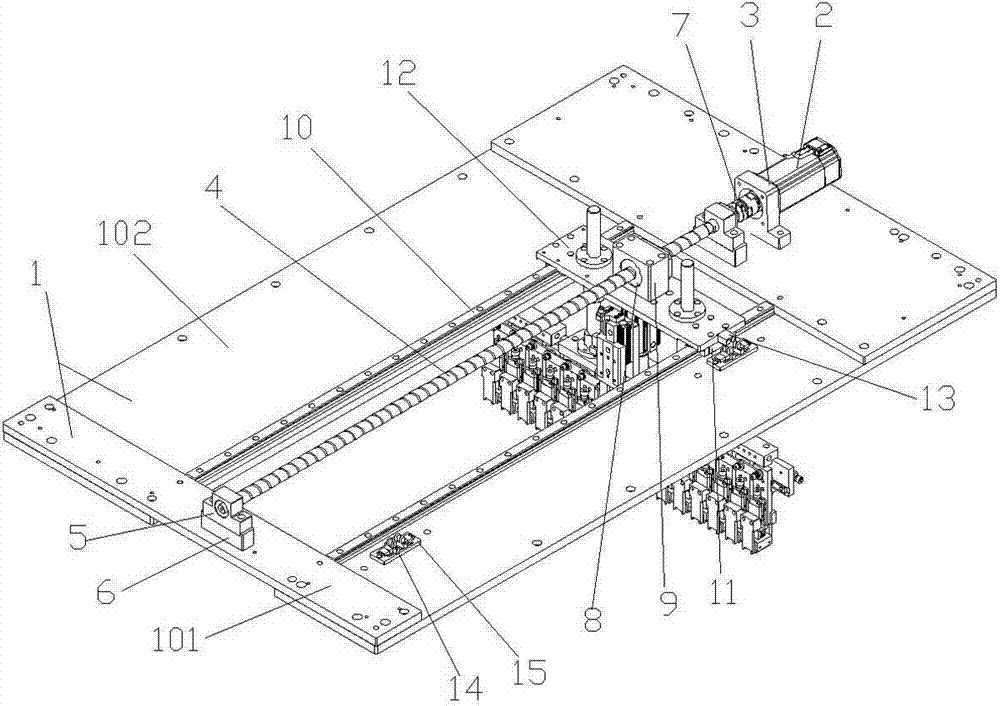

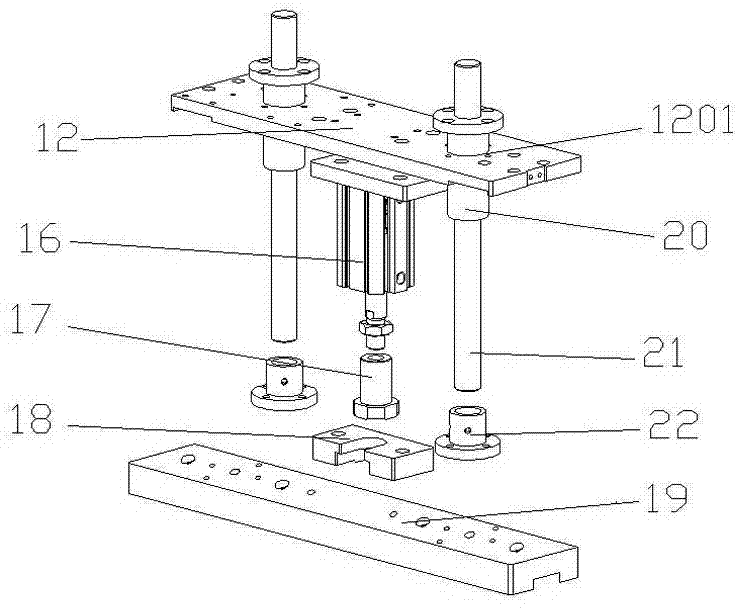

[0035] figure 1 It is an overall three-dimensional structure diagram of Embodiment 1 of the present invention. As shown in the figure, there are four base plates 1, two vertical and two horizontal ones are installed in the shape of a "mouth", and are divided into a vertical base plate 101 and a horizontal base plate 102. The servo motor 2 is installed on one of the longitudinal base plates 101 through the motor fixing seat 3, and the two ends of the screw rod 4 are respectively installed in the screw fixing seat 5, and the screw fixing seat 5 is respectively installed on the two sides through the fixing pad 6. On the vertical base plate 101, one end of the screw rod 4 forms a rotatable connection with the motor shaft of the servo motor 2 through the coupling 7, the screw nut 8 is sleeved on the screw rod 4, and the screw nut 8 is also covered with a wire There are two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com