Capsule filling device

A filling device and capsule technology, which is applied in the fields of capsule delivery, drug delivery, and pharmaceutical formulations. It can solve the problems of material leakage, inability to realize large-scale multi-row die hole filling, and complicated actions, so as to save materials and make actions simple and easy. The effect of controlling and simplifying the action process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

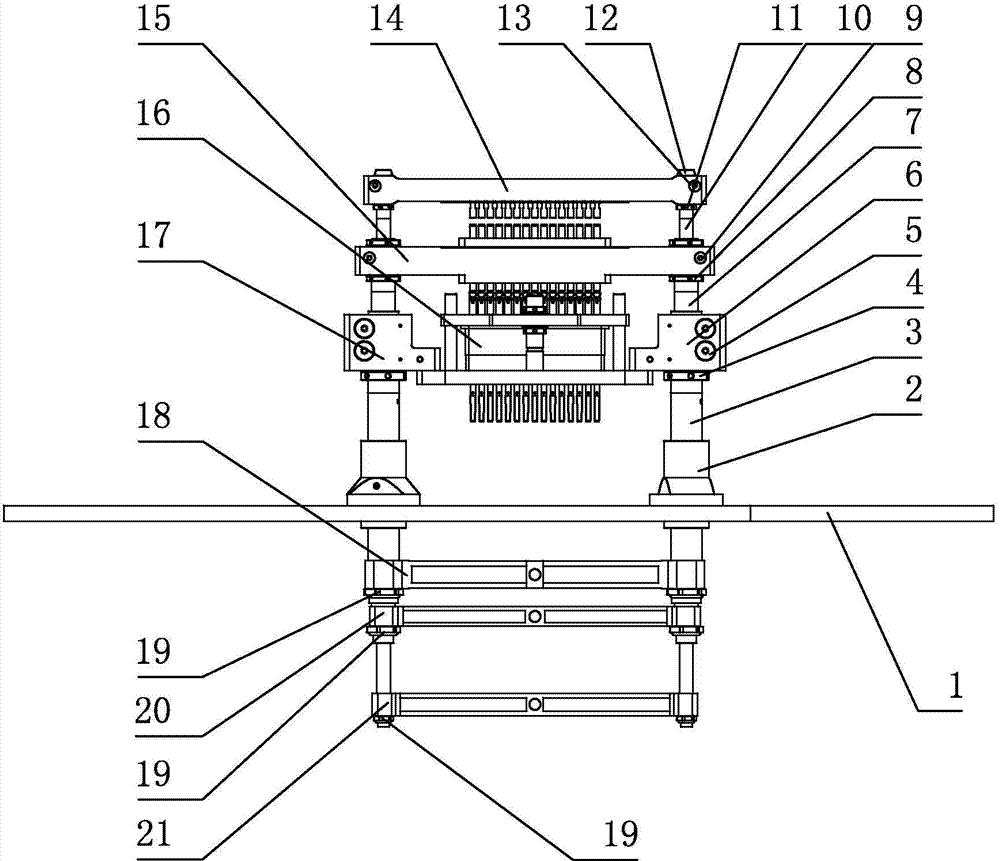

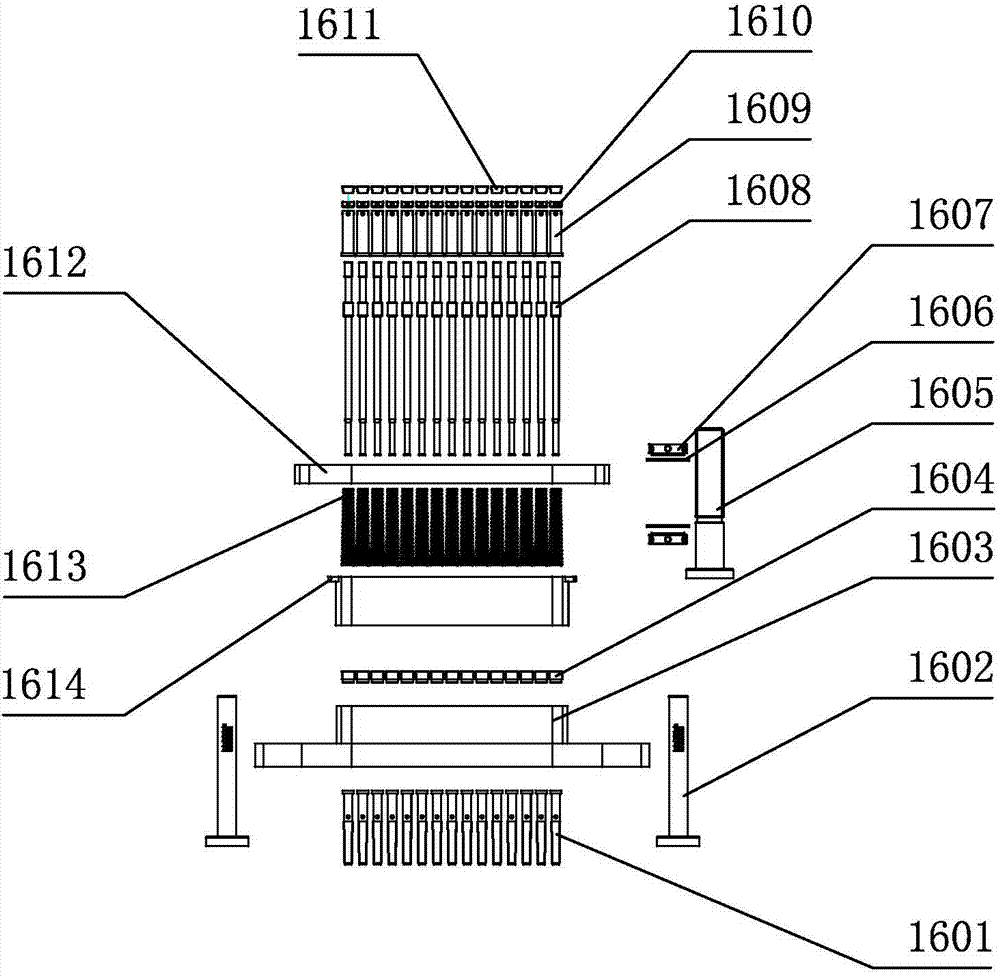

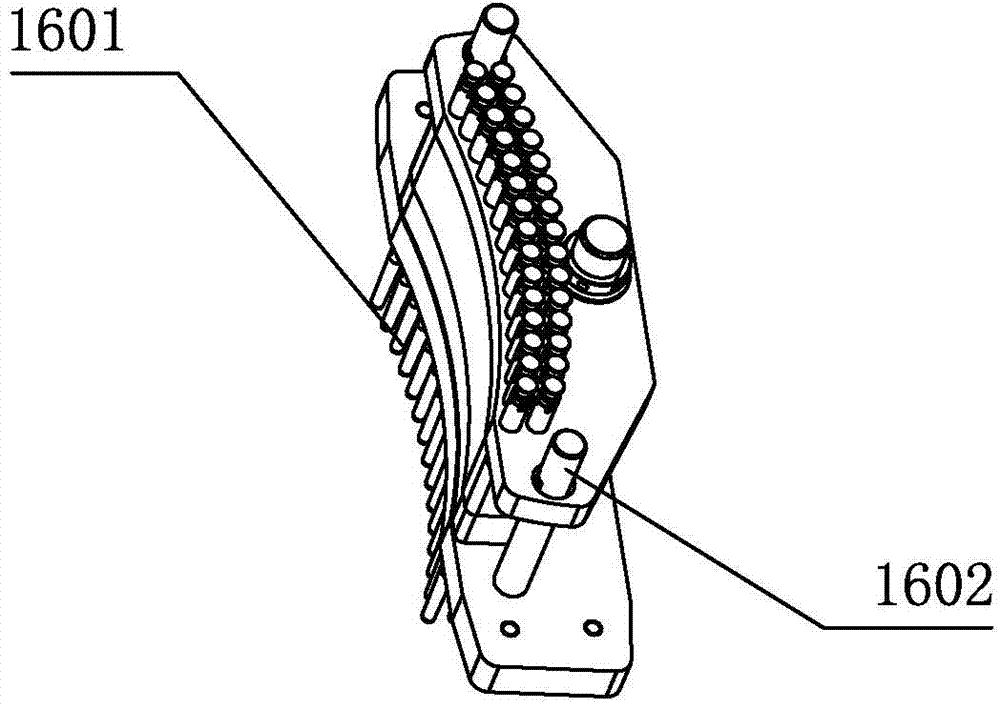

[0024] Such as figure 1 As shown, the capsule filling device includes a machine board 1, a metering device 16, a pre-compression device 15, and a discharge device 14. The machine board 1 is equipped with two sets of metering supports 2 arranged at intervals, and three-stage telescopic The shaft device, the three-stage telescopic shaft device includes the metering shaft 3, the compression shaft 7 and the discharge shaft 10, the metering shaft 3 is slidably installed in the metering support 2, the compression shaft 7 is slidably installed in the metering shaft 3, and its two ends grow out of the metering shaft. The shaft 3 and the discharge shaft 10 are slidably installed in the compression shaft 7, and the compression shaft 7 grows out from its two ends, and the discharge shaft end plug 12 is installed on the top of the discharge shaft 10. The metering d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com