Welding clamping mechanism of box type automobile exhaust purifier

A technology of automobile exhaust and purifier, which is applied in the direction of welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of manpower consumption, working hours, large gap at the positioning position, and inability to fix the end cover, etc., so as to save working hours, The effect of reducing deformation and reducing the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

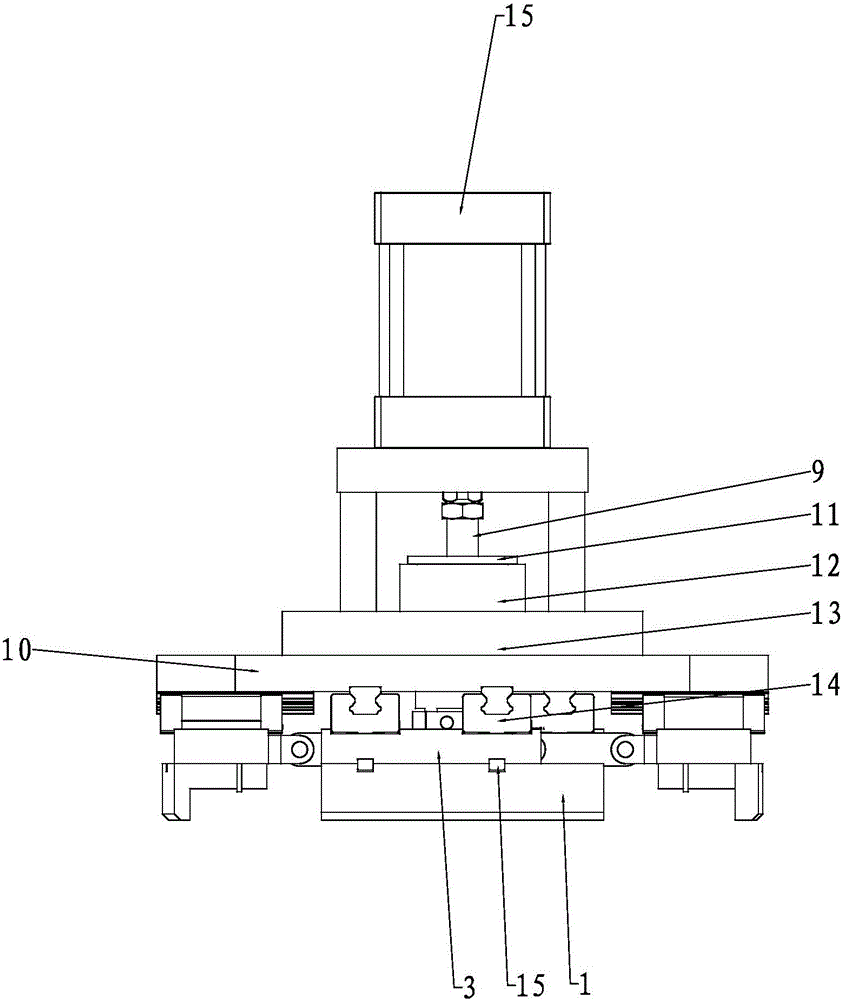

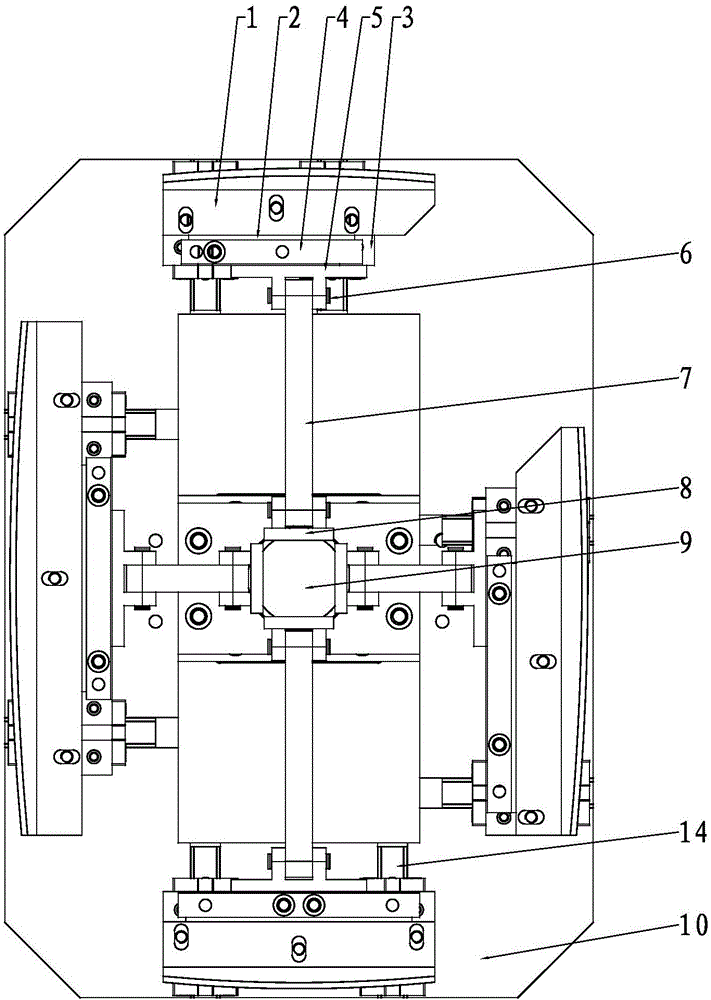

[0015] Such as Figure 1~2 As shown, the present invention mainly comprises chassis 10, and chassis 10 lower surface front end, rear end, left end, right end are provided with a slide rail 14 respectively, and a translational plate 3 is slidably installed in each slide rail 14, and each translational plate 3 The outer end is connected with a positioning block 1 through a fixing bar 4 .

[0016] An adjusting gasket 2 is provided between the translation plate 3 and the positioning block 1, and the gap between the translation plate 3 and the positioning block 1 can be adjusted by changing the adjusting gasket 2 of different thickness sizes or increasing or decreasing the number of the adjusting gaskets 2. Adjust the position of the positioning block 1 according to the actual size of the end cover, so that the mechanism can position the end cover and fix ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com