Isostatic pressing ceramic tile die

An isostatic pressing, ceramic tile technology, applied in the direction of molds, mold auxiliary parts, manufacturing tools, etc., can solve the problems of uneven pressure of bricks, uneven density of bricks, rubber layer and template falling off, to ensure the effect of isostatic pressing, The effect of ensuring sealing and not easy to leak oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

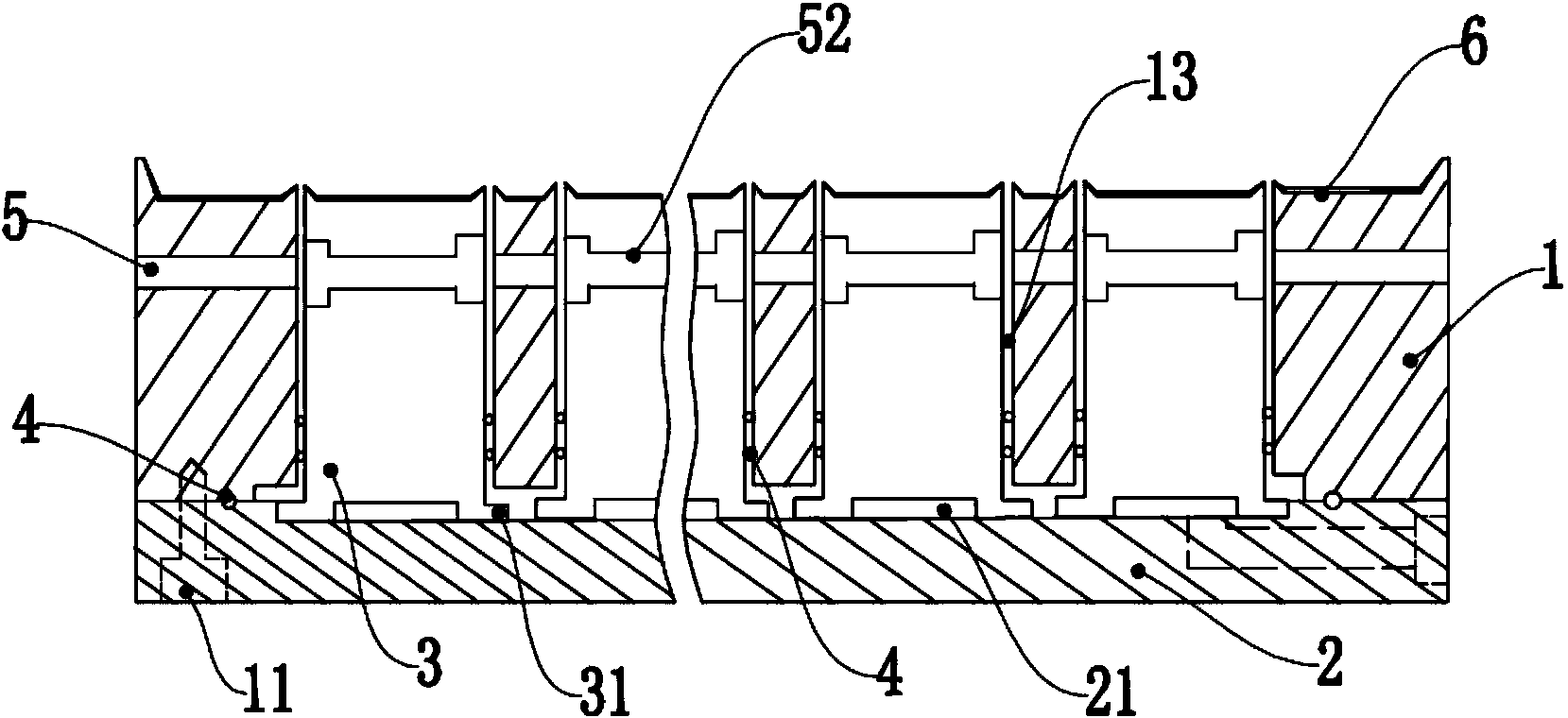

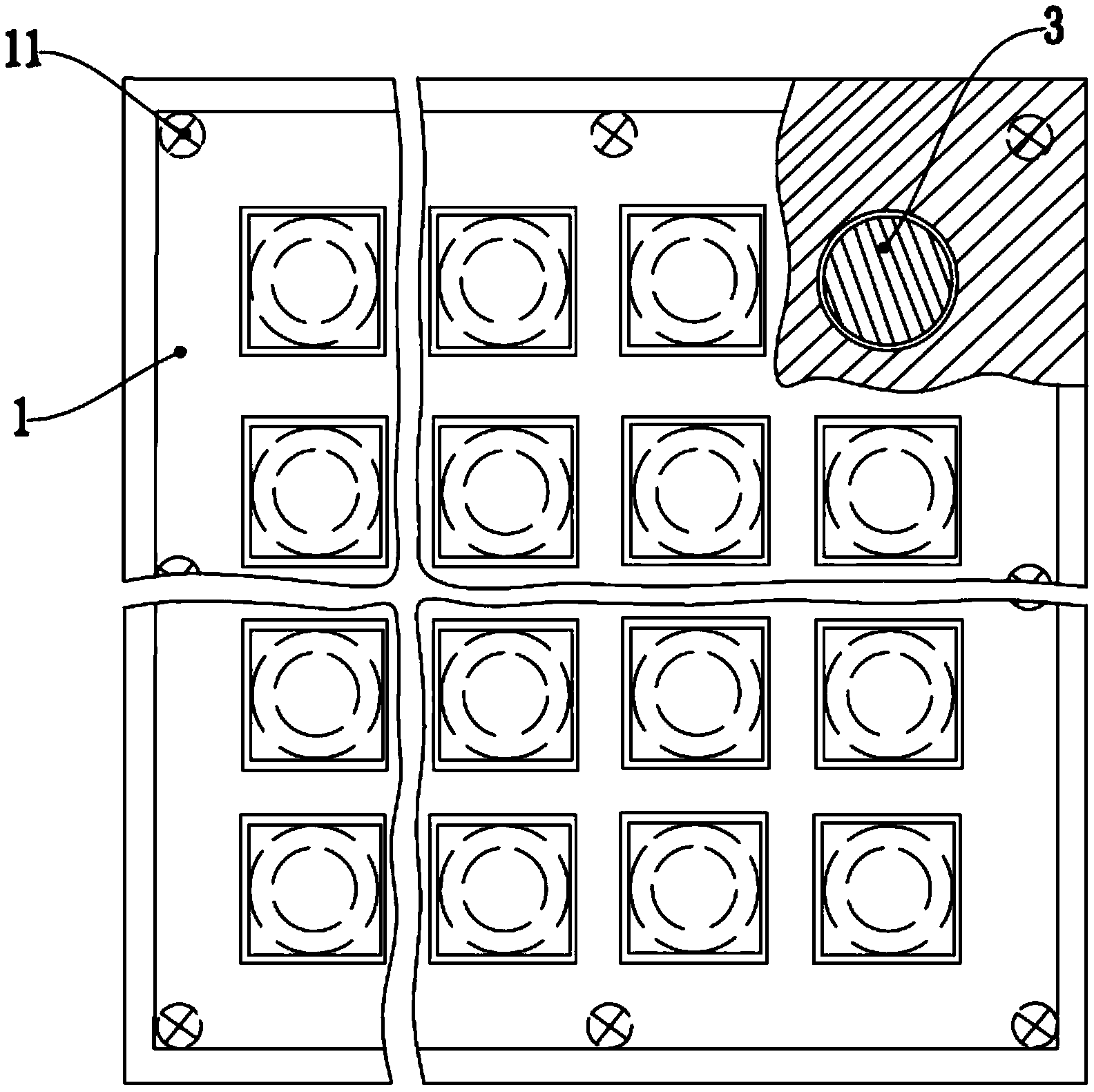

[0024] An isostatic tile mold, comprising an upper mold 1 and a lower mold 2;

[0025] The upper die 1 is provided with a plurality of through holes 13, each of the through holes 13 is provided with a piston rod 3 that can reciprocate and float in the through hole 13, and the connection between the through hole 13 and the piston rod 3 There is a gap between activities;

[0026] The periphery of the lower mold 2 is connected with the upper mold 1 by screws 11, and an oil chamber 21 is arranged between the lower mold 2, the piston rod 3 and the upper mold 1;

[0027] The end of the piston rod 3 is provided with a block 31, the block 31 is located in the oil chamber 21 and limits the floating range of the piston rod 3 in the through hole 13;

[0028] A sealing ring 4 is provided on the circumference ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com