Combustion apparatus for aluminium section long bar hot shearing furnace

A technology of combustion device and thermal shear furnace, which is applied to combustion equipment, furnaces, furnace types, etc., can solve problems such as shortening the service life of equipment, environmental pollution, and impact on profile quality, saving costs and energy, ensuring service life, and protecting effects of the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing:

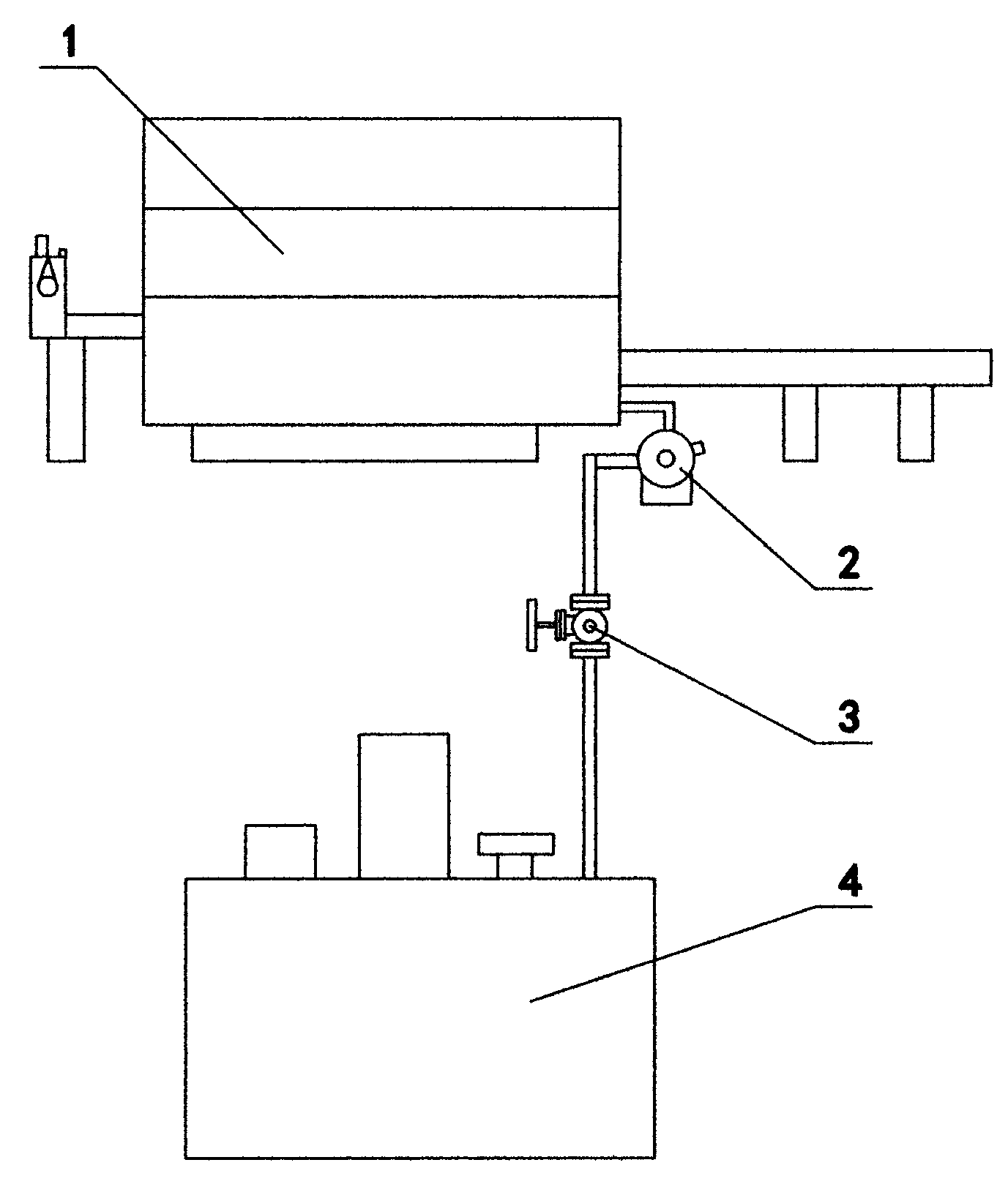

[0015] Such as figure 1 As shown, the combustion device used for the long rod hot shear furnace of aluminum profiles includes the long rod hot shear furnace 1, and the combustion port corresponding to the long rod hot shear furnace 1 is provided with a natural gas burner 2, corresponding to the air inlet of the natural gas burner 2 A pressure regulating storage station 4 is connected through a pipeline, and a pressure regulating valve 3 is installed on the pipeline between the natural gas burner 2 and the pressure regulating storage station 4 .

[0016] In this embodiment, the pressure regulating valve 3 is a pneumatic pressure regulating valve, and in practical application, the pressure regulating valve 3 is a hydraulic pressure regulating valve.

[0017] In the application process, the compressed natural gas is first stored in the pressure regulating storage station 4. W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com