Dyeing vats with pressure accumulator

A technology of dyeing vats and equipment, applied in the field of dyeing vats, can solve problems such as accidents and deformation of dyeing vats, and achieve the effect of ensuring efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

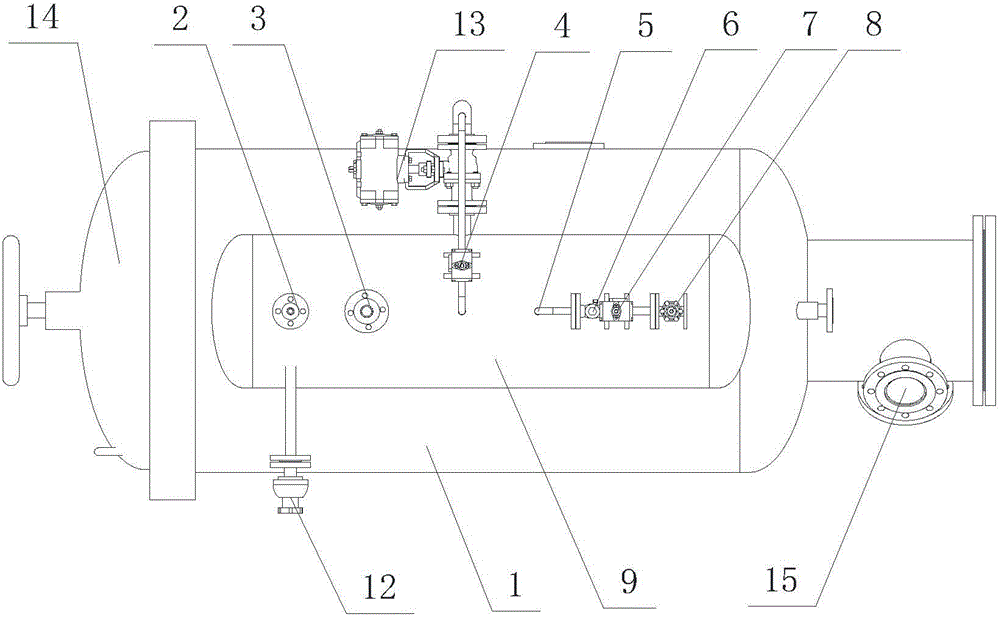

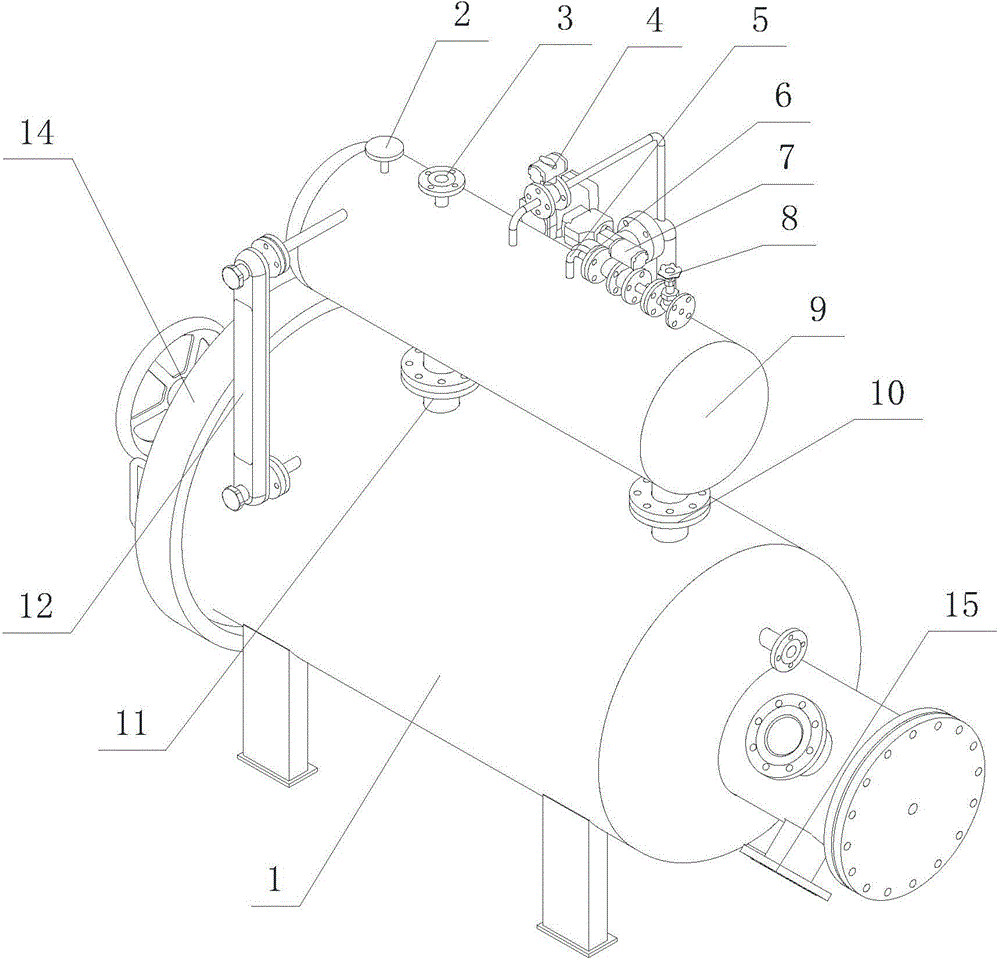

[0015] Example: see figure 1 , figure 2 with image 3 , a dyeing vat with a pressure storage device, comprising a vat 1, the vat 1 is provided with a bobbin inlet and exit door 14 and a dye solution inlet 15, a pressure gauge 2, a safety valve 3 and a degassing valve 4, and an observation dyeing vat The liquid level gauge 12 of the dye liquor height in the cylinder, the cylinder body 1 is provided with a buffer tank 9 communicating with it, the buffer tank 9 is connected with the cylinder body 1 through the exchange channel, and the pressure gauge 2, safety valve 3, off The air valves 4 are all arranged on the buffer tank 9 .

[0016] As preferably, the buffer tank 9 is also provided with a compressed air inlet 5, which is sequentially connected with a check valve 6, a pneumatic ball valve 7 and a stop valve 8; the degassing valve 4 is provided with a suction valve 13.

[0017] Preferably, the buffer tank 9 is a cylinder with spherical ends, and is horizontally arranged a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com