Flexible crystalline silicon solar assembly

A technology for solar modules and curved crystals, applied in semiconductor devices, electrical components, photovoltaic power generation, etc., can solve the problems of fragile, unsuitable environment with uneven surface, limited rigidity of crystalline silicon solar cells, etc., and achieves a simple process. , the effect of breaking through the complexity and high social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to enable those skilled in the art to better understand the technical solution of the present invention, and to make the above-mentioned purpose, features and advantages of the present invention more obvious and comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings.

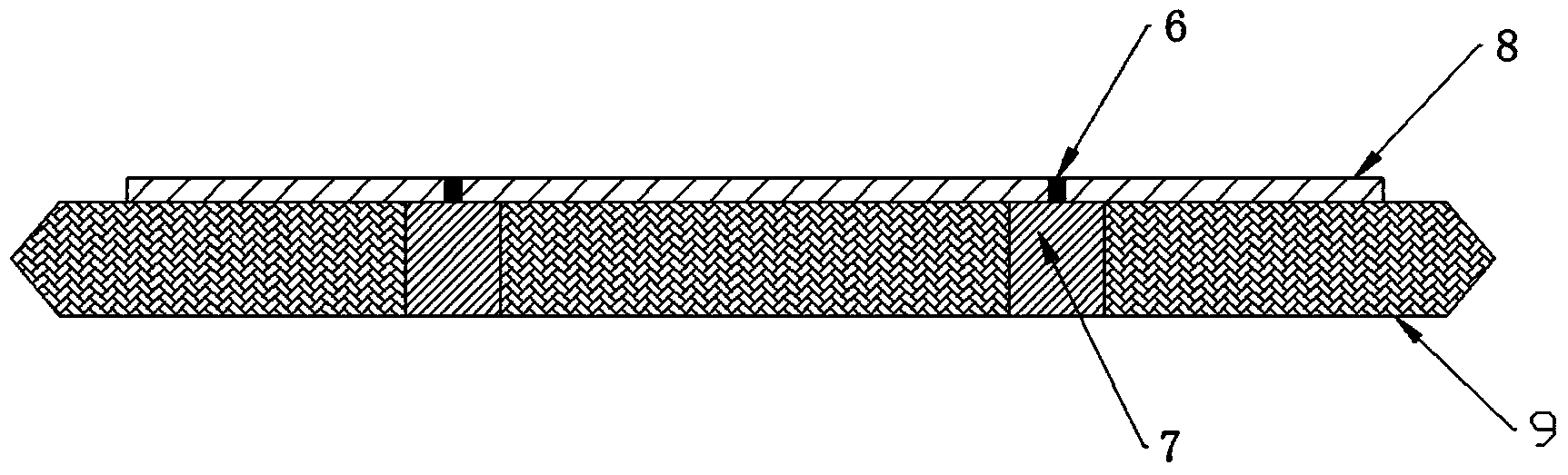

[0026] Prepare the full-page PCB module according to the design requirements, and at the same time, electrically connect the crystalline silicon solar cells (8) according to the cell gap required by the design, the distance between the PCB modules is the same as the gap between the cells, and then connect them The battery strings are positioned on the full-page PCB module, so that each battery slice corresponds to each PCB module (9), and the connection tin strip (6) between the battery slices corresponds to the slot of the PCB (7), such as figure 2 .

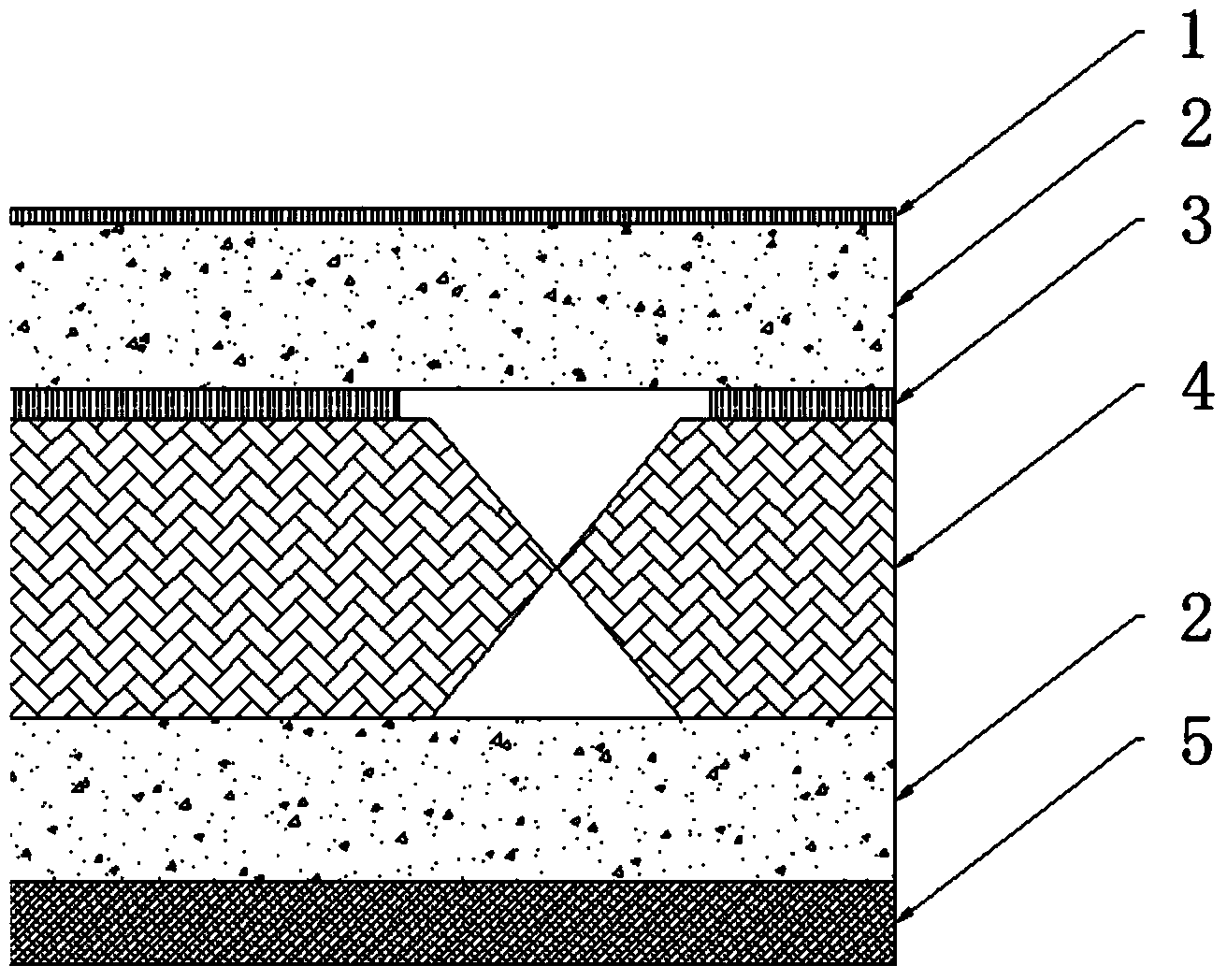

[0027] Follow the sequence from top to bottom of high-transparency front ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com