A new sandwich structure synthetic sleeper and its continuous pultrusion molding process

A technology of sandwich structure and pultrusion, which is applied in the direction of roads, tracks, ballast layers, etc., can solve the problems of increasing the production cost of synthetic sleepers and high product density, and achieve the goal of reducing subsequent processing links, low density and stable performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

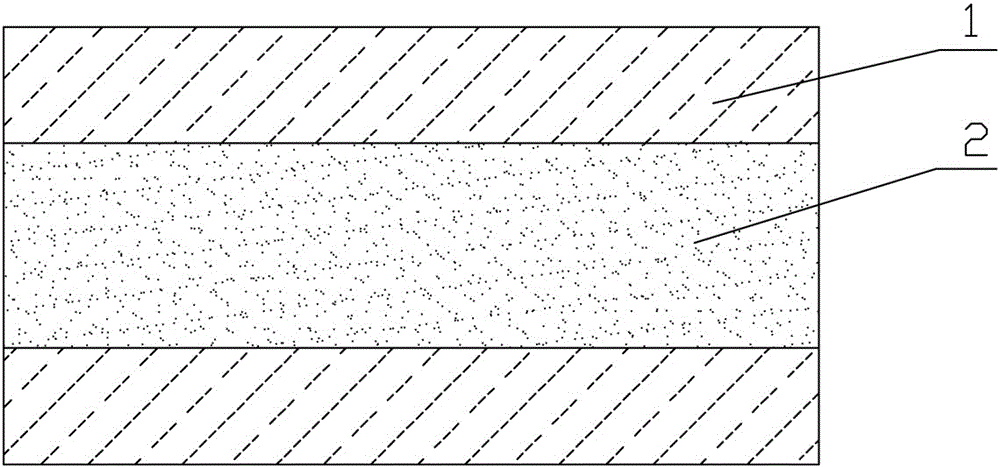

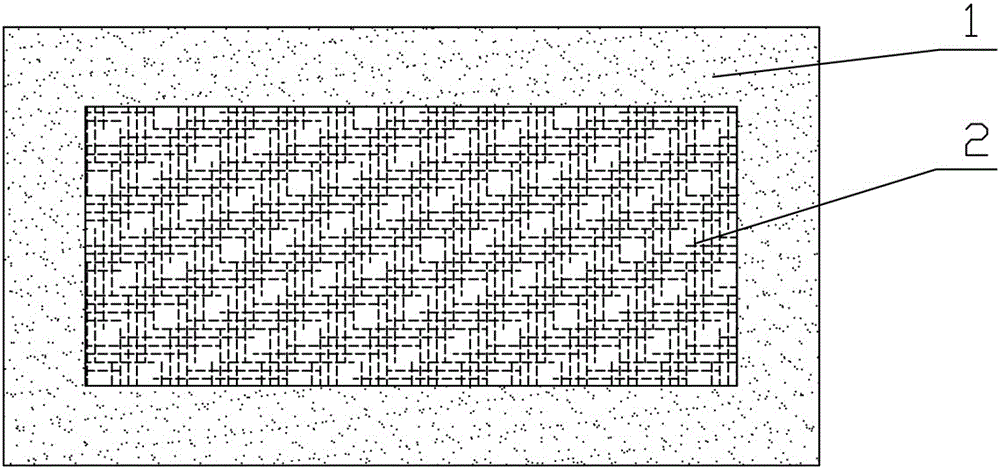

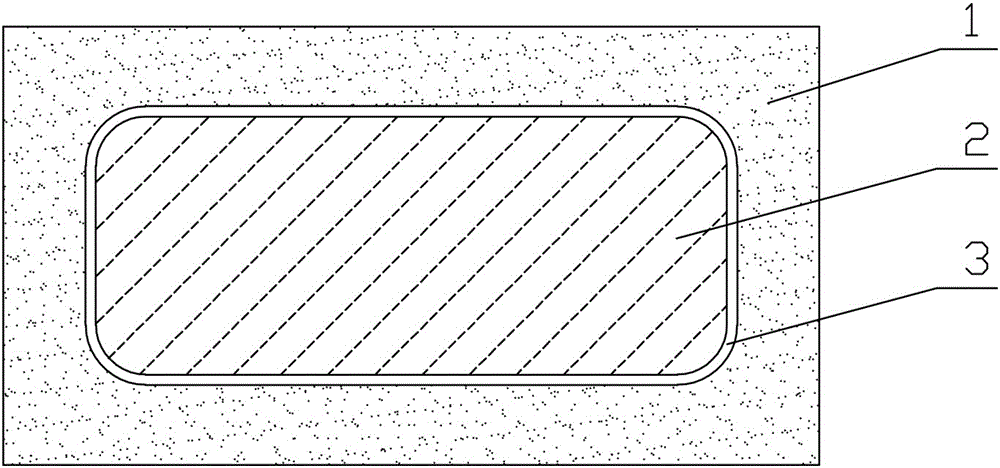

[0032] The continuous molding process of synthetic sleepers with sandwich structure includes six processes: yarn guide, foam core material conveying, foaming machine glue injection, uniform impregnation, molding, and cutting. Each process is described as follows:

[0033] (1) Yarn guide.

[0034] Guide 680 bundles of 9600Tex glass fiber roving 4 to the required section through the yarn guide frame and 2 layers of yarn collecting plates, and the running speed is 0.4m / min.

[0035] (2) Foam core delivery.

[0036] The prefabricated polyurethane foam with a density of 250kg / m3 is prefabricated into a foam core material 2 with a cross section of 150mm×100mm, and the foam core material 2 is also transported to the continuous molding device 9 for synthetic sleepers at a speed of 0.4m / min.

[0037] (3) Foaming machine injection.

[0038] Mix polyether polyol, polyether polyol, catalyst, foaming agent, flame retardant, anti-aging agent, and isocyanate in the foaming machine 5 accord...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com