Driving assembly, roller and processing box

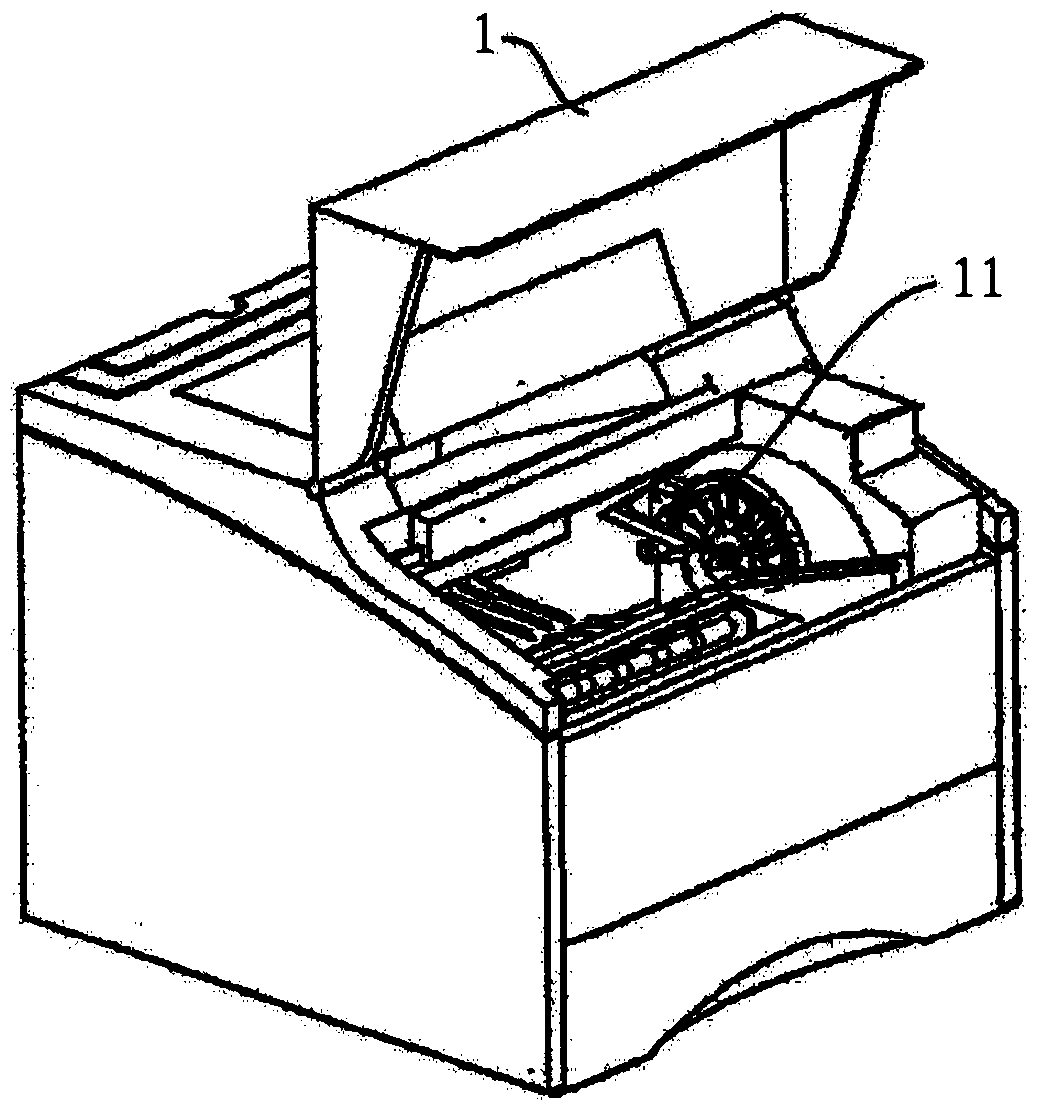

A technology of driving components and driving parts, applied in the field of rollers and process cartridges, can solve problems such as photosensitive drums or developing rollers unable to receive driving force, process cartridges or imaging devices not working normally, drive components and drive shafts stuck, etc., to achieve Reliable performance, reliable fit and connection, and stable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

