Clutch unit

A clutch, friction clutch technology, applied in the direction of clutch, friction clutch, mechanical drive clutch, etc., can solve unnecessary problems and achieve the effect of less space requirement, reduced loss, and reduced drag torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

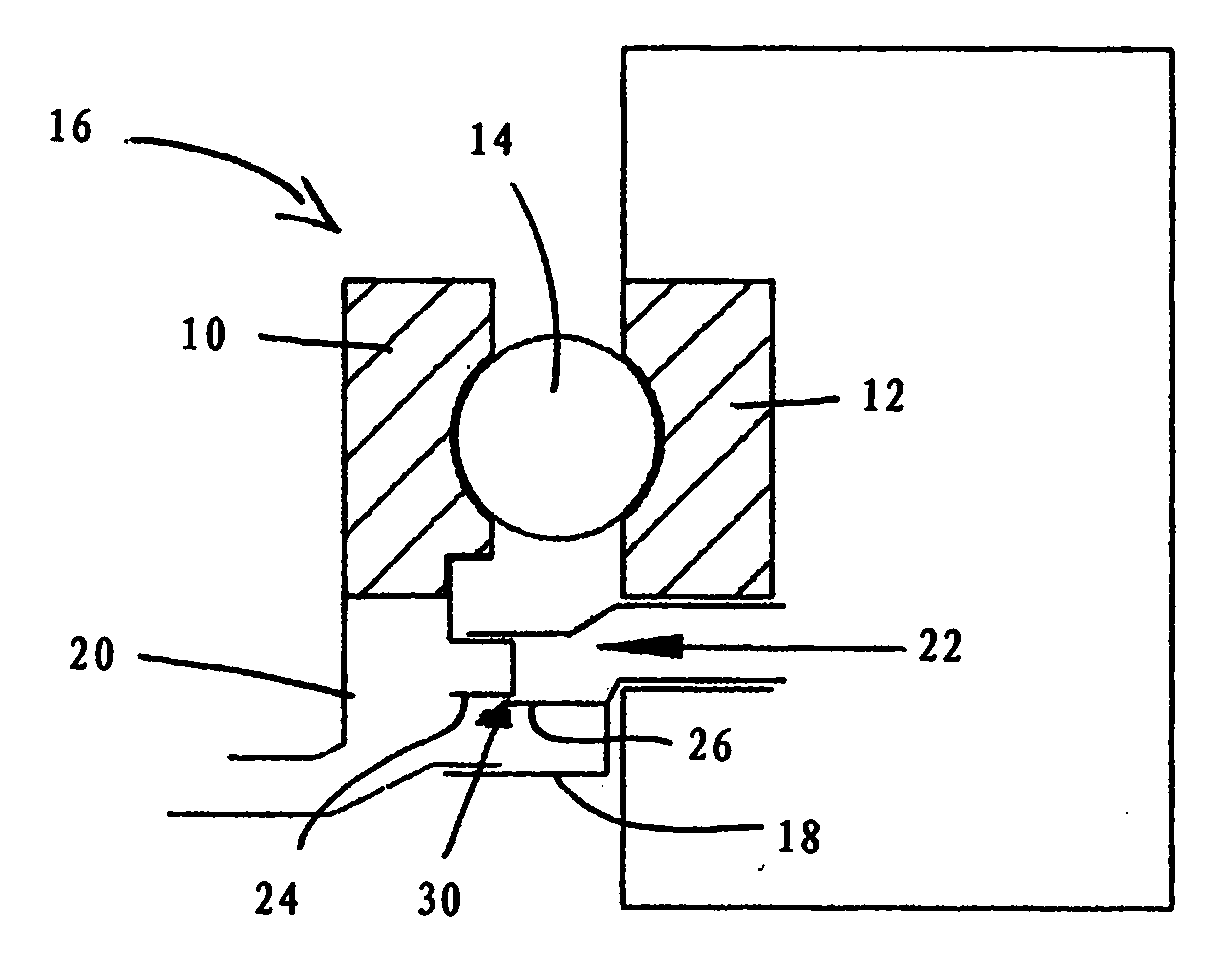

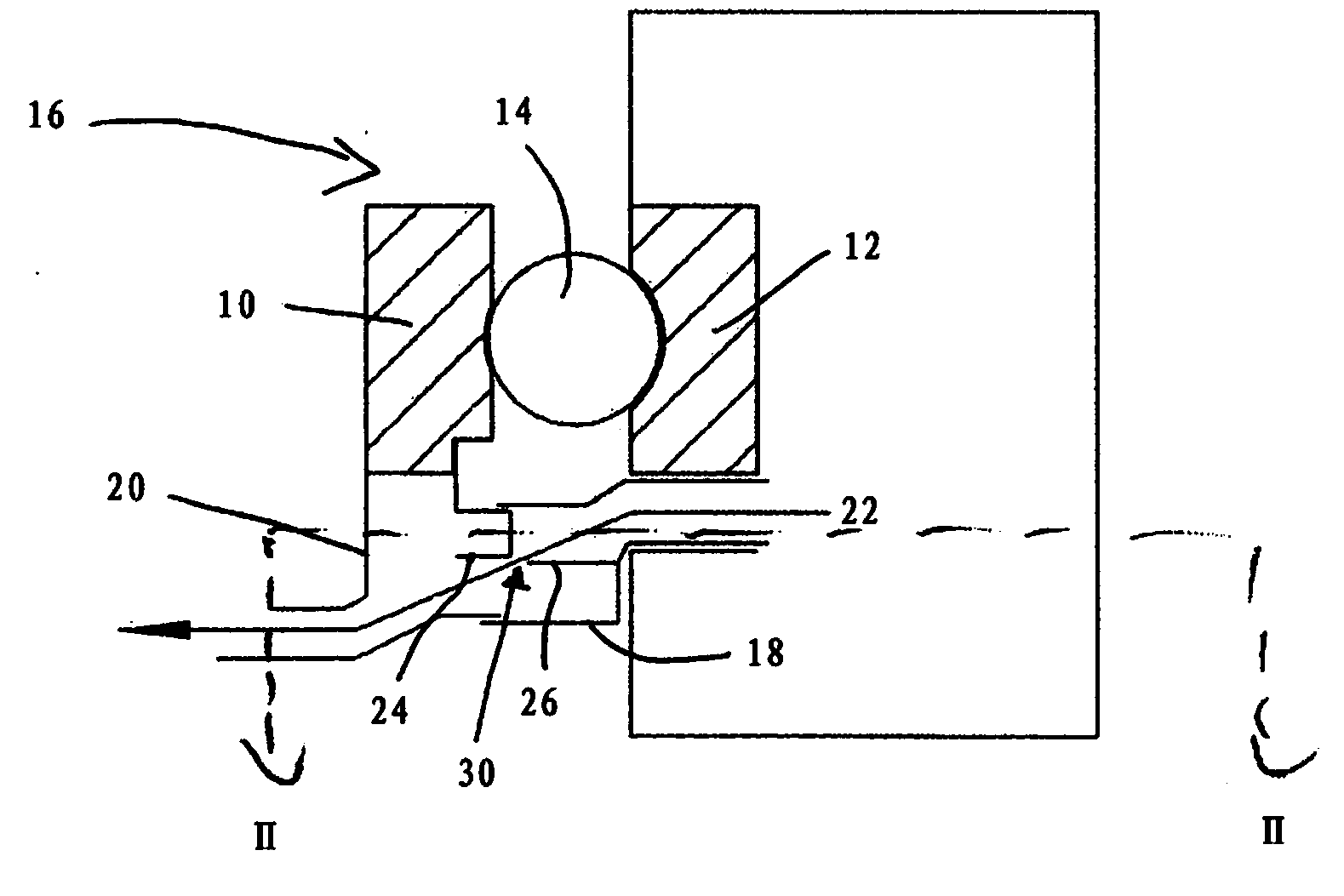

[0031] exist Figure 1a and 1b The clutch unit described in has an integrated metering device for the cooling fluid used for cooling and lubricating the friction clutches of the clutch unit. The friction clutch is not shown here.

[0032] The clutch unit comprises a first ramp ring 10 and a second ramp ring 12 with a plurality of rolling elements 14 interposed therebetween. Together with associated drive means, such as an electric motor, not shown, these elements form an actuator 16 for the friction clutch. The second bevel ring 12 is here stationary (that is to say rotationally fixed and fixed in the axial direction), whereas the first bevel ring 10 is rotatable and axially fixed relative to the second bevel ring 12 . is movable. Alternatively, it is also possible, for example, for the two ramp rings 10 , 12 to rotate in opposite directions, wherein the second ramp ring 12 is supported in the axial direction and the first ramp ring is additionally movable in the axial dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com