Physical simulation testing system and method for influences of mine earthquake on coal mine underground reservoir

An underground reservoir and physical simulation technology, applied in the field of feasibility test research, can solve the problems of low accuracy of model displacement monitoring and inconvenient observation of model deformation laws, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

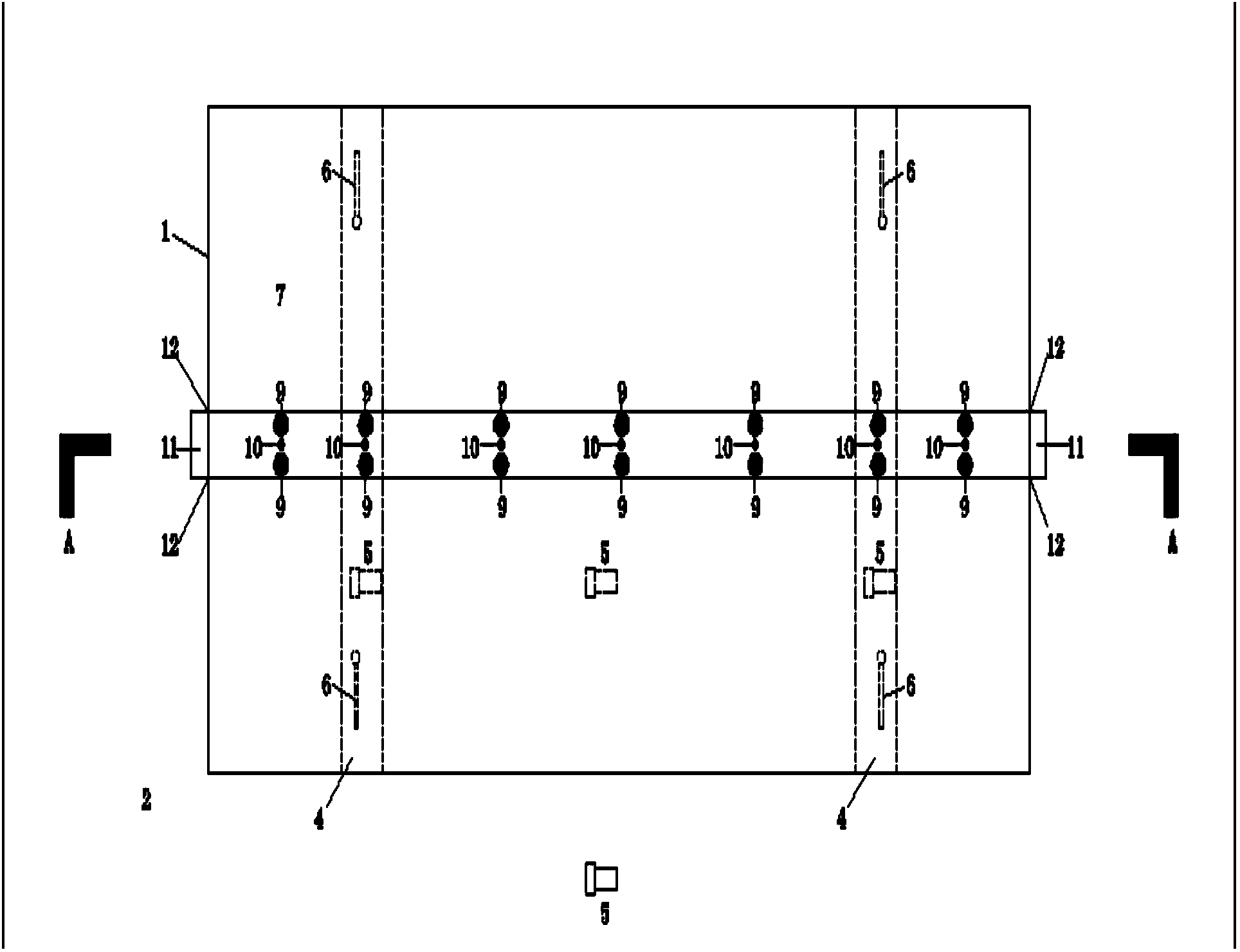

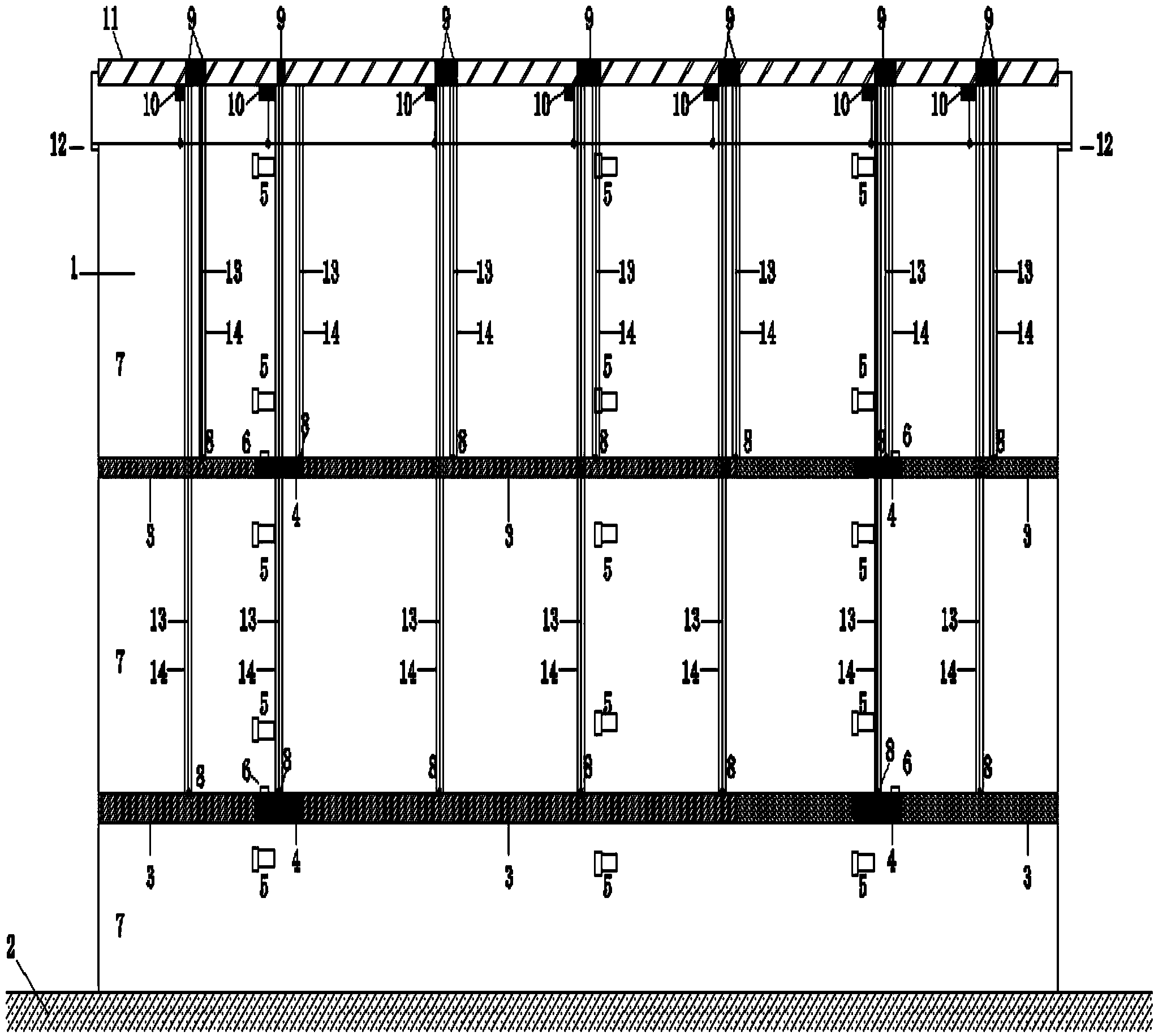

[0022] The model box 1 is fixed on the vibration table 2, and the reference beam 11 is fixed on the top of the model box 1 with screws; the model formation material 7 and the model coal pillar 4 are placed in the model box 1, and the air cushion 3 is placed on both sides of the model coal pillar 4; Three acceleration sensors 5 are respectively arranged on the upper and lower sides of the coal pillar 4 and the air cushion 3, and on the surface of the model, and one acceleration sensor 5 is fixed on the shaking table 2; a miniature pressure gauge 6 is arranged on the model coal pillar 4; The beam 11 is connected to a supporting plate 8 at the lower end by a pull wire 13 and fixed on the air cushion 3 and the model coal pillar 4. The pull wire 13 is covered with a layer of casing 14 to ensure that the pull wire can be stretched freely; the dial indicator displacement gauge 10 is fixed on the reference beam 11, and make its telescoping rod top the surface of the model.

[0023] Fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com