Inert gas internal-relaxation self-repair tyre

An inert gas, relaxation technology, used in tire parts, transportation and packaging, vehicle parts, etc., can solve problems such as difficult self-rescue, poor performance of punctured shrinkage holes, and poor quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

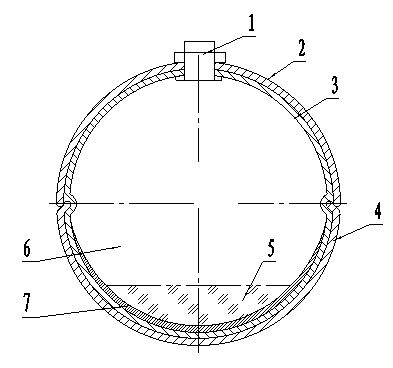

[0009] Below in conjunction with Fig. 1, describe in detail the specific work situation that the present invention proposes, from figure 1 In the middle, the relaxation layer (7) is added to the inner tube (3) by relaxation, the relaxation layer (7) reaches the standard when the air is filled, the relaxation layer (7) does not stretch, has good elasticity, and ensures the relaxation of the inner tube (3) at the contact angle The loose layer (7) does not stretch, and has the ability to shrink the hole into a seam after being stabbed, and the self-replenishing liquid (5) can seal the air leakage seam, and at the same time fill in the inert gas (6) to make the tire self-replenishing ( 5) It does not deteriorate, and can use a variety of glue solutions in the market as self-replenishment fluid (5). Inert gas (6) does not react with its glue solution. Therefore, self-replenishment fluid (5) only reacts at the overflow edge of the punctured hole, ensuring Self-replenishing liquid (5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com