A kind of direct borohydride fuel cell cell activation method

A borohydride and fuel cell technology, applied in fuel cells, fuel cell additives, fuel cell control, etc., can solve the problems of high fuel consumption, low fuel utilization, low battery performance, etc., to achieve simple system and eliminate dependence performance and simplify the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

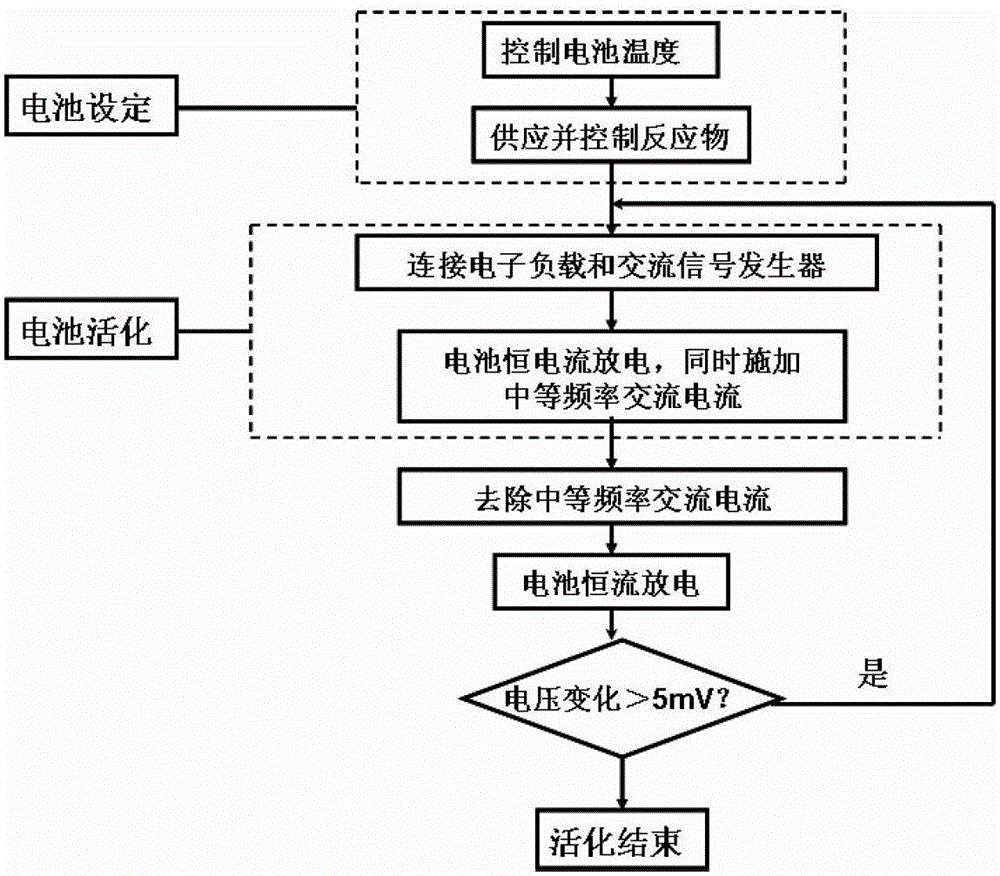

[0055] Set the effective area to 5cm 2 The single-piece membrane electrode for DBFC and the corresponding flow field plate, current collecting plate and end plate are assembled into a DBFC single cell. The assembly torque of the battery is 2.5Nm. Activate the single cell as follows:

[0056] The first part of the battery settings: (1) Using circulating water to control the battery temperature to 50±1℃; (2) Supplying the battery anode with 2MNaOH stabilized normal temperature sodium borohydride aqueous solution, NaBH 4 The concentration is 1M, the flow rate is 1mlmin -1 ; Pass O to the battery cathode 2 , The inlet pressure is controlled to 0.025±0.002MPa, the battery outlet is O 2 Flow rate control is 17.5±0.5mlmin -1 . The reactant does not circulate;