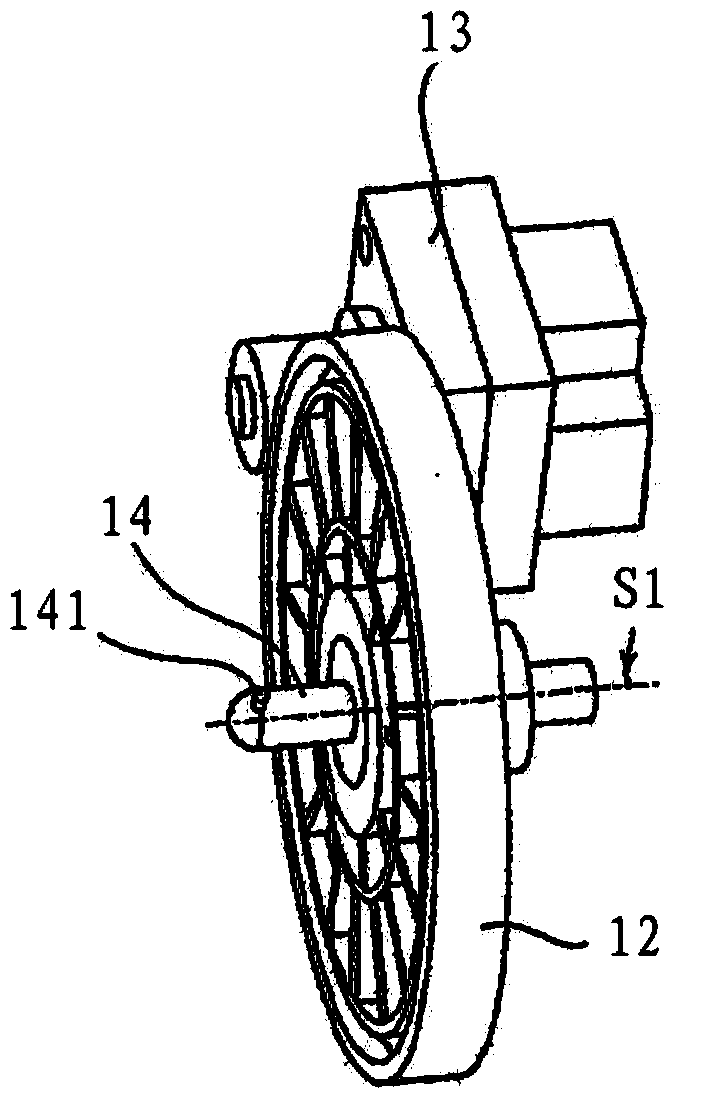

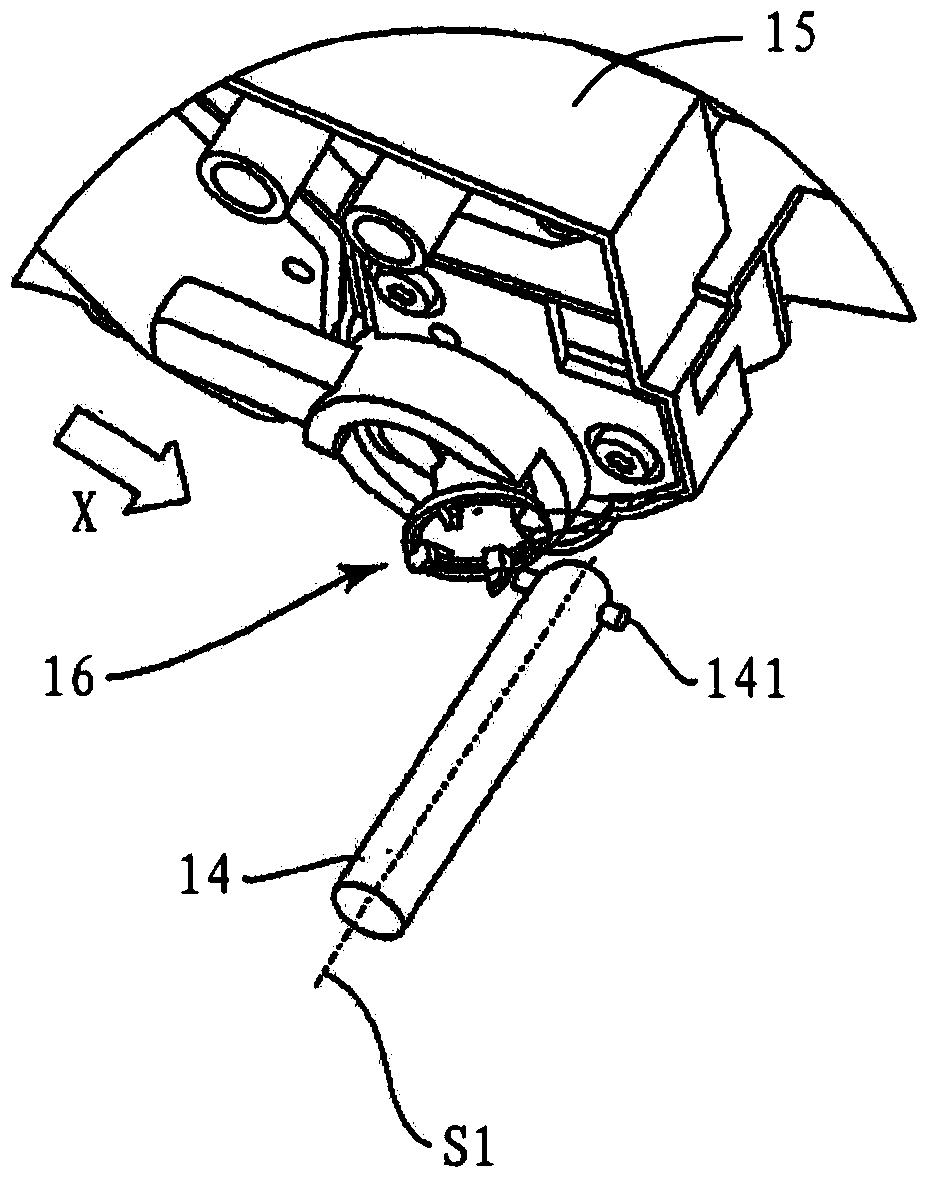

[0049] refer to Figure 4 , Figure 5 and Figure 6 , the driving assembly 2 includes a gear seat 21, a connecting piece 5, a driving wheel receiving piece 3 and a positioning assembly. The driving assembly 2 is installed on the end of the photosensitive drum, developing roller, powder feeding roller, etc., and receives the rotational driving force transmitted from the imaging device such as a printer or copier through the driving wheel receiving part 3, and then transmits the rotating driving force through the connecting part 5 The force thus drives the gear seat 21 to rotate. The housing of the gear seat 21 is formed with an accommodating chamber 26 concaved inward along the axial direction of the gear seat 21. The accommodating chamber 26 is a cylindrical cavity with a bottom, and an opening 24 is provided at one end of the accommodating chamber 26. On the gear seat 21 A fixed end 23 is provided on the other end of the outer wall relative to the opening 24 , and a gear 2...

no. 2 example

[0063] refer to Figure 18 and Figure 19 , on the basis of the first embodiment of the drive assembly, the positioning piece 4 in the first embodiment is designed as Figure 18 The shown positioning sheet 6, the positioning sheet 6 includes a first half sheet 61 and a second half sheet 62, the first half sheet 61 and the second half sheet 62 are respectively provided with a half through hole, the first half sheet 61 and the second half sheet 62 A through hole 63 is formed when