Method for manufacturing thin-walled metal hemispherical shell with spigot

A metal material and manufacturing method technology, which is applied in the field of thin-walled metal material hemispherical shell manufacturing, can solve the problems of difficult forming, the surface quality is difficult to meet the use requirements, etc., and achieves the effect of good wall thickness consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

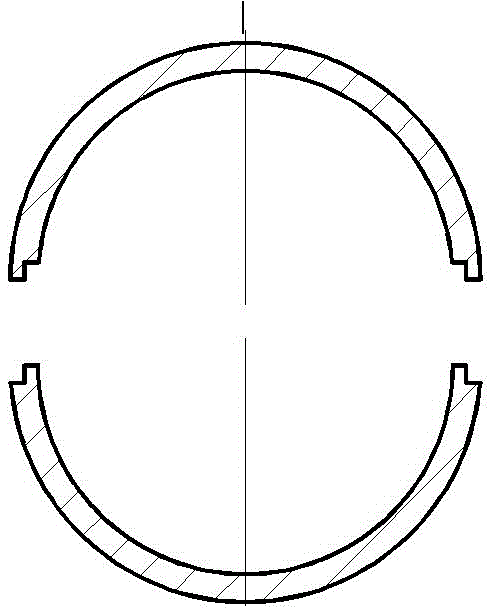

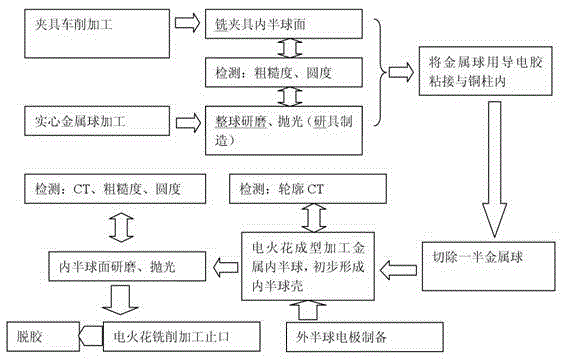

[0030] figure 1 It is a structural schematic diagram of a metal hemispherical shell with a seam in the present invention, figure 2 It is a process flow diagram of the thin-walled metal hemispherical shell with spigot in the present invention. from figure 1 , 2 It can be seen from the figure that a tungsten hemispherical shell with a diameter of about 3 mm and a wall thickness of (100-200) μm is manufactured by using a method for manufacturing a thin-walled metal hemispherical shell with a stopper of the present invention. The detailed preparation process is as follows: roughly machining a solid tungsten ball with a diameter of about 3mm, and polishing the surface of the ball into a mirror surface through a four-axis full ball mill. The grinding process parameters are as follows: grinding abrasive: diamond; particle size: W1; Pressure: (100~150) g; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| Circularity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com