Anti-loose elastic welding cable quick connect device

A welding cable, quick connection technology, applied in the direction of two-part connection device, parts of the connection device, connection, etc., can solve problems such as fire hazard, user inconvenience, burning candles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

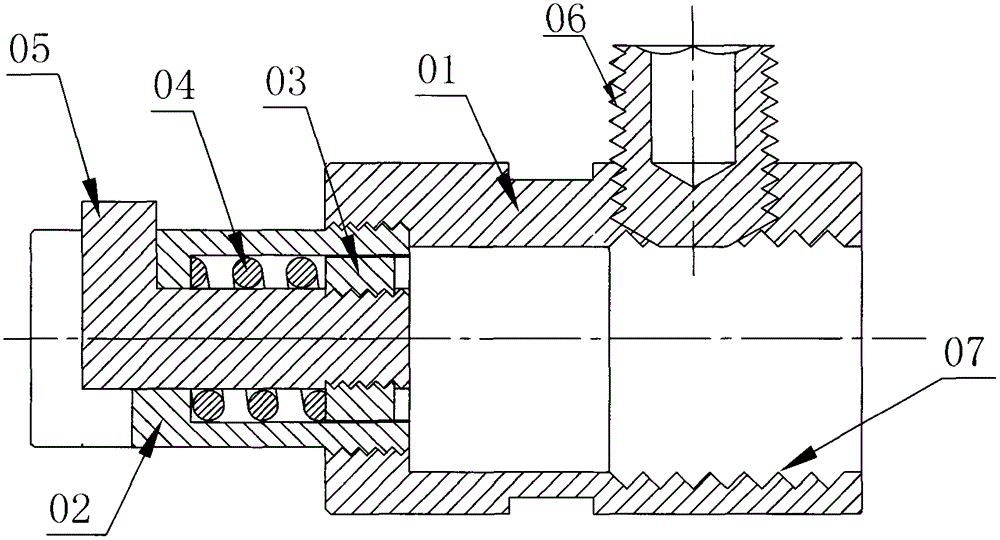

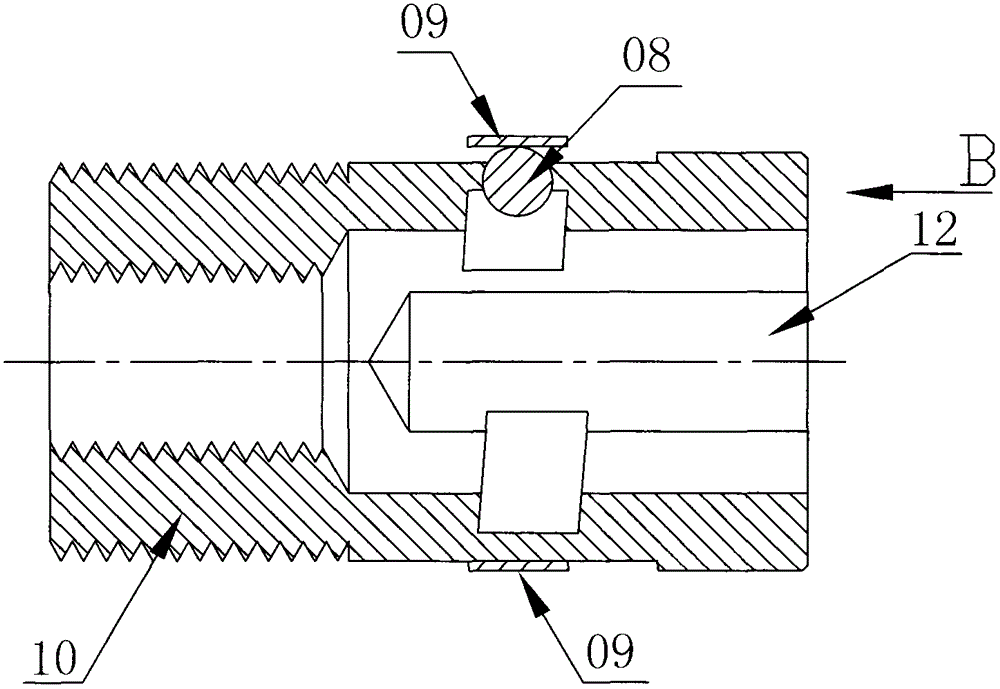

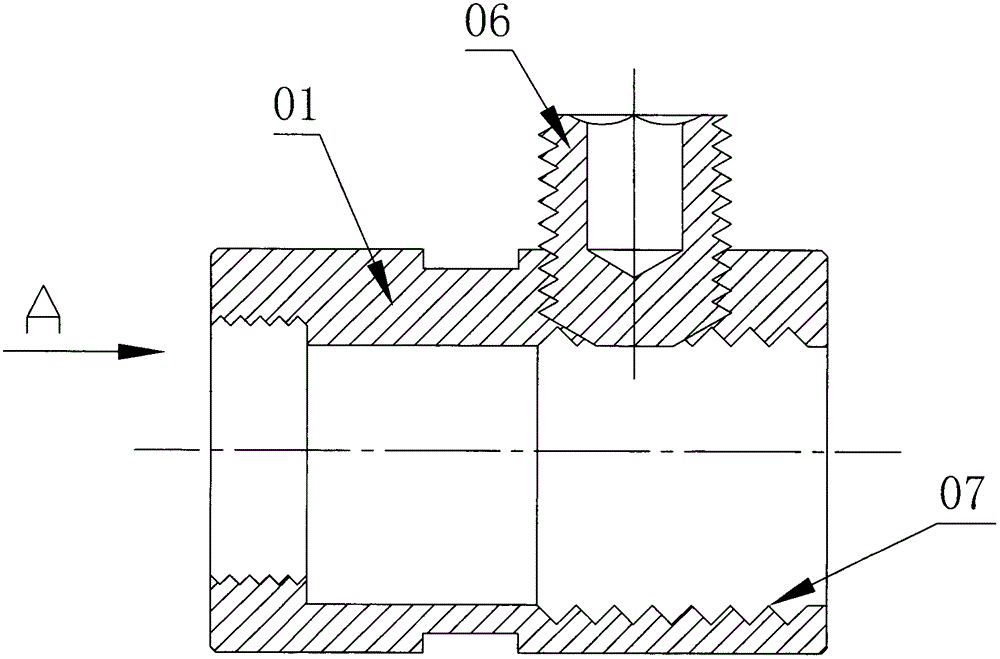

[0018] In the anti-loose elastic welding cable quick connection device of the present invention, the male plug is equipped with a spring and a chuck that moves along the axis under the action of the spring; the connecting rod of the male plug is provided with a bidirectional opening balance guide groove or It is a one-way opening balance guide groove, and the length of the upper and lower openings of the two-way opening balance guide groove can be the same or different; the friction surface between the card head and the card groove is arc-shaped or V-shaped; the cable receiving hole described The inner surface of the V-shaped groove is provided with a V-shaped groove. The angle of the V-shaped groove is between 1-179 degrees. , the sewage discharge groove has one, or more; said limit self-locking device is a movable ball controlled by the force of the elastic steel plate on the slot.

[0019] The anti-loose elastic welding cable quick connection device of the present invention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com