Method for underground coal gasification for gasifier channel establishment

A technology of coal gasification and gasification furnace, which is applied in coal gasification, underground mining, construction, etc., can solve the problem of success rate of connection between holes, abandoned coal mines with no economic mining value, etc., and achieve high success rate of docking and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

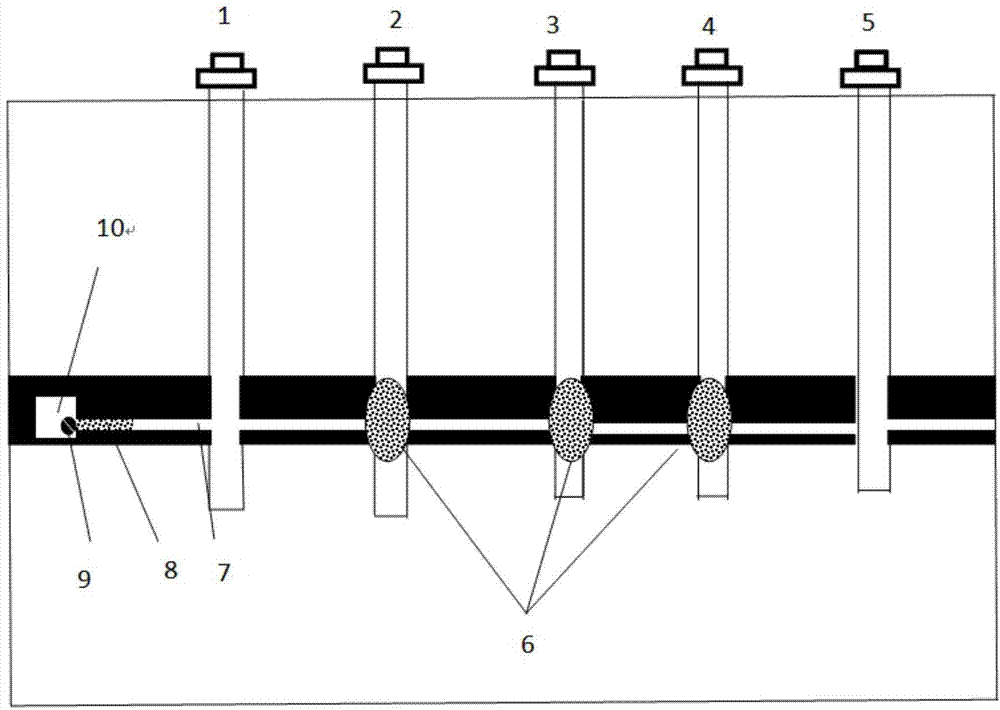

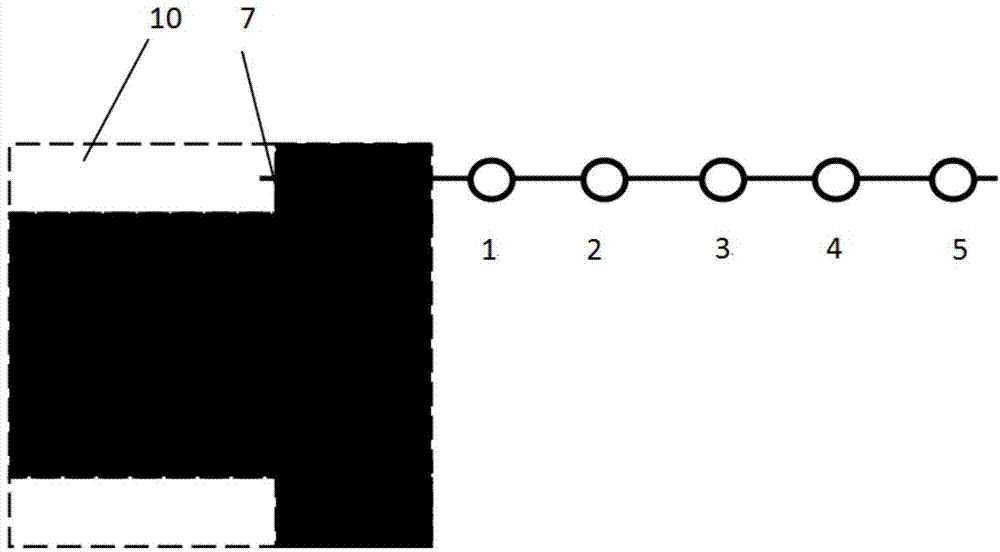

[0022] see figure 1 with figure 2 , a kind of underground coal gasification method that the present invention proposes to construct the gasifier channel, its process steps are as follows:

[0023] 1. Drill injection holes on the ground in the gasification operation area. According to the data of the drilling in the mining area and the above-mentioned actual drilling, choose a thicker and stable coal seam;

[0024] 2. Under the coal mine, use the directional follow-up drilling technology to connect the ground injection hole, and then continue drilling in the coal seam along the connection direction to form a horizontal hole gasification channel supported by a combustible casing;

[0025] 3. Use underground fracturing equipment in coal mines to implement staged fracturing operations for horizontal holes;

[0026] 4. After the fracturing operation is completed, adopt the horizontal hole sealing technology to seal the hole between the downhole drilling and the injection hole wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com