Dynamic detector for jacquard loom component

A technology of jacquard looms and detectors, applied in the field of textile machinery, can solve the problems of jacquard loom production rate drop, production quality decrease, and manual detection component error, so as to ensure the operation rate, production quality and accuracy High, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

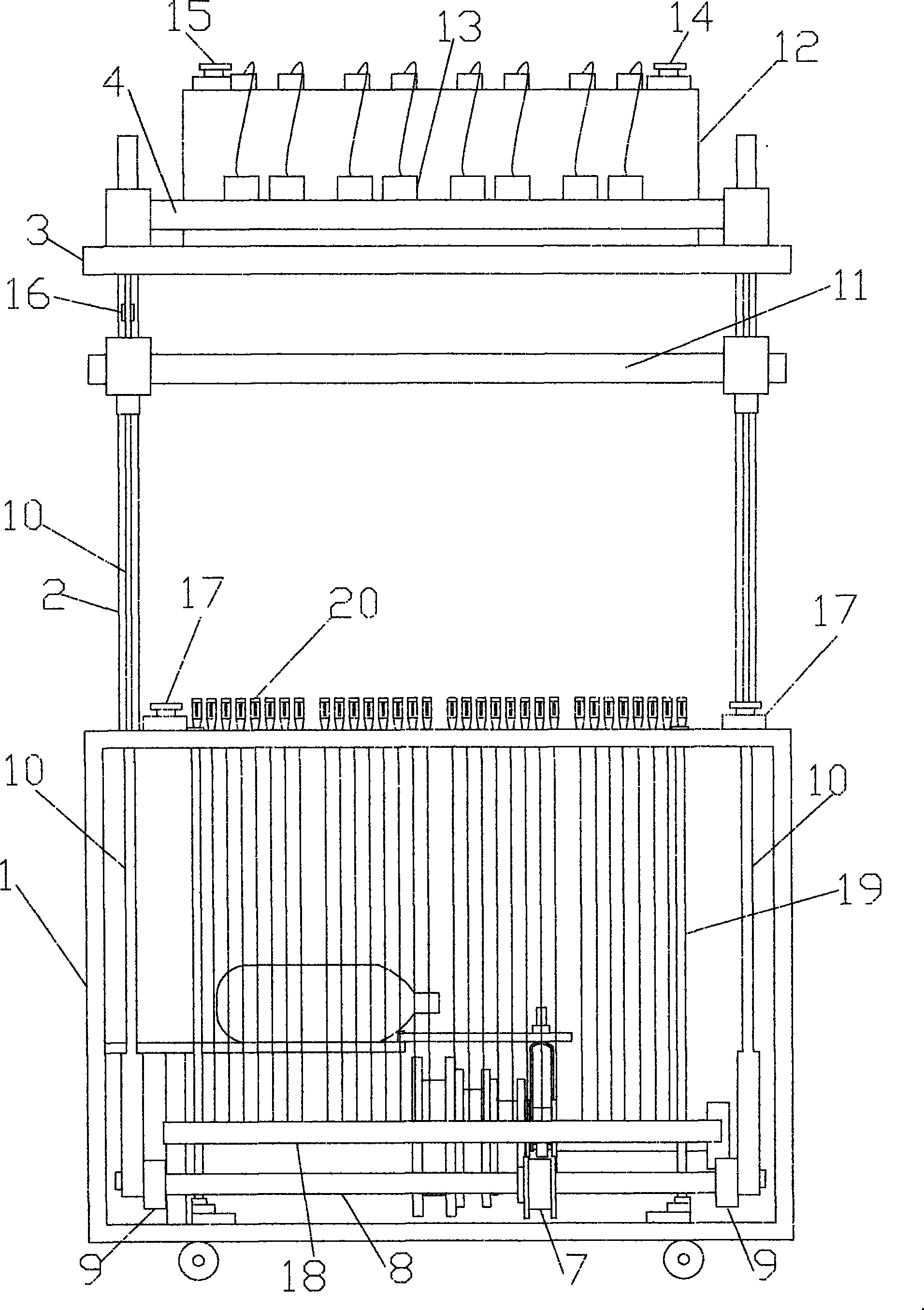

[0016] Such as figure 1 , figure 2 with image 3 As shown, a dynamic detector for jacquard loom components is mainly composed of a frame body, a transmission mechanism, a control mechanism and a detection mechanism. The frame 3 is fixed on the upper part of the column 2, and a component fixing frame 4 for placing components is fixed on the top frame 3; In the frame, the motor 5 is connected to the pulley set 6 through a belt, and a number of pulley grooves 61 with different diameters are arranged on the pulley set 6 to adjust the speed of the transmission mechanism. A tensioner 21 is set above the pulley set 6, and the tensioner 21 is fixed. On the extension plate 23, the extension plate 23 is fixed on the motor support 22, the pulley group 6 is connected to the transmission wheel 7 by a belt, and an eccentric wheel 9 is installed at both ends of the transmission wheel shaft 8 of the transmission wheel 7, and each eccentric wheel 9 The outer side is connected with a connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com