mated with each other. When the positioning piece 6 is installed in the positioning groove of the drive assembly, the through hole 63 fits on the rod body and makes the central axis of the driving force receiver parallel to the central axis of the gear seat. The main purpose of the present invention can also be achieved by the positioning piece 6 . Compared with the positioning piece 4 of the first embodiment, the positioning piece 6 of this embodiment lacks the boss 45 of the positioning piece 4, be...

no. 3 example

[0065] On the basis of the first embodiment of the driving assembly, a pin shaft 74 and a spring 77 can also be arranged in the accommodation cavity 76 of the gear seat 71 . refer to Figure 20 and Figure 21 , the axial length of the pin shaft 74 is set to be less than or equal to the diameter of the housing cavity 76, and a through hole 721 is opened at the position where the rod body 72 is located in the housing cavity 76, and the pin shaft 74 passes through the through hole 721, so that the driving force The receiving part can slide along the pin shaft 74 and the pin shaft 74 can move in the receiving cavity 76 along the axial direction of the receiving cavity 76 . The spring 77 is installed in the accommodating cavity 76 , one end of which abuts against the bottom surface 761 of the accommodating cavity 76 , and the other end abuts against the pin shaft 74 . When the driving force receiving part is connected with the driving wheel, the driving force receiving part will ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com