Surface soil processing component

A technology for components and topsoil, applied in the field of topsoil processing components, can solve the problems of poor soil crushing effect, easy blocking of soil crushing rollers, heavy quality, etc., and achieve the effects of improving work quality, expanding work adaptability, and leveling the surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

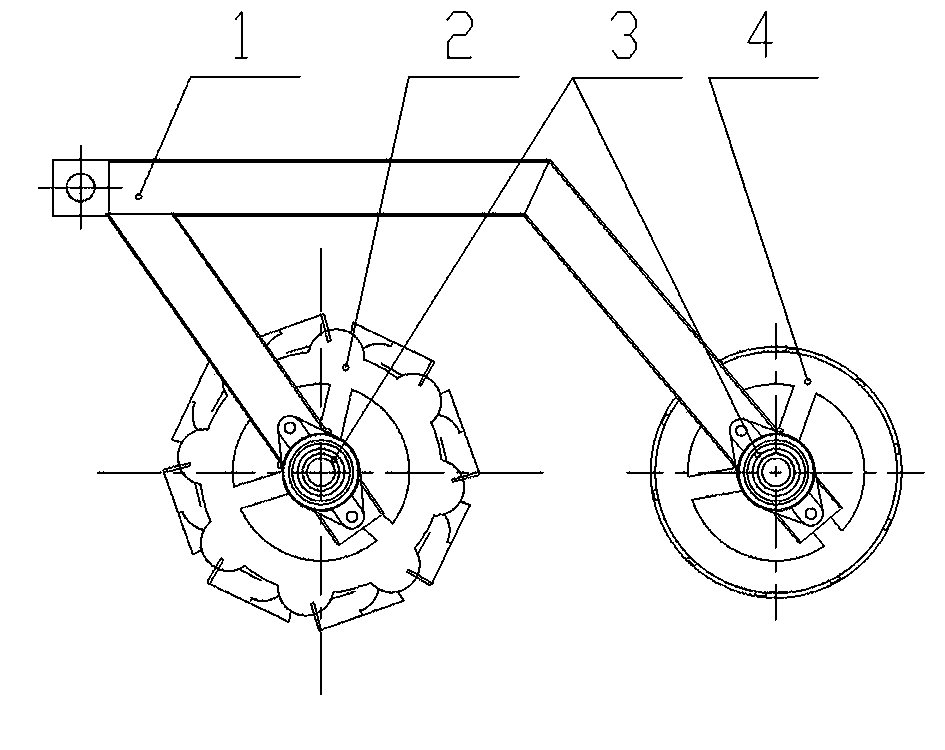

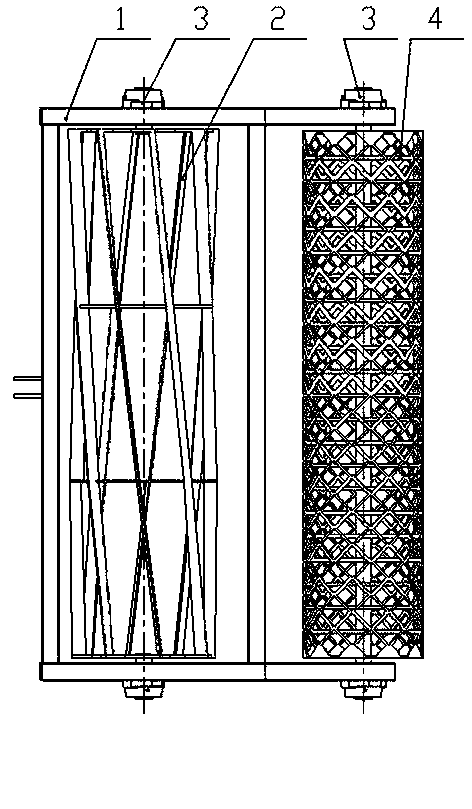

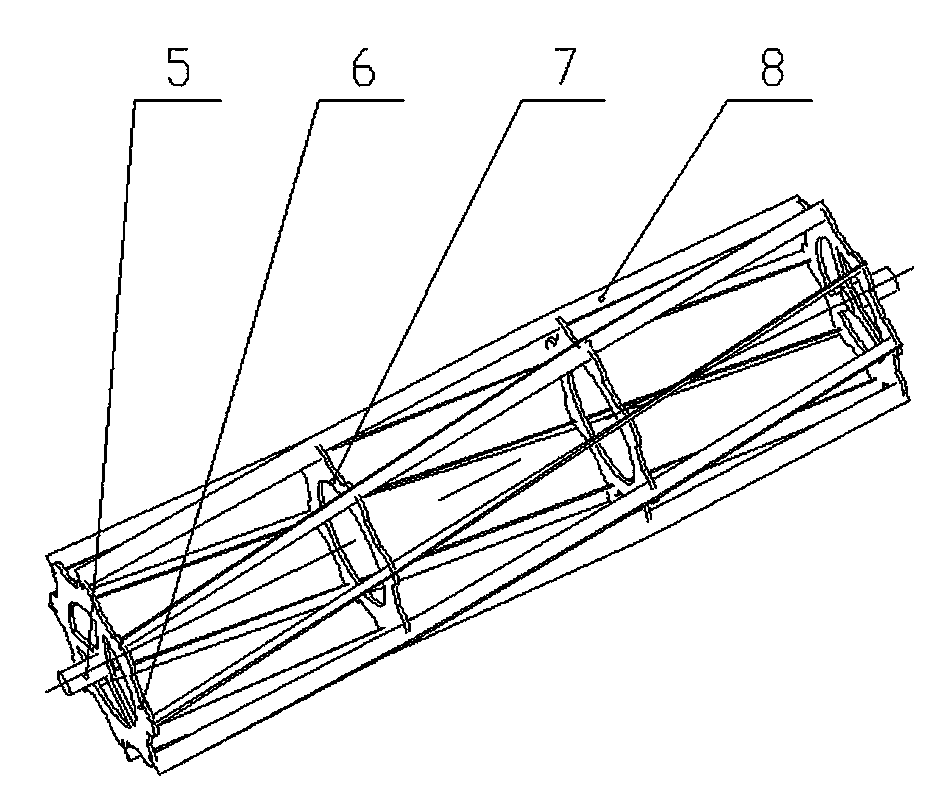

[0013] The best embodiment of the topsoil processing component of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0014] The invention includes a frame (1), a hollow soil crushing roller (2), and an anilox suppressor (4), and is characterized in that: the hollow soil crushing roller (2) is installed in front of the frame (1) through a bearing (3) The anilox suppressor (4) is installed at the rear of the frame (1) through the bearing (3); the hollow soil crushing roller (2) consists of a shaft head (5), a soil crushing roller end plate (6), a soil crushing The roller partition (7) and the soil crushing plate (8) are composed, the shaft head (5) is welded to the soil crushing roller end plate (6), and the soil crushing roller partition (7) is on the left and right two soil crushing roller end plates (6) are uniformly distributed among them, and the soil crushing plate (8) is spirally wound and welded on the outer circumfer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com