Automatic car coupler control system and application thereof

An automatic control system and coupler technology, applied in railway car body parts, railway vehicle coupling accessories, railway couplings, etc., can solve the problems of difficult installation, many compressed air pipelines, and high manufacturing costs, and reduce installation. Parts and installation space, assembly and maintenance are simple, and the effect of reducing joints and pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

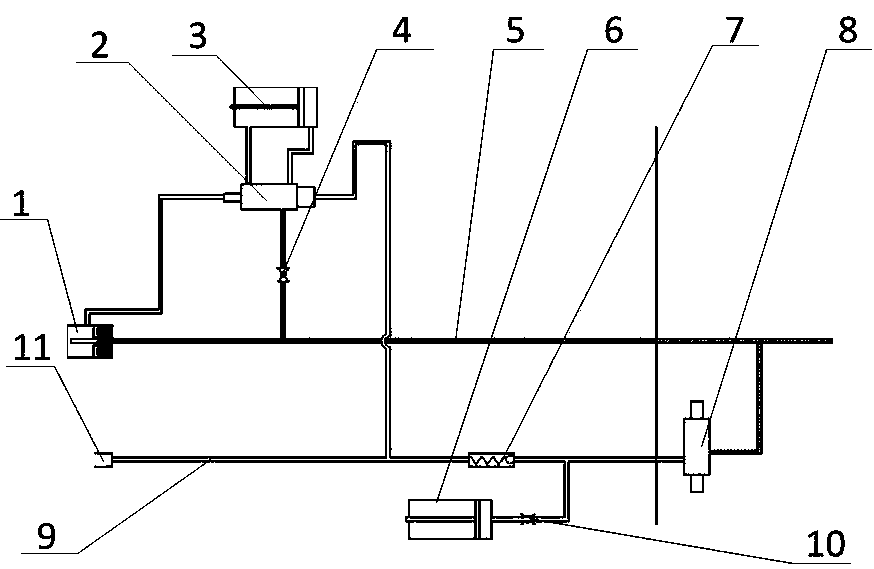

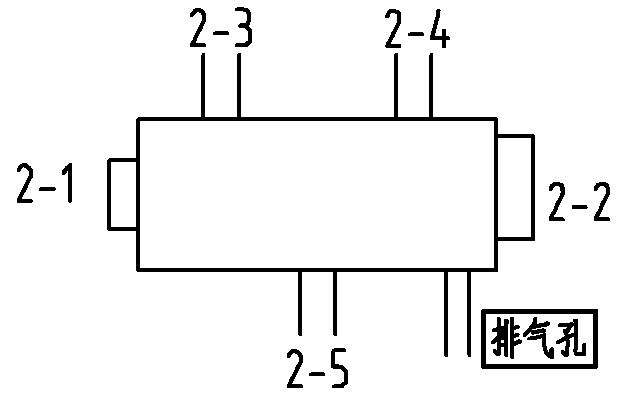

[0051] A kind of coupler automatic control system of the present embodiment, such as figure 1 , figure 2 As shown, the system includes main air pipeline 5, unhook pipeline 9, MRP main air valve 1, UC unhook air valve 11, electric hook push cylinder 3, unhook cylinder 6, air control valve 2, manual stop valve 4. One-way valve 7, throttle valve 10 and manual solenoid valve 8, the air control valve 2 is a two-position five-way valve, such as figure 2 As shown, the two-position five-way valve includes an air-controlled auxiliary control port 2-1, a main control port 2-2 of the air-controlled valve, a first working port 2-3 of the air-controlled valve, and a second port of the air-controlled valve. Working port 2-4, air inlet 2-5 and exhaust hole of the air control valve, the air inlet 2-5 of the air control valve 2 is connected to the manual shut-off valve 4 and then connected to the main air pipeline 5 phases are connected, such as Figure 5a , 5b As shown, the air outlet ...

Embodiment 2

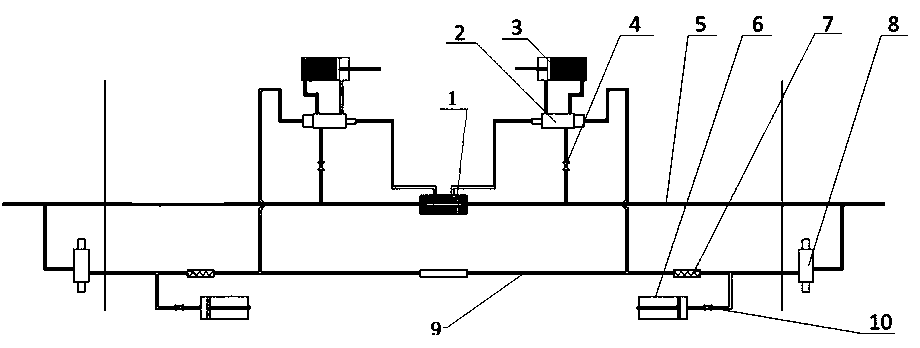

[0053] This embodiment provides the application of the coupler automatic control system in Embodiment 1 when controlling the coupler connection (structure such as image 3 shown), including the following processes:

[0054] Step 1, in the standby state, the main air pipeline 5 supplies compressed air, the MRP valve 1 is closed, there is no compressed air at the left end of the MRP valve 1, and the manual shut-off valve 4 is in a conducting state (such as Figure 5a shown), the compressed air in the main air pipeline 5 enters the air inlet 2-5 of the air control valve 2 through the manual stop valve 4, passes through the first working port 2-3, and then enters the front end of the electric hook push cylinder 3, Keep the electric hook retracted, and the two couplers to be connected contain the same system and are also in the same state. The two systems are connected through the MRP valve 1 and the UC uncoupling air valve;

[0055] Step 2, as the coupler completes the connection...

Embodiment 3

[0059] This embodiment provides the application of the automatic coupler control system of Embodiment 1 when controlling the uncoupling of the coupler (structure such as image 3 shown), including the following processes:

[0060] Step 1, press the manual solenoid valve 8, the compressed air in the main air pipeline 5 enters the uncoupling pipeline 9 through the air inlet and the air outlet of the manual solenoid valve 8;

[0061] Step 2, the compressed air entering the uncoupling pipeline 9 is divided into two paths, one path passes through the throttle valve 10 and enters the uncoupling cylinder 6 to promote mechanical uncoupling, one path passes through the one-way valve 7 and then is divided into two paths, one of which enters the The main control terminal 2-2 of the air control valve 2 controls the reversing of the air control valve 2, and two of them enter the UC unhook air valve 11, and the compressed air fed into the unhook pipeline 9 enters the docking through the UC ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com