Optical fiber Bragg grating-based vibrating wire infrasonic wave sensor

A vibrating wire and infrasonic technology, which is used in the measurement of ultrasonic/sonic/infrasonic, instruments, and the use of wave/particle radiation. It can solve the problems of large volume, small frequency range, and low sensitivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

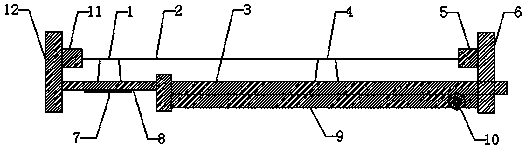

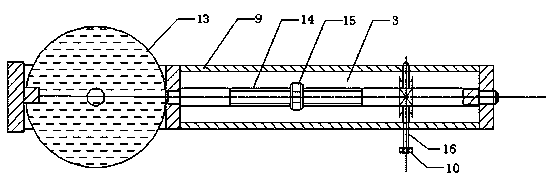

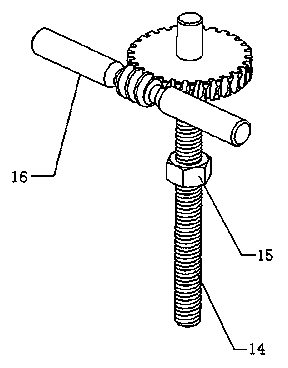

[0072] Implementation mode one: if Figures 1 to 7 As shown, the structure of the vibrating wire infrasonic sensor based on the fiber Bragg grating in this embodiment includes: string horse I1, vibrating wire 2, guide rail 3, string horse II 4 and a fixed bracket, the vibrating wire 2 is suspended and fixed on the fixed bracket, fixed There is an annular part 13 and a right side base plate 9 under the bracket installation vibrating wire 2, the annular part 13 is a circular elastic diaphragm 8, the lower surface of the elastic diaphragm 8 is pasted with a Bragg grating 7, and the right side base plate 9 is installed with a The vibrating string 2 is parallel to the guide rail 3, and the bridge I1 is fixedly installed at the center of the elastic diaphragm 8. The bridge II4 that can move along the guide rail is installed on the guide rail 3, and the vibrating string 2 is in contact with the bridge I1 and the bridge II4. The vibrating string 2 of the fixed support is fixedly conne...

Embodiment approach 2

[0073] Implementation mode two: if Figures 1 to 7 As shown, the structure of the vibrating wire infrasonic sensor based on the fiber Bragg grating in this embodiment includes: string horse I1, vibrating wire 2, guide rail 3, string horse II 4 and a fixed bracket, the vibrating wire 2 is suspended and fixed on the fixed bracket, fixed There is an annular part 13 and a right side base plate 9 under the bracket installation vibrating wire 2, the annular part 13 is a circular elastic diaphragm 8, the lower surface of the elastic diaphragm 8 is pasted with a Bragg grating 7, and the right side base plate 9 is installed with a The vibrating string 2 is parallel to the guide rail 3, and the bridge I1 is fixedly installed at the center of the elastic diaphragm 8. The bridge II4 that can move along the guide rail is installed on the guide rail 3, and the vibrating string 2 is in contact with the bridge I1 and the bridge II4. The vibrating string 2 of the fixed support is fixedly conne...

Embodiment approach 3

[0074] Implementation mode three: if Figures 1 to 7 As shown, the structure of the vibrating wire infrasonic sensor based on the fiber Bragg grating in this embodiment includes: string horse I1, vibrating wire 2, guide rail 3, string horse II 4 and a fixed bracket, the vibrating wire 2 is suspended and fixed on the fixed bracket, fixed There is an annular part 13 and a right side base plate 9 under the bracket installation vibrating wire 2, the annular part 13 is a circular elastic diaphragm 8, the lower surface of the elastic diaphragm 8 is pasted with a Bragg grating 7, and the right side base plate 9 is installed with a The vibrating string 2 is parallel to the guide rail 3, and the bridge I1 is fixedly installed at the center of the elastic diaphragm 8. The bridge II4 that can move along the guide rail is installed on the guide rail 3, and the vibrating string 2 is in contact with the bridge I1 and the bridge II4. The vibrating string 2 of the fixed support is fixedly con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com