Entropy method for determining concrete-filled steel tube bearing force design error distribution

A technology of concrete filled steel tube and design error, which is applied in the direction of calculation, special data processing application, instrument, etc., to achieve the effect of simple technical characteristics and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

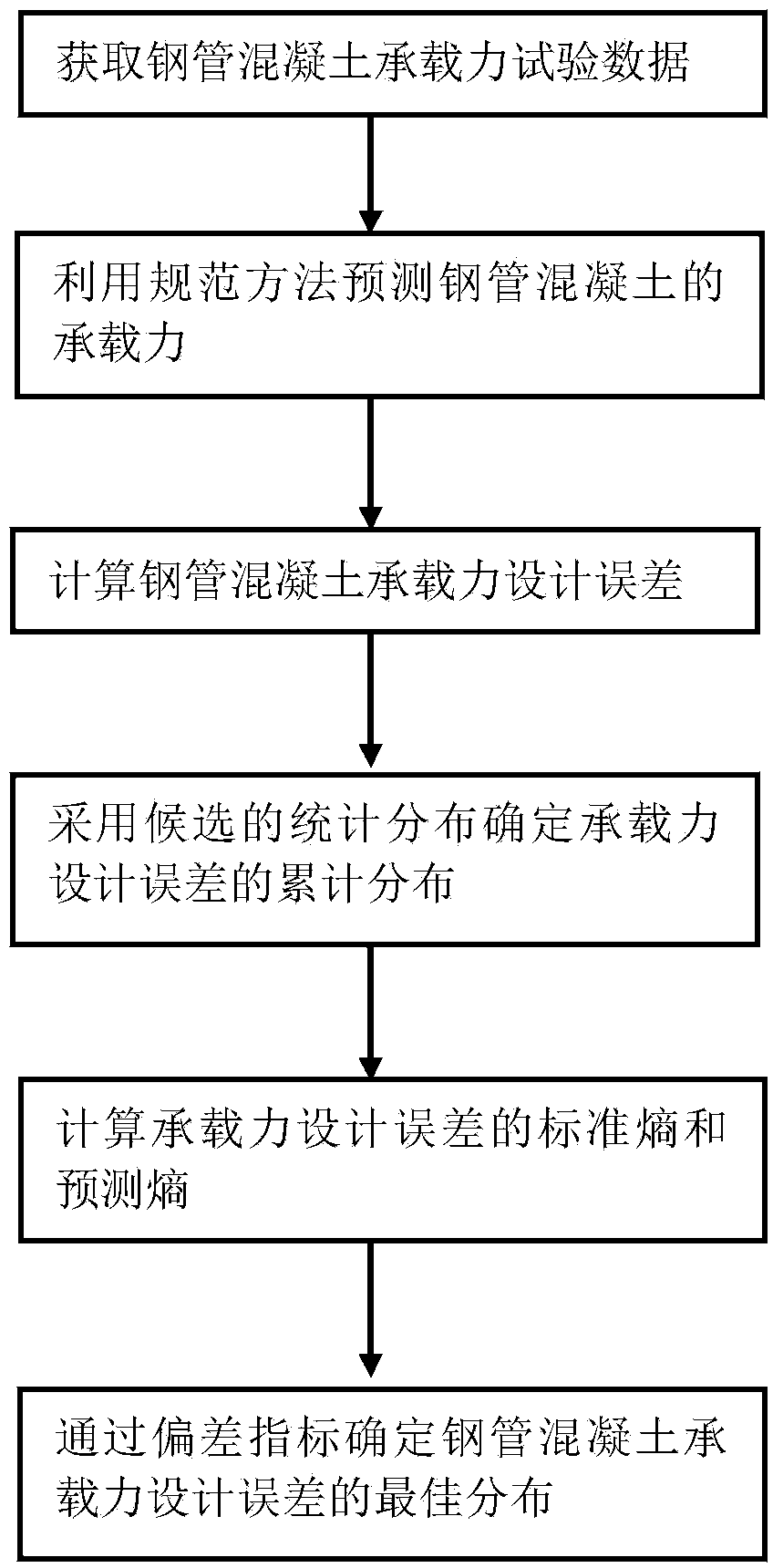

Method used

Image

Examples

Embodiment 1

[0062] (1) The present invention takes the axial loading test of 250 circular steel tube concrete specimens as an example, and obtains the test data N of the bearing capacity of steel tube concrete e . (See: Data from Z.H.Lu, Y.G.Zhao, Z.W.Yu, F.X.Ding and T.Ono. Model error uncertainty in the design code provisions for circular CFT stub columns. Proceedings of the International Symposium on Reliability Engineering and Risk Management, 2,908 -918, 2010.).

[0063] (2) Using the steel pipe bearing capacity design codes of four different countries, including China's DL / T1999, Japan's AIJ1997, Europe's EU2004, and the United States' AISC2005, the bearing capacity of CFST is predicted N p .

[0064] (3) The expression of design error through bearing capacity:

[0065] M = N e N p

[0066] The sample data of M is calculated.

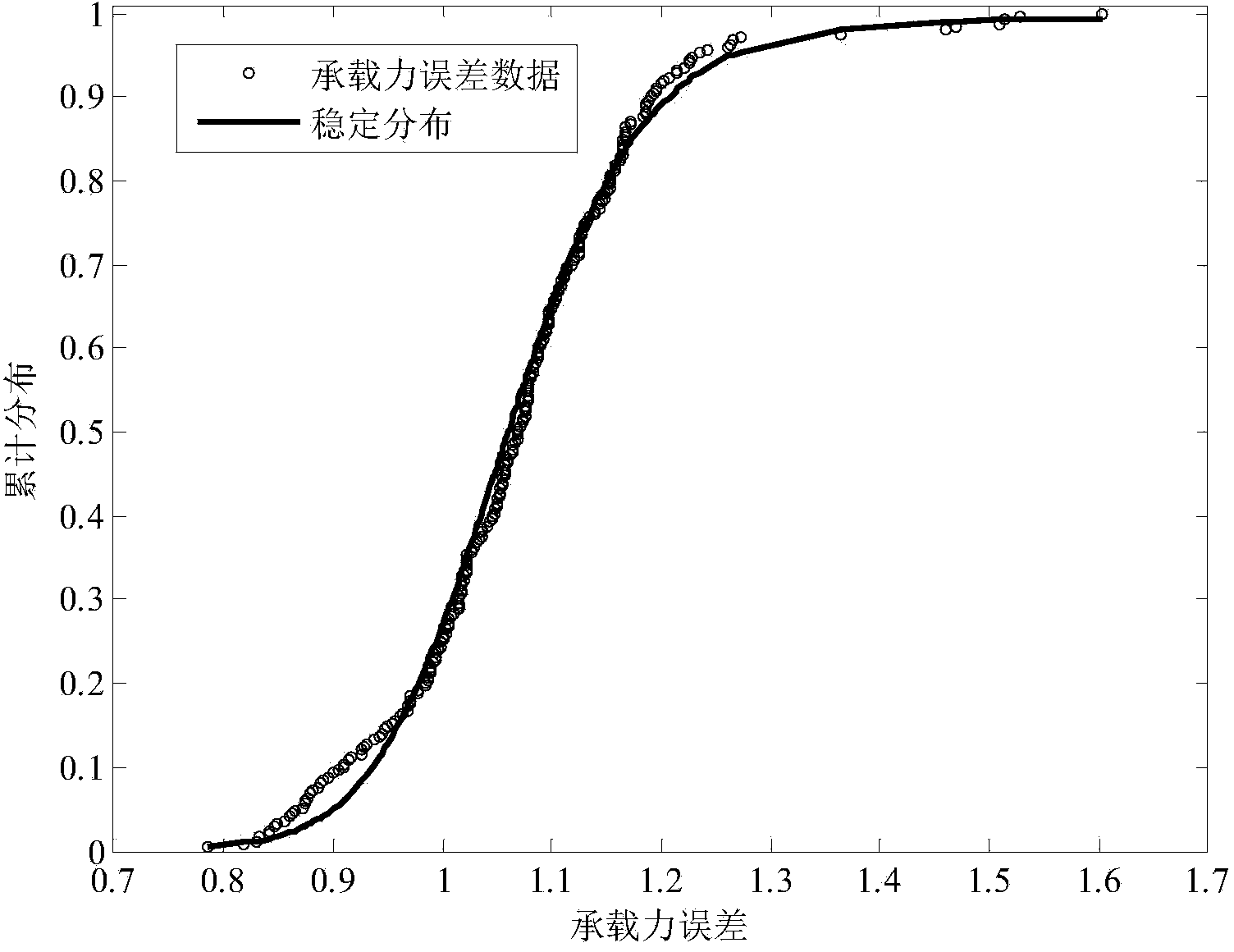

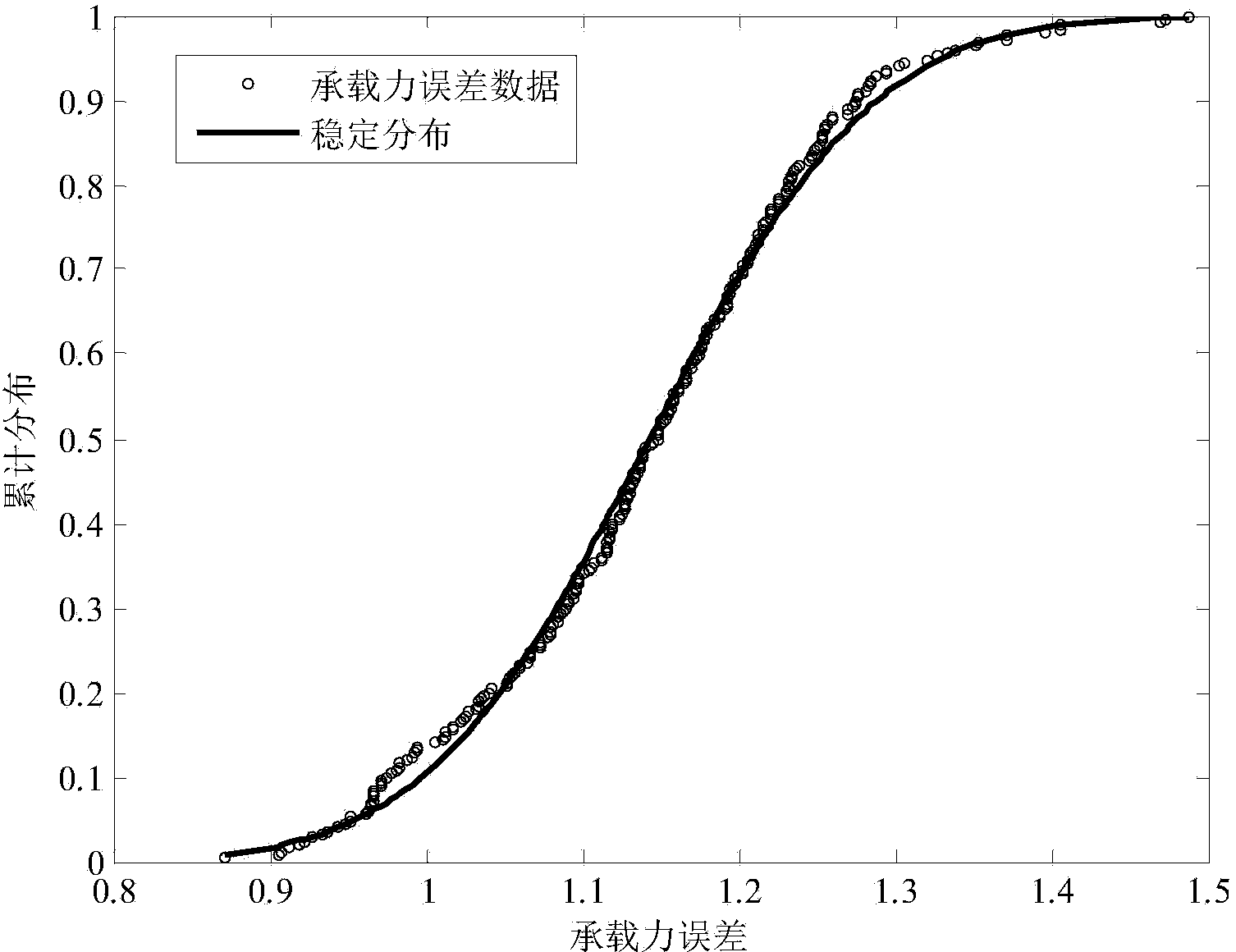

[0067] (4) Select stable dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com