Mobile robot hole forming platform based on composite axle structure

A technology for robot hole making and compound car, which is applied in the field of mobile robot hole making, can solve the problems of weak load-carrying capacity and easy wear of Mecanum wheels, ensure accuracy and reliability, reduce wear, and reduce steering. small space effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

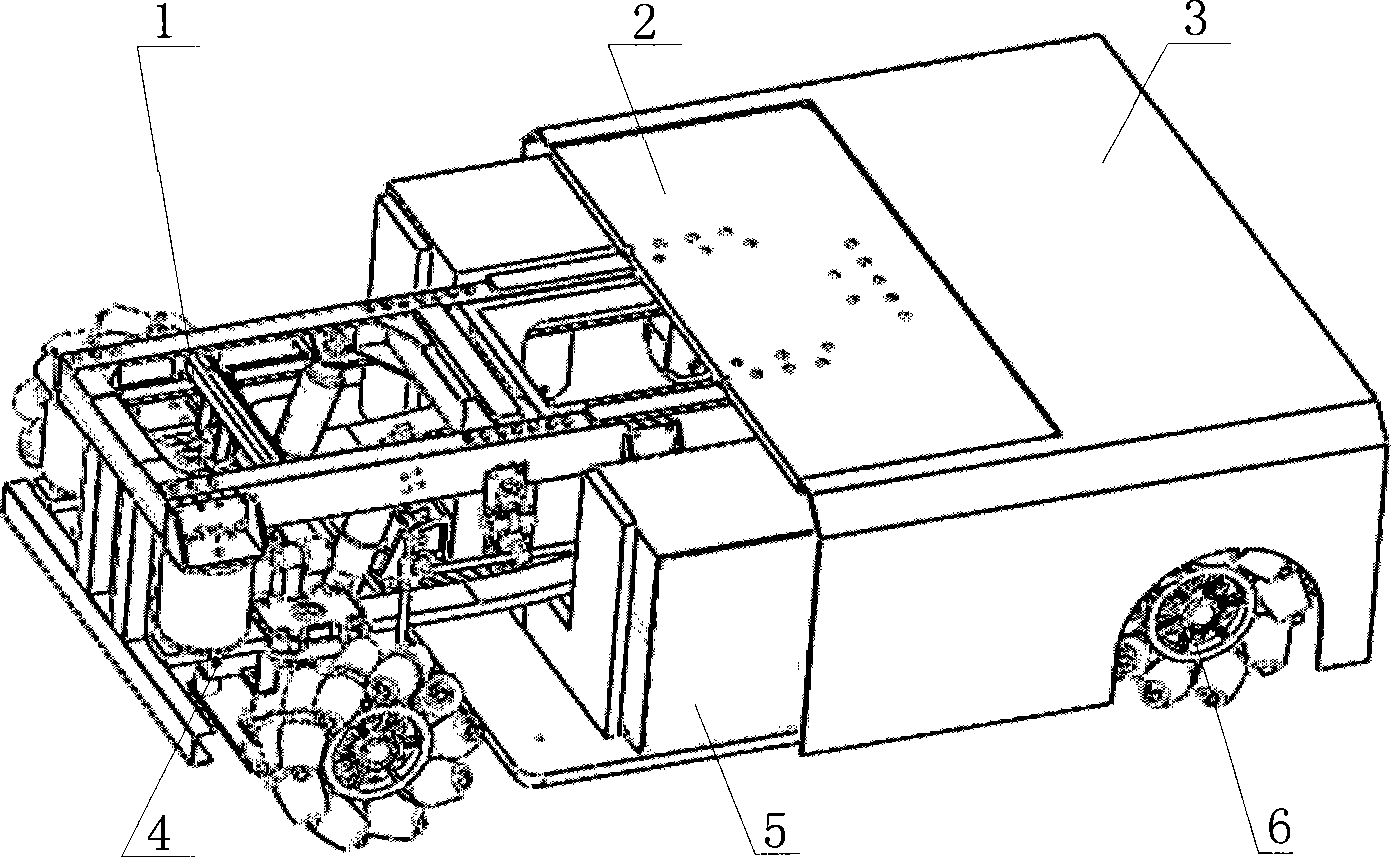

[0022] figure 1 The overall structure diagram of the mobile robot drilling platform based on the composite axle structure. right figure 1 Each part is described as follows:

[0023] 1. Suspension unit 2. Load locking unit 3. Frame unit 4. Axle and drive unit 5. Control integration unit 6. Omni-directional wheels

