Inverse magnetostrictive effect-based suspender tension sensor and tension measuring method thereof

A technology of tension sensor and inverse magnetostriction, which is applied in the measurement of the changing force of the magnetic property of the material caused by the applied stress, can solve the problems of troublesome installation of the measuring device, limited application and measurement accuracy, and achieves simple structure, Simplify the installation process and expand the effect of the application environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

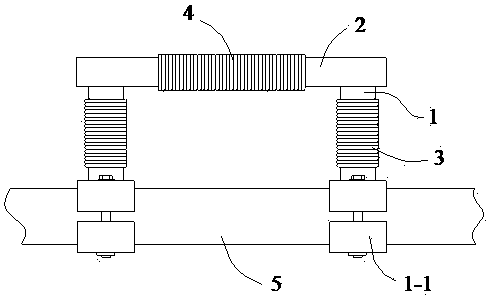

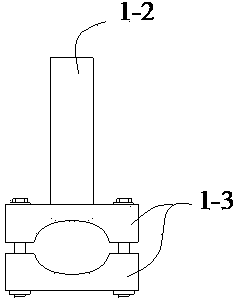

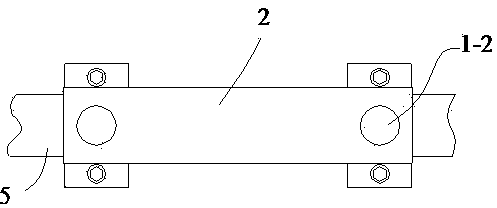

[0024] A boom tension sensor based on the inverse magnetostrictive effect, its structure is: the boom tension sensor is composed of two clamps 1, a connecting rod 2, two excitation coils 3 and a detection coil 4; one end of the clamp 1 A clamping part 1-1 is formed, and the other end of the clamp 1 forms a connecting part 1-2. The clamp 1 is fixedly connected to the suspension rod 5 to be tested through the clamping part 1-1, and the clamp 1 is connected to the connecting rod 2 through the connecting part 1-2. The excitation coil 3 is wound at the position between the connecting part 1-2 and the clamping part 1-1 on the clamp 1, and the detection coil 4 is wound at the position between the two connecting parts 1-2 on the connecting rod 2; The connecting rod 2 forms a yoke, the clamp 1 forms a magnetic pole, and the yoke, the two magnetic poles and the suspension rod 5 to be tested between the two magnetic poles form a closed magnetic circuit.

[0025] Further, the axial direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com