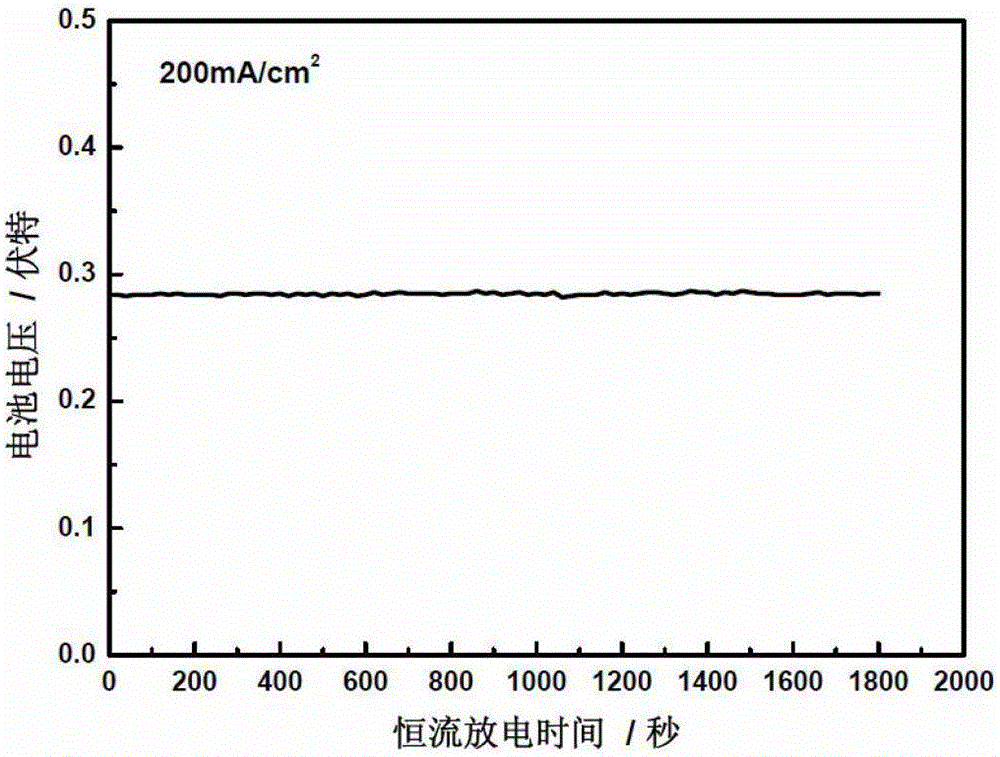

[0057] The second part of battery activation: (1) Connect the positive and negative terminals of the battery to the corresponding terminal of the electronic load; (2) Connect the terminal of the AC signal generator to the battery,...

Embodiment 2

[0062] Set the effective area to 5cm 2 The single-piece membrane electrode for DBFC and the corresponding flow field plate, current collecting plate and end plate are assembled into a DBFC single cell. The assembly torque of the battery is 2.5Nm. The single cell is activated according to the activation method provided by the present invention.

[0063] The first part of the battery settings: (1) Using circulating water to control the battery temperature to 30±1℃; (2) Supplying the battery anode with an aqueous solution of potassium borohydride stabilized by 0.5M NaOH at room temperature, KBH 4 Concentration is 3M, flow rate is 5mlmin -1 ; Pass 3MH to the battery cathode 2 SO 4 Stable hydrogen peroxide aqueous solution, H 2 O 2 The concentration is 2M, the flow rate is 5mlmin -1 . The reactants are not recycled.

[0064] The second part of battery activation: (1) Connect the positive and negative terminals of the battery to the corresponding terminal of the electronic load; (2) Con...

Embodiment 3

[0069] Set the effective area to 5cm 2 The single-piece membrane electrode for DBFC and the corresponding flow field plate, current collecting plate and end plate are assembled into a DBFC single cell. The assembly torque of the battery is 2.5Nm. The single cell is activated according to the activation method provided by the present invention.

[0070] The first part of the battery settings: (1) Using circulating water to control the battery temperature to 80±1℃; (2) Supplying the battery anode with an aqueous solution of potassium borohydride stabilized by 5MNaOH at room temperature, NaBH 4 The concentration is 0.5M, the flow rate is 3mlmin -1 ; Pass O to the battery cathode 2 , The inlet pressure is controlled to 0.005±0.002MPa, the battery outlet is O 2 Flow rate control is 17.5±0.5mlmin -1 .

[0071] The second part of battery activation: (1) Connect the positive and negative terminals of the battery to the corresponding terminal of the electronic load; (2) Connect the terminal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com