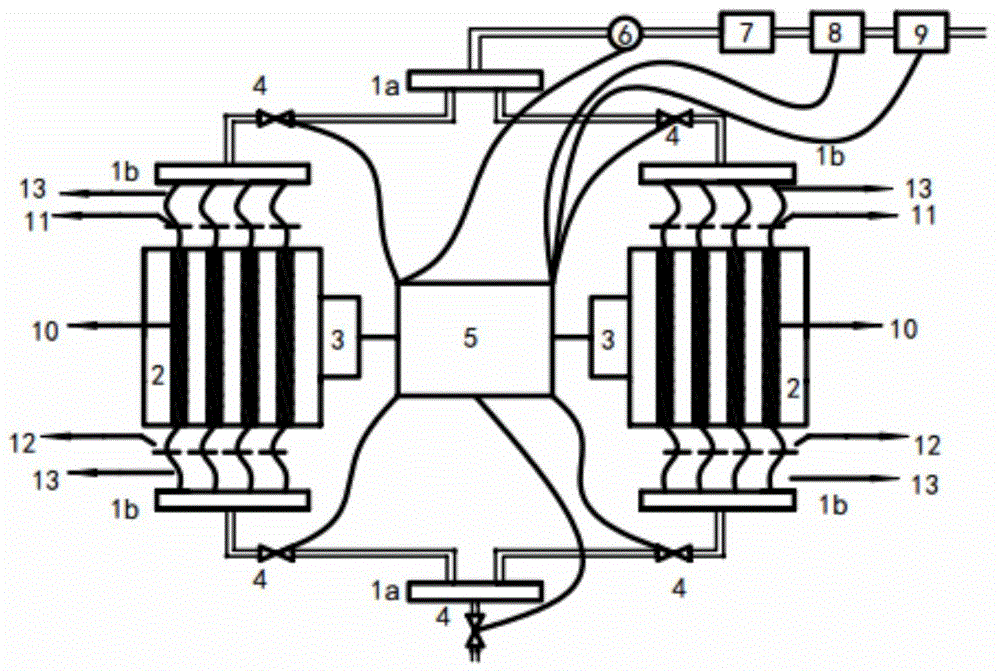

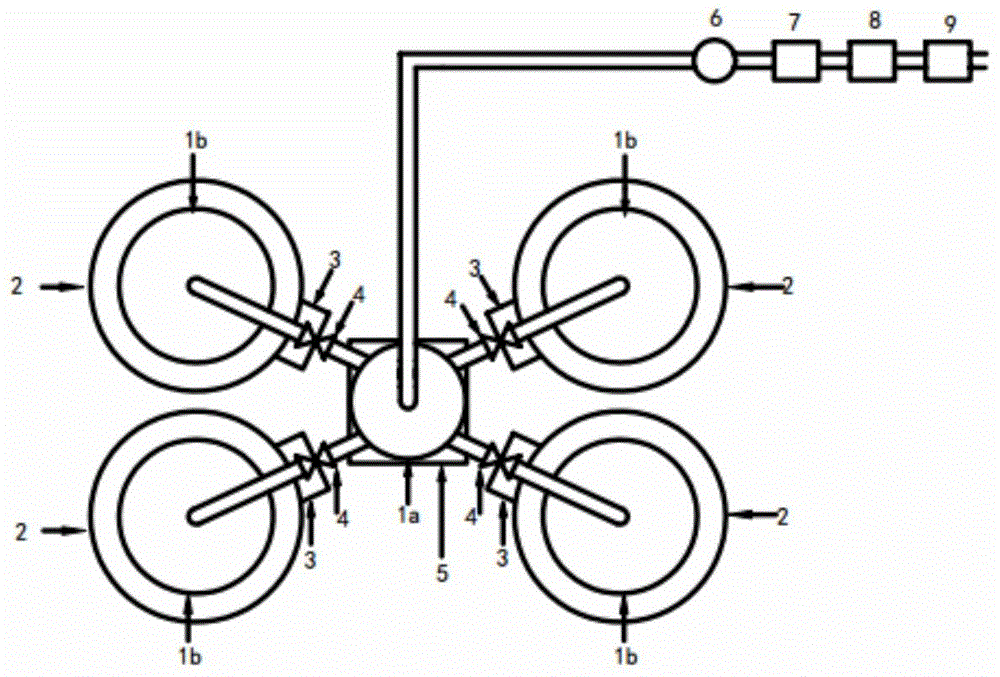

Multi-cavity continuous microwave vacuum spray drying equipment

A technology of microwave vacuum and drying equipment, which is applied in the fields of food, medicine, and chemical industry. It can solve the problems of not being able to dry different materials at the same time, not being able to work continuously, and low production efficiency. The effect of convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] The adjustment of the spraying wind speed of the equipment of the present invention is achieved by the following methods: during the drying process, if only one valve 4 corresponding to the drying chamber 2 is opened, the spraying wind speed is the full wind speed; if two drying chambers 2 are opened, the corresponding For valve 4, the wind speed in each drying chamber 2 is 1 / 2 of the full wind speed; and so on. Controlling the number of openings of the valves 4 corresponding to the drying chamber 2 can realize the adjustment of the spray wind speed. Theoretically, the number of drying chambers 2 can be unlimited, and the number of drying chambers 2 can be determined according to actual requirements.

Embodiment 2

[0054] During the drying process, when one drying chamber 2 is being dried, any other drying chamber 2 can be opened for feeding and unloading, and the drying chambers 2 are fed and unloaded in sequence to achieve continuous drying operation of the entire equipment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com