Solar photovoltaic module tracking device and installing method thereof

A solar photovoltaic and tracking device technology, applied in the field of photovoltaic trackers, can solve the problems of large and inconvenient solar module equipment, and achieve the effect of reducing work difficulty, installation time and installation difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

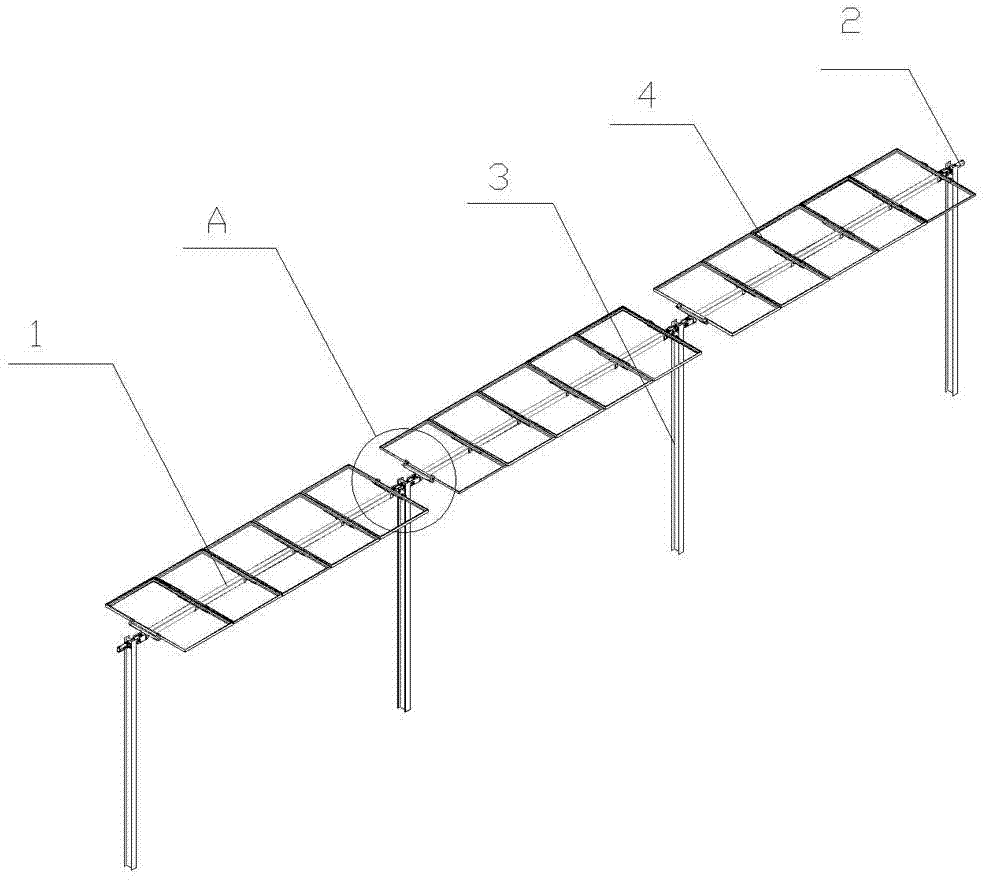

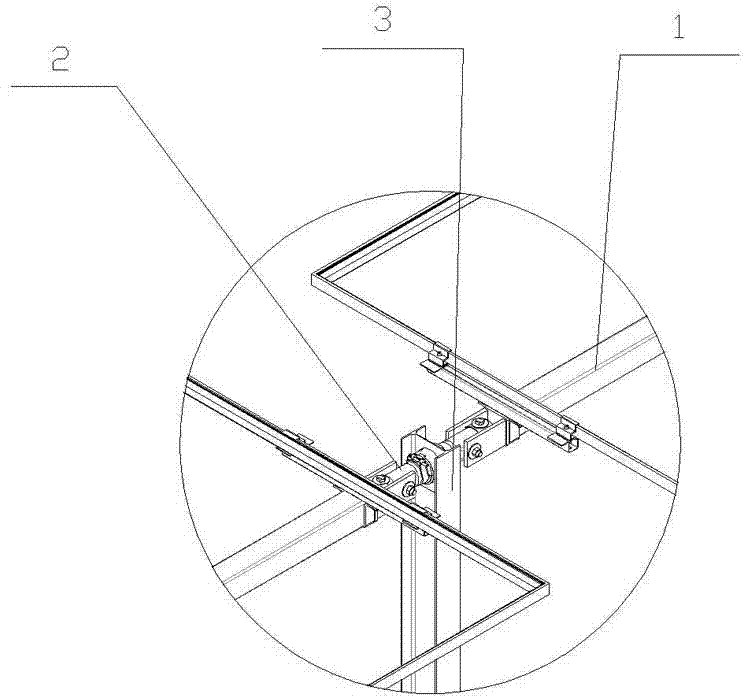

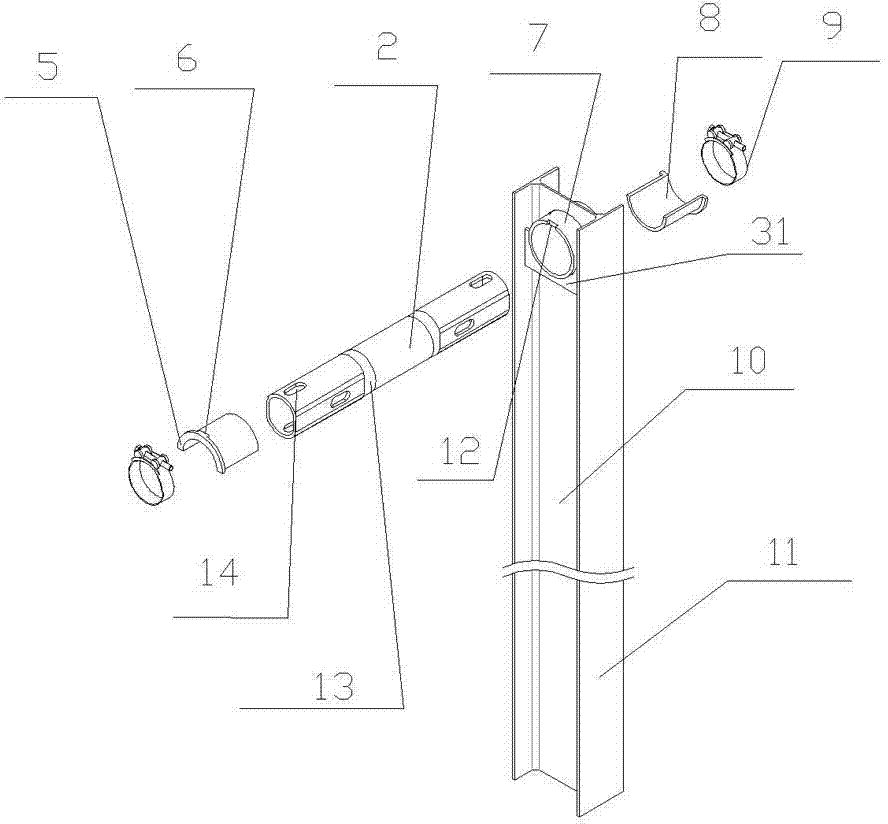

[0031] Such as figure 1 and 2 As shown, a solar photovoltaic module tracking device includes a column combination and a spindle combination. The column combination includes a column 3 with an "H" shape in cross section, a bearing structure, a connecting shaft 2, etc.; the spindle assembly includes a spindle 1, a beam 20, a photovoltaic module 4, and the like. Between the two columns 3 is a main shaft 1 , on which a photovoltaic module 4 is fixed, and two adjacent main shafts 1 are connected by a connecting shaft 2 , and the connecting shaft 2 is fixed on the column 3 . Such as image 3 As shown, the column 3 includes a column flange 10 and a column flange 11 parallel to each other on both sides of the column flange 10. A circular through hole is opened in the center of the upper end of the column flange 10, and a cylindrical bearing seat is welded in the through hole. 7. The outer edge of the bearing seat 7 is welded on the column edge plate 10. There are two rib plates 31 ...

Embodiment 2

[0037] A method for installing a solar photovoltaic module tracking device,

[0038] The first step is to install the column combination: open a hole in the center above the column, weld the rib plate under the through hole of the column, and then weld the bearing seat. The split bearing is inserted from both ends of the bearing seat and fixed by the positioning structure. Then, a connecting shaft is inserted into the bearing, and the connecting shaft is fixed on the column by a hoop. The upper end surface of the column can still be used as the force-bearing surface of the piling equipment, and then the column with the bearing structure and the connecting shaft is driven into the ground with the piling equipment, and then the main shafts are connected together through the connecting shaft;

[0039] The second step is to install the spindle assembly: use the spindle hoop to install the beam on the connecting shaft, and then install the backing plate on the beam. Insert the nar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com