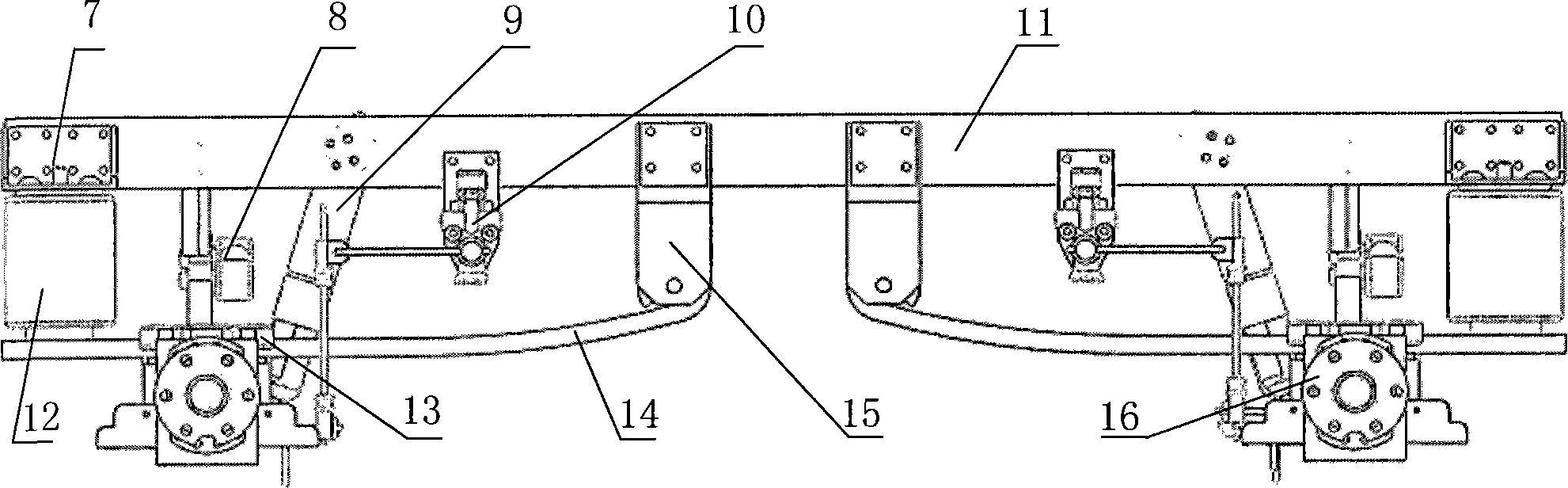

[0024] figure 2 It is a structural diagram of an air spring suspension that can be adjusted in height. Each part is described as follows:

[0025] 7. Air spring bracket 8, tie rod 9, shock absorber 10, height valve 11, frame structure 12, air spring 13, axle cover 14, leaf spring 15, leaf spring bracket 16, axle

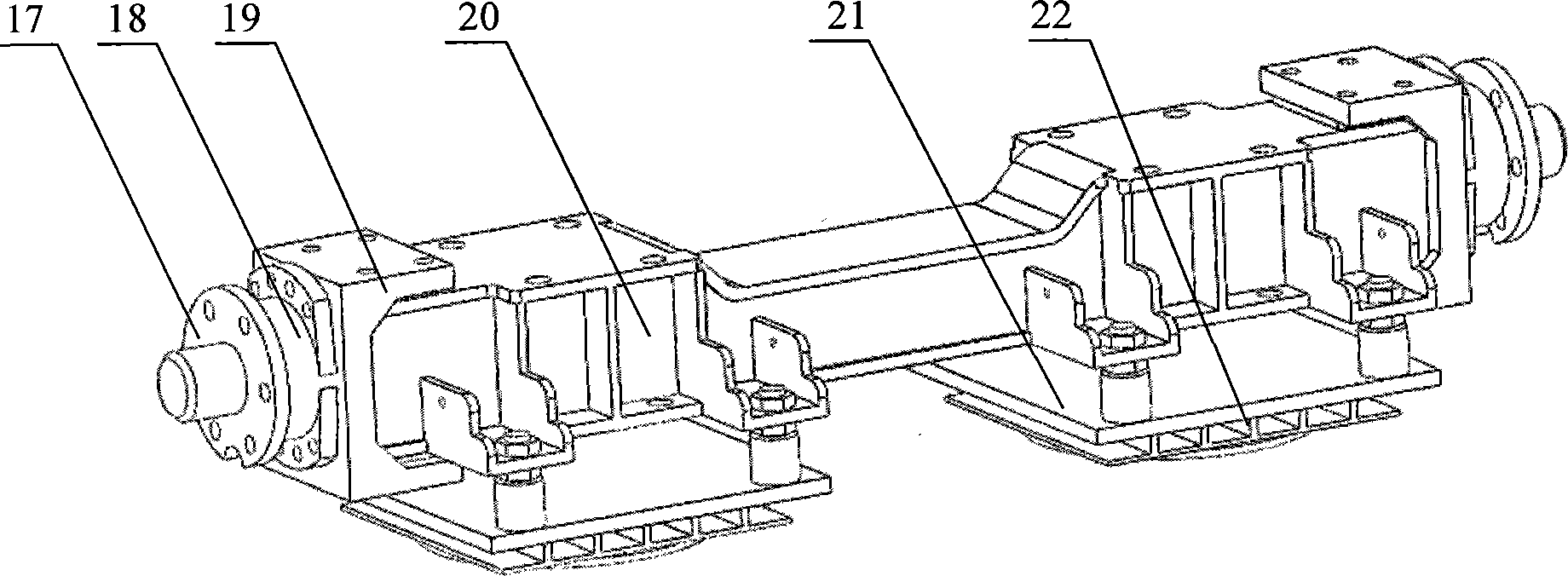

[0026] image 3 It is a composite axle structure diagram. Each part is described as follows:

[0027] 17. Hub mounting flange 18, bearing housing 19, motor mounting flange 20, co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com