An automatic press molding system for the production of water glass expansion vitrified microbead lightweight insulation board

A technology of expanded vitrified microbeads and automatic pressing, applied in ceramic molding machines, manufacturing tools, supply devices, etc., can solve the problems of low degree of automation, difficult to control process parameters, low efficiency, etc., to achieve controllable compaction density, High production efficiency and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

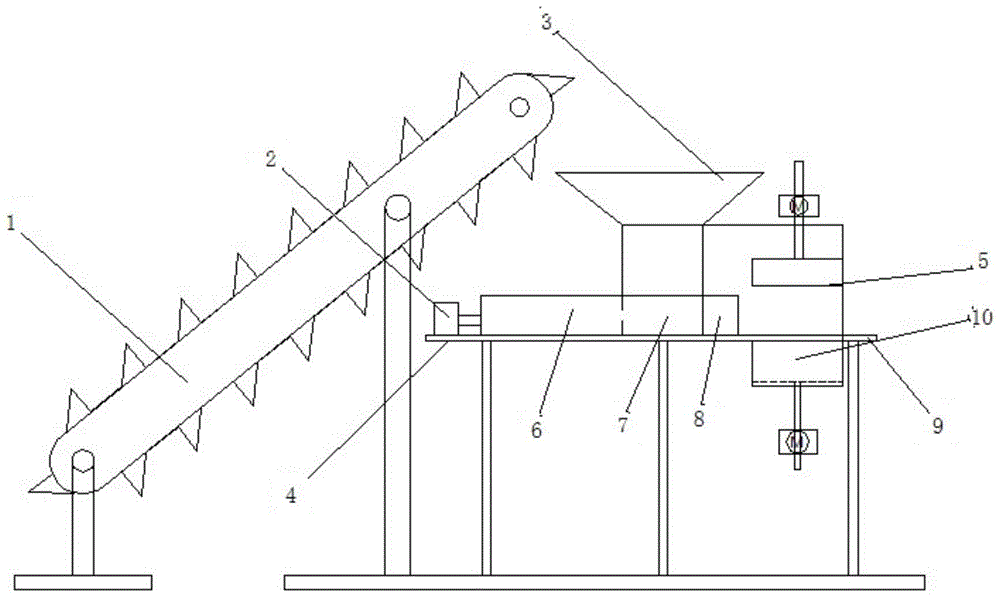

[0017] A preferred embodiment of the present invention will be described below with reference to the accompanying drawings, but it should be understood that this embodiment is only an example of the present invention, and it does not limit the protection scope of the present invention.

[0018] Such as figure 1 Shown, the automatic press forming system of the present invention, described system is used for the production of water glass expansion vitrification microbead lightweight insulation board. The system includes a material conveyor belt, a material collecting device, a mould, a heat preservation board pressurizing device, a mold up and down moving device, a bulk material and heat preservation module horizontal moving device, and the like.

[0019] figure 1 The material conveyer belt 1 in is used for supplying material to collecting hopper 3, and described material is water glass expansion vitrified microbead in this embodiment, and collecting hopper is positioned at hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com