Blank and bottle fetching device of bottle blowing machine

A technology of blow molding machine and swing support, which is applied in the field of preform and bottle taking devices, which can solve the problems of difficulty in ensuring accuracy, high assembly times, and high cost, and achieve stability and accuracy, simple height adjustment, and extended service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below through specific examples.

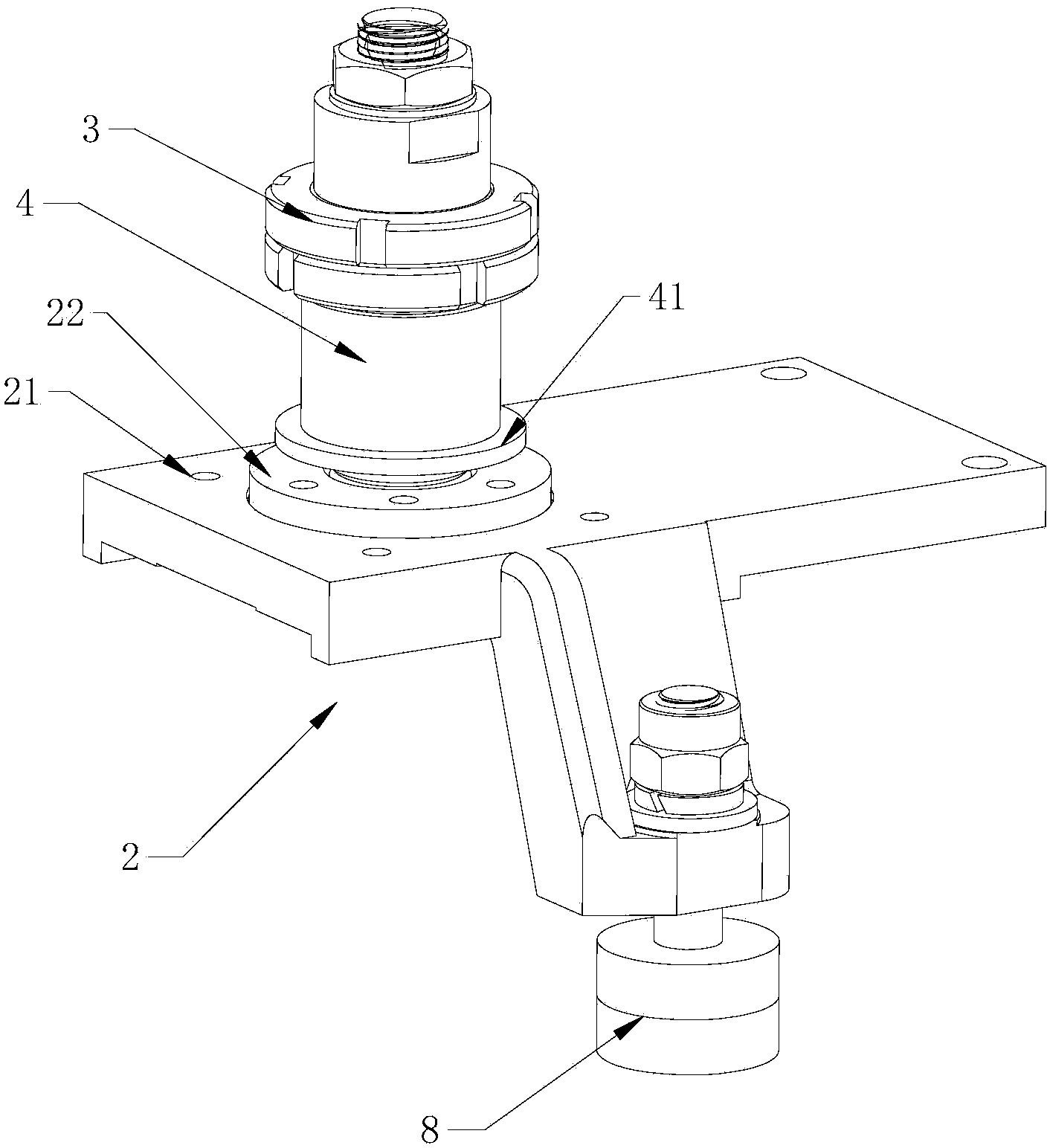

[0016] Such as figure 1 , 2 As shown, a blow molding machine preform and bottle taking device includes a support plate 1 fixed on the blow molding machine, a swing support seat 2 rotatably mounted on the support plate 1, and a swing support seat 2 mounted on the swing support seat 2 through a guide rail 5. The clamp assembly 6 is fixed on the front end of the guide rail 5; the sliding direction of the clamp assembly 6 is perpendicular to the swing center of the swing support base 2; the clamp assembly 6 includes a clamp mounting base and two mutual Cooperate with the clamp half body that is installed on the clamp mounting seat to swing; the clamp half body is provided with a contraction spring that acts on the clamp half body to make it fold.

[0017] The frame of the bottle blowing machine is rotatably equipped with a force applying cam 9, which is provided with a swing conto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com