A kind of preparation method of essential oil microcapsule

A technology of microcapsules and essential oils, applied in microcapsule preparations, preparation of microspheres, essential oils/fragrances, etc., can solve the problem of damage, difficulty in ensuring the utilization rate and quality of essential oils, loss of volatile components in essential oils, heat-sensitive flavor substances, etc. problem, achieve the effect of avoiding damage, improving storage stability, and improving release effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

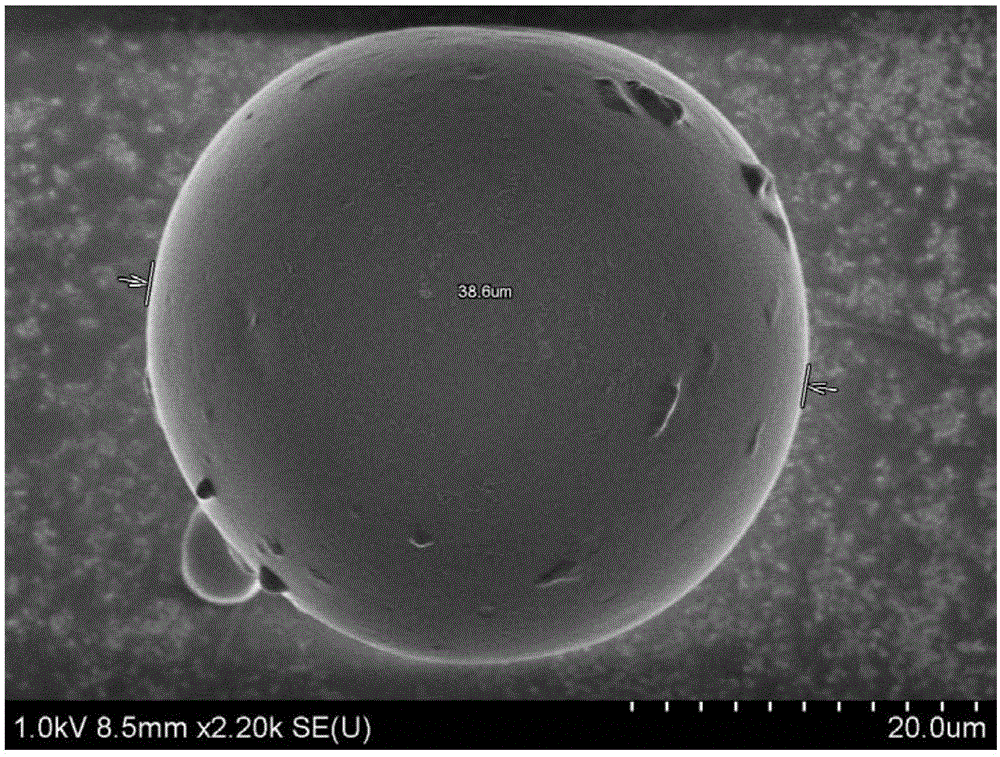

Image

Examples

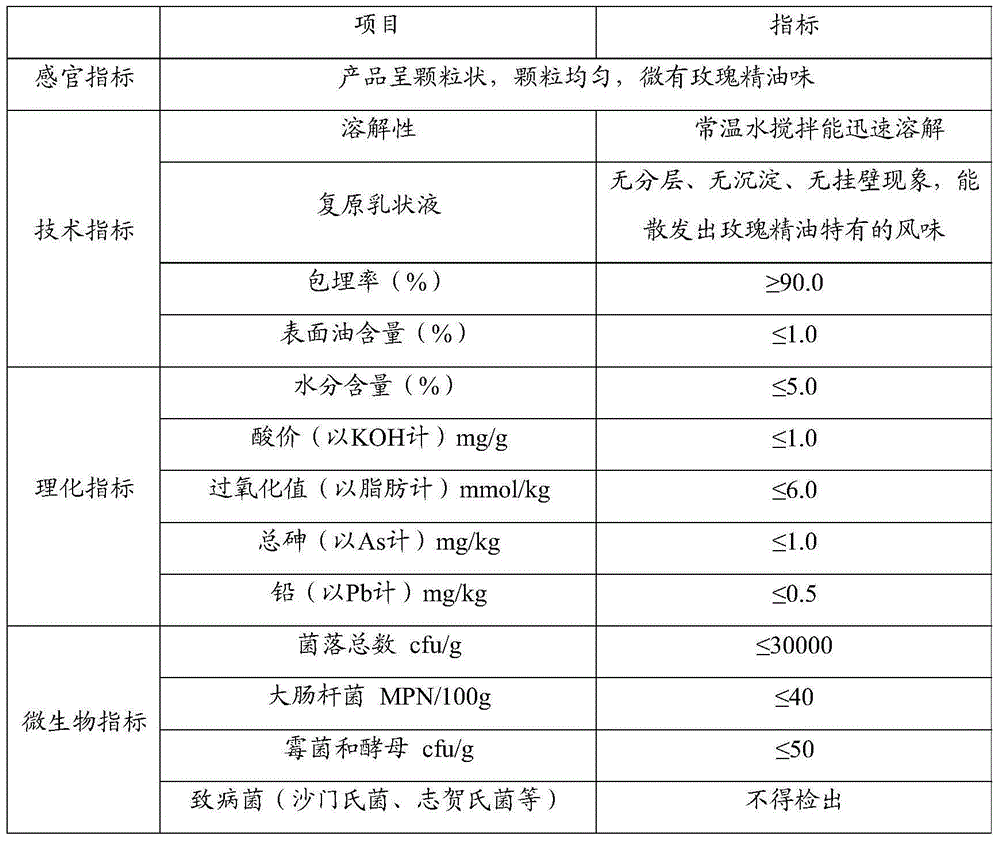

Embodiment 1

[0025] Prepare a kind of rose essential oil microcapsule, and its concrete steps are as follows:

[0026] 1) Weigh 7.3kg of maltodextrin and 1.5kg of modified starch into a hot and cold cylinder, add 10kg of pure water, stir at 85°C at 50rpm / min until completely dissolved and uniform, and prepare an aqueous phase liquid;

[0027] 2) Weigh 1kg of rose essential oil and put it in another hot and cold cylinder, stir at 50rpm / min at 45°C, then weigh 0.14kg of monoglyceride and 0.06kg of sodium stearoyl lactylate into it, continue to keep warm and stir until completely Uniform, prepared into an oil phase liquid;

[0028] 3) Use a peristaltic pump to pump the oil phase liquid into the water phase liquid at a rate of 50mL / min, and keep stirring at 50rpm / min at 45°C for 30min to obtain an emulsion with a solid content of 50% (wt%);

[0029] 4) Use a valve-type high-pressure homogenizer to emulsify and homogenize the above emulsion, and circulate and homogenize twice under a pressure ...

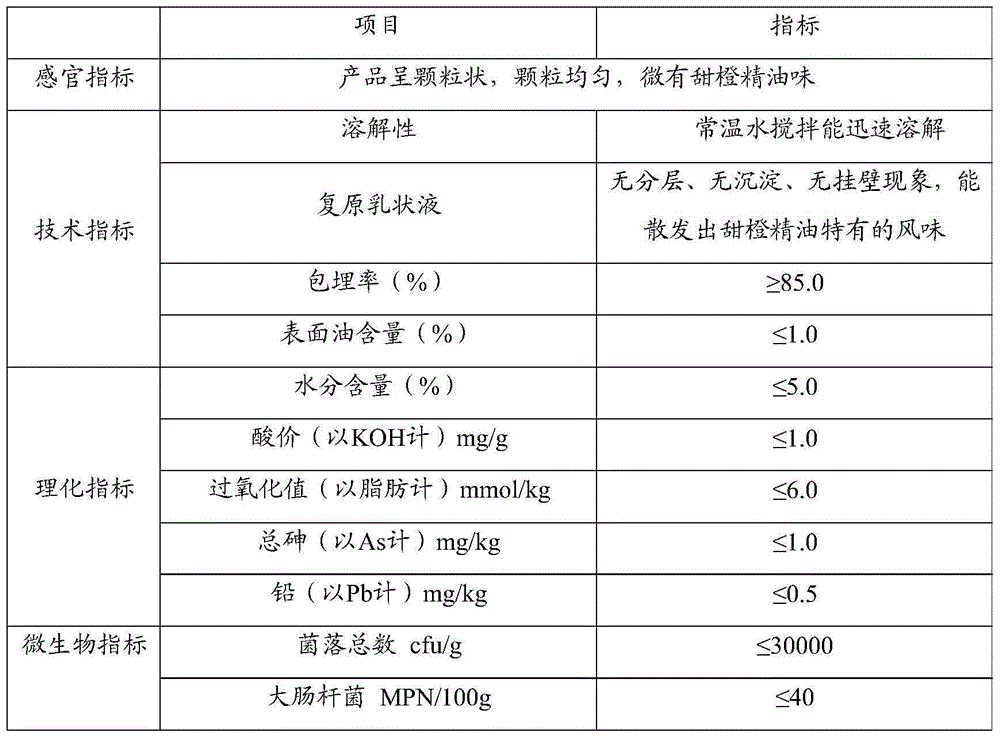

Embodiment 2

[0035] Prepare a kind of sweet orange essential oil microcapsule, its concrete steps are as follows:

[0036] 1) Weigh 6.5kg of maltose syrup and 1.3kg of modified starch into a hot and cold cylinder, add 15kg of pure water, stir at 85°C at 50rpm / min until completely dissolved and uniform, and prepare an aqueous phase liquid;

[0037] 2) Weigh 2kg of sweet orange essential oil and place it in another hot and cold cylinder, stir at 50°C at 50rpm / min, then weigh 0.15kg of monoglyceride and 0.05kg of sodium stearoyl lactylate into it, and continue to keep warm and stir until Completely uniform, prepared into an oil phase liquid;

[0038] 3) Use a peristaltic pump to pump the oil phase liquid into the water phase liquid at a rate of 100mL / min, and keep stirring at 50°C for 30min at 50rpm / min to obtain an emulsion with a solid content of 40%;

[0039] 4) Use a valve-type high-pressure homogenizer to emulsify and homogenize the above emulsion, and circulate and homogenize twice und...

Embodiment 3

[0046] Prepare a kind of agarwood essential oil microcapsule, and its specific steps are as follows:

[0047] 1) Weigh 7.7kg of maltose syrup and 1.6kg of modified starch into a hot and cold cylinder, add 10kg of pure water, stir at 85°C at 50rpm / min until completely dissolved and uniform, and prepare an aqueous phase liquid;

[0048] 2) Weigh 0.7kg of agarwood essential oil and place it in another hot and cold cylinder, stir at 45°C at 50rpm / min, then weigh 0.14kg of monoglyceride and 0.06kg of sodium stearoyl lactylate into it, and continue to keep warm and stir until Completely uniform, prepared into an oil phase liquid;

[0049]3) Use a peristaltic pump to pump the oil phase liquid into the water phase liquid at a rate of 10 mL / min, and keep stirring at 50 rpm / min at 45 °C for 30 min to obtain an emulsion with a solid content of 50% (wt%);

[0050] 4) Use a valve-type high-pressure homogenizer to emulsify and homogenize the above emulsion, and circulate and homogenize twi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com