A disc ditching machine

A ditching machine and disc technology, applied in the direction of excavation/covering trenches, planting methods, applications, etc., can solve the problems of non-adjustable, large vibration and impact, narrow ditching width, etc., to reduce ditching resistance, The effect of small impact vibration and large ditch width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

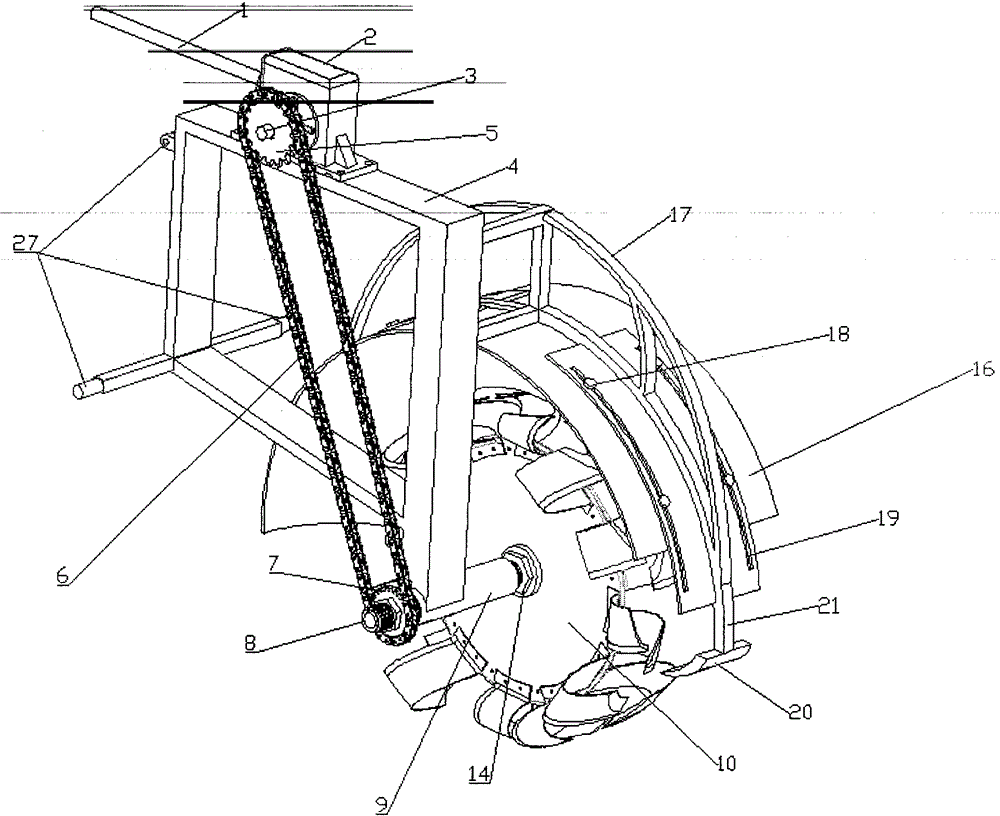

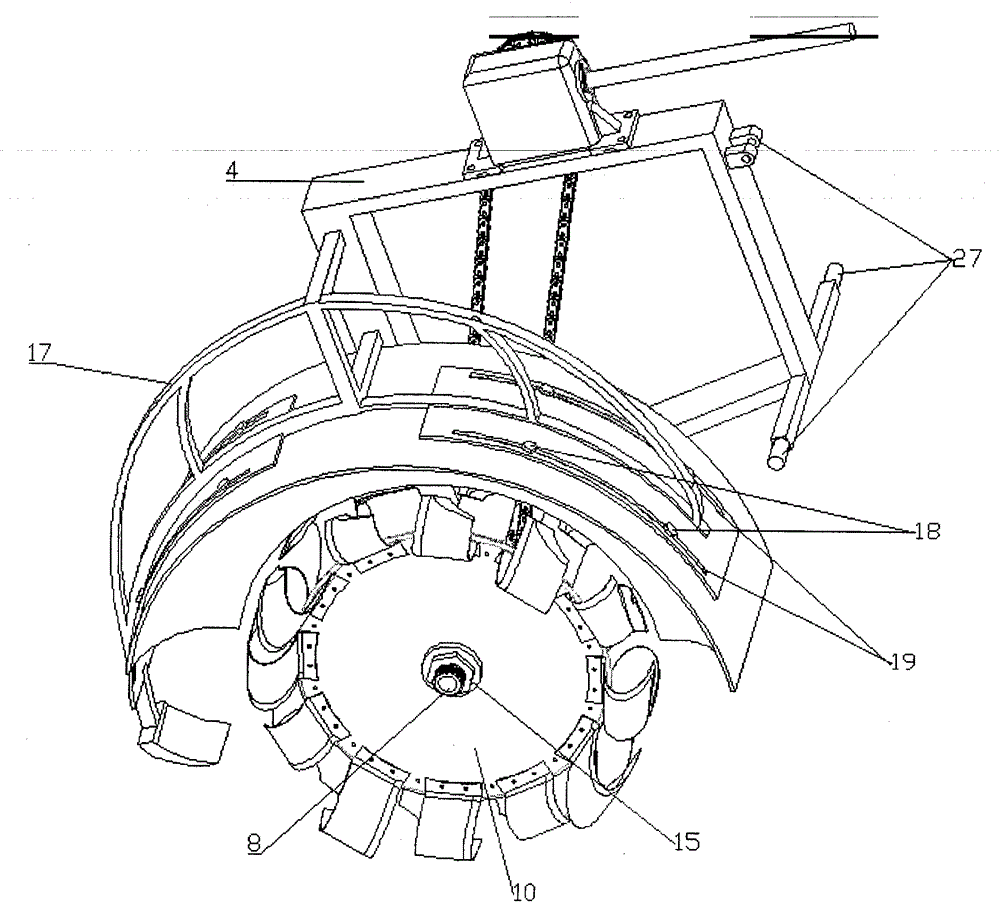

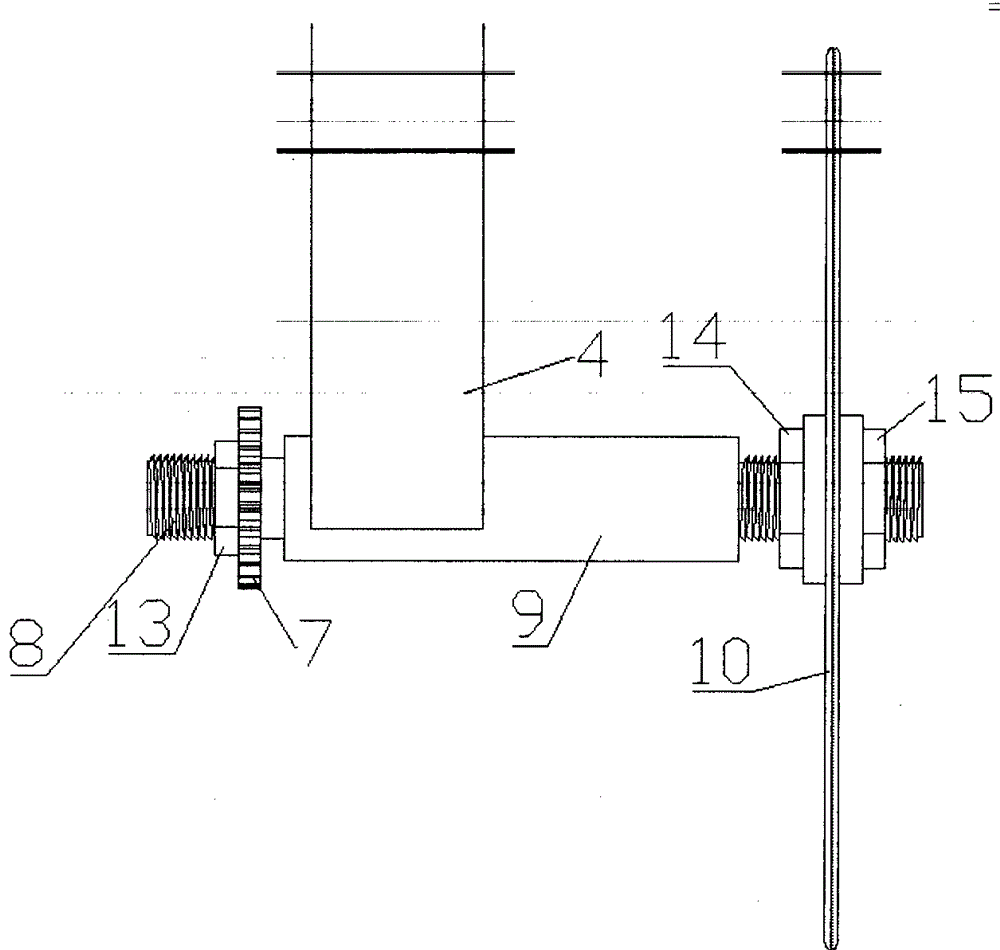

[0034] Such as Figure 1-8 As shown, the power of the tractor is transmitted to the reducer 2 through the input shaft 1 of the reducer, and then transmitted to the driven sprocket 7 by the driving sprocket 5 through the chain 6, and the driven sprocket 7 and the disc shaft 8 are keyed. , the disc shaft 8 and the disc 10 are also keyed, the driven sprocket 7 drives the disc shaft 8 to rotate, and then drives the disc 10 to rotate in the backward direction, and the disc fixed on the disc 10 is opened Knife rotates with disc 10. Width is uniformly distributed on the disc 10 in the form that the law of small ditching knife 24, middle ditching knife 23, large ditching knife 22, small ditching knife 24, middle ditching knife 23, and large ditching knife 22 changes sequentially. The three types of disc ditching knives on the side continuously excavate the soil in front. Due to the adoption of this arrangement that increases in width direction, in the process of ditching, the small